At its core, a hydraulic press is constructed from high-strength steel. This material forms the critical structural components, such as the frame and cylinders, which are designed to withstand the immense forces generated during operation. However, the press's power doesn't come from the steel alone; it's a system where solid materials contain and direct the force transmitted by a specialized fluid.

A hydraulic press is a system built on a fundamental trade-off: it uses strong, rigid materials like steel to create a structure capable of containing an incompressible hydraulic fluid. The true "work" is done by the fluid, with the steel components serving as the essential vessel and mechanism for force multiplication.

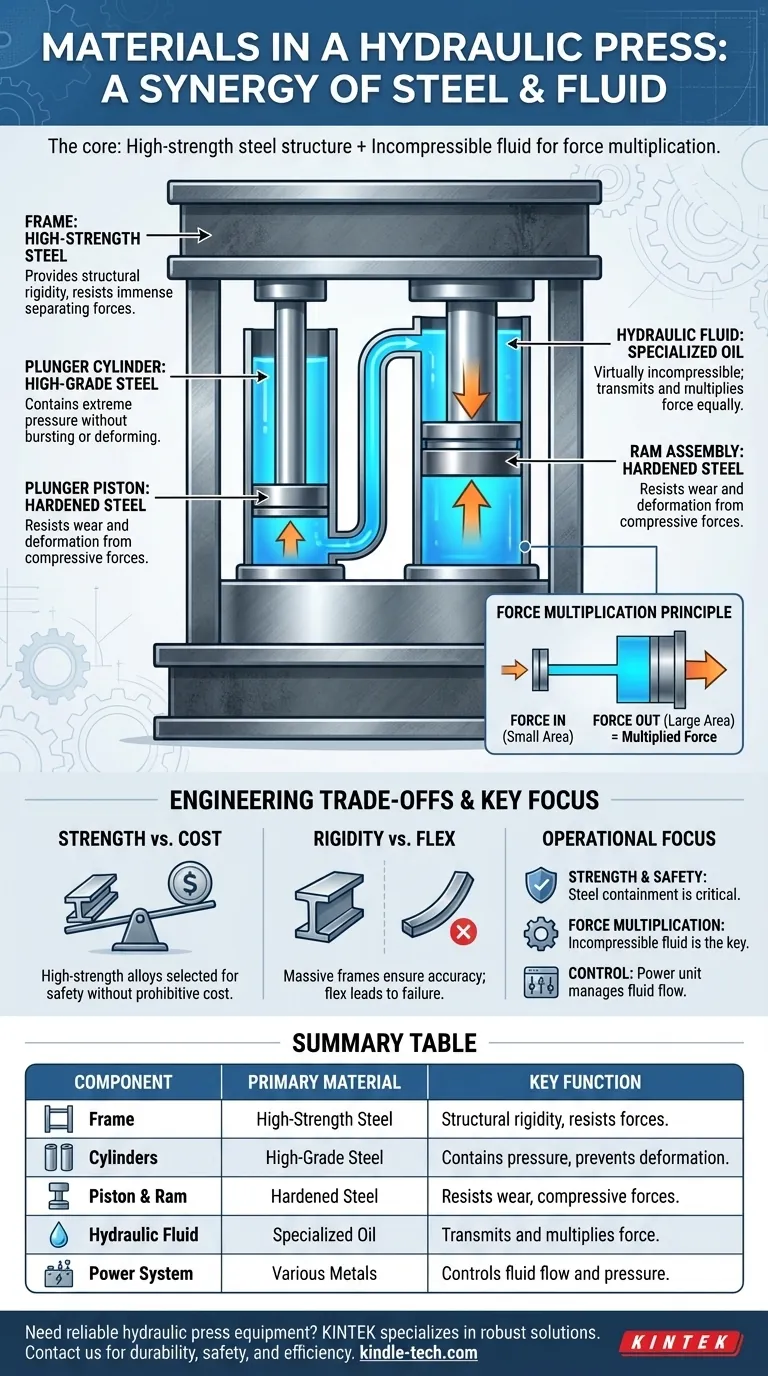

Deconstructing the Hydraulic Press: Core Components and Their Purpose

To understand why specific materials are used, we must first look at the main components of the press. Each part serves a distinct function and has material requirements tailored to its role.

The Frame: The Structural Backbone

The frame is the main structure that holds the entire assembly together. Its primary job is to provide strength and rigidity, resisting the immense separating forces that occur when the press is under load. For this reason, it is built from heavy-duty, high-strength steel.

The Hydraulic Cylinders (Ram and Plunger)

A hydraulic press has two interconnected cylinders: a small one (the plunger) and a large one (the ram). These cylinders contain the hydraulic fluid under extreme pressure. They are precision-machined from high-grade steel to prevent any possibility of bursting or deforming.

The Piston and Ram Assembly

Inside the cylinders are pistons that move to transmit force. The ram is the larger moving component that presses down on the workpiece. These components are made of hardened steel to resist wear, deformation, and the incredible compressive forces they exert.

The Hydraulic Fluid: The Force Multiplier

While not a solid material, the hydraulic fluid (typically a specialized oil) is arguably the most critical working medium. Its key property is that it is virtually incompressible. When pressure is applied to the fluid in the small plunger cylinder, that same pressure is transmitted equally throughout the fluid, acting on the much larger surface area of the ram. This is what multiplies the force.

The Power System and Controls

A pump creates the initial pressure in the hydraulic fluid. This power unit, along with a system of directional control valves, manages the flow of high-pressure oil to extend or retract the ram. These systems are complex assemblies of various metals designed for high-pressure fluid control.

Understanding the Key Trade-offs

The design of a hydraulic press is a masterclass in engineering trade-offs. The choice of materials is not just about picking the strongest option, but balancing performance, safety, and cost.

Strength vs. Cost

The frame and cylinders must be strong enough to operate safely with a significant margin of error. While exotic steel alloys could provide even greater strength, designers select high-strength carbon or alloy steels that offer the necessary performance without making the machine prohibitively expensive.

Rigidity vs. Flex

Under tons of force, even thick steel can flex. The frame of a hydraulic press must be exceptionally rigid to ensure that the force is applied accurately and evenly. Any flex in the frame can lead to misaligned parts and failed pressings. This is why the frames are so massive and heavily constructed.

Fluid Properties Matter

The choice of hydraulic fluid is not arbitrary. It must resist breaking down under high heat and pressure, have the correct viscosity to flow properly without leaking, and be as incompressible as possible to transmit force efficiently.

Applying This to Your Understanding

Your specific interest in the materials of a hydraulic press likely relates to understanding its strength, its function, or its operation.

- If your primary focus is strength and safety: Know that the high-strength steel used for the frame and cylinders is the critical element ensuring the machine can safely contain the immense pressures required for its work.

- If your primary focus is force multiplication: Understand that the magic happens because an incompressible hydraulic fluid transmits pressure from a small cylinder to a large one, a principle that requires a perfectly sealed and robust steel containment system.

- If your primary focus is operational control: Recognize that the power unit and valve system are the brains of the operation, precisely managing the flow of the hydraulic fluid to control the ram's movement and force.

Ultimately, a hydraulic press is an elegant system where robust physical materials provide the necessary structure for hydraulic principles to generate extraordinary power.

Summary Table:

| Component | Primary Material | Key Function |

|---|---|---|

| Frame | High-Strength Steel | Provides structural rigidity and resists immense separating forces. |

| Cylinders (Ram & Plunger) | High-Grade Steel | Contains hydraulic fluid under extreme pressure without deforming. |

| Pistons & Ram | Hardened Steel | Resists wear and deformation from compressive forces. |

| Hydraulic Fluid | Specialized Oil | Virtually incompressible fluid that transmits and multiplies force. |

| Power System | Various Metals (Pumps, Valves) | Controls the flow and pressure of the hydraulic fluid. |

Need a reliable hydraulic press for your lab or production line? The right equipment is built with the right materials. At KINTEK, we specialize in robust lab equipment and consumables, ensuring your hydraulic press is durable, safe, and efficient. Contact our experts today to find the perfect solution for your application and experience the KINTEK difference in quality and performance.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- What is the use of KBr? Master Sample Prep for Accurate IR Spectroscopy

- What role does a laboratory hydraulic press play in the preparation of solid electrolyte pellets? Ensure Data Accuracy

- What is the pellet technique in IR? Master Solid Sample Preparation for Clear Spectroscopy

- Why use KBr for IR? Achieve Clear, Unobstructed Spectra for Solid Samples

- How hot is a hydraulic press? Understanding the Critical Heat in Your Hydraulic System