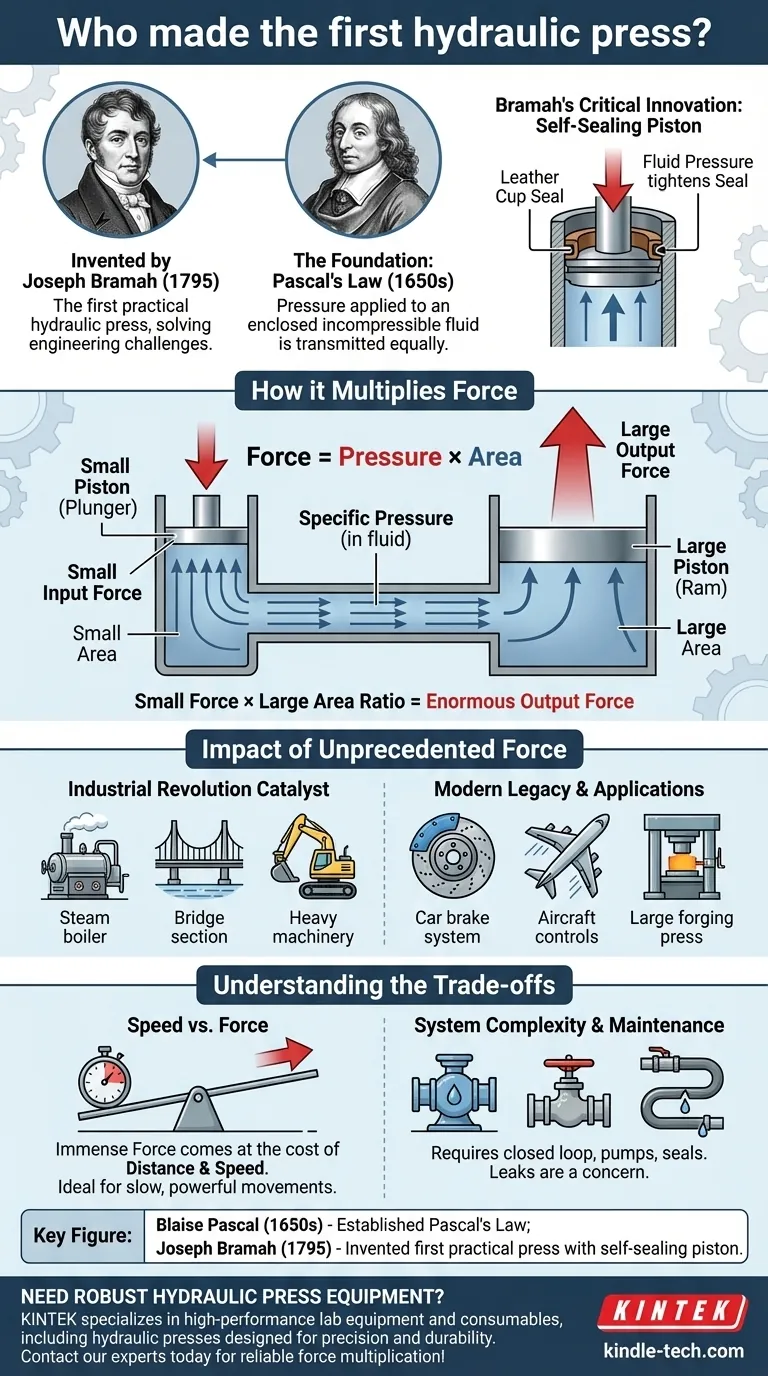

The first practical hydraulic press was invented by the English inventor and locksmith Joseph Bramah in 1795. While the underlying scientific principle had been established over a century earlier, Bramah was the one who solved the engineering challenges to create a functional machine that could multiply force on an unprecedented scale, becoming a cornerstone of the Industrial Revolution.

The invention of the hydraulic press was not merely the creation of a new machine. It was the successful application of a fundamental law of physics—Pascal's Law—to solve a practical industrial problem, unlocking a new frontier of force generation that fundamentally changed manufacturing.

From Scientific Principle to Industrial Powerhouse

The story of the hydraulic press is a perfect example of how a scientific discovery can lay dormant for decades before an engineer translates it into a world-changing technology.

The Foundation: Pascal's Law

The theoretical groundwork was laid by French mathematician and physicist Blaise Pascal in the 1650s.

Pascal's Law states that pressure applied to an enclosed, incompressible fluid is transmitted equally and undiminished to every part of the fluid and the walls of its container.

Think of it as a liquid lever. A small force applied over a small area generates a specific pressure. That same pressure, acting on a much larger area, produces a proportionally larger output force.

Joseph Bramah's Critical Innovation

Joseph Bramah was a brilliant and practical inventor. His genius was not in discovering the principle, but in making it work reliably under immense pressure.

The primary challenge was preventing fluid from leaking past the pistons. Bramah devised a self-sealing leather cup seal that pressed more tightly against the cylinder wall as the fluid pressure increased, creating a near-perfect seal.

This elegant solution to a difficult engineering problem is what made the high-pressure hydraulic press a reality.

How the Bramah Press Multiplies Force

The mechanism is elegantly simple and based on the formula Force = Pressure × Area.

- A small input force is applied to a piston with a small surface area (the plunger).

- This creates a specific pressure within the sealed hydraulic fluid (typically oil or water).

- According to Pascal's Law, this exact pressure is transmitted throughout the entire fluid.

- This pressure then acts upon a second piston with a much larger surface area (the ram).

- Because the area of the second piston is many times larger, the output force is multiplied by the same factor.

For example, if the large piston has 100 times the surface area of the small piston, the output force will be 100 times the input force.

The Impact of Unprecedented Force

The ability to easily generate enormous force had an immediate and profound effect on industry.

A Catalyst for the Industrial Revolution

Before the hydraulic press, shaping large metal parts was incredibly difficult. The Bramah press made it possible to bend thick steel plates for steam engine boilers, forge complex metal components, and press materials with a uniformity that was previously impossible.

It directly enabled advancements in shipbuilding, bridge construction, and machinery manufacturing.

Modern Legacy and Applications

The principle Bramah perfected is ubiquitous today. You interact with hydraulic systems constantly, often without realizing it.

Modern applications include vehicle braking systems, hydraulic jacks for lifting cars, aircraft flight controls, excavators and other heavy construction equipment, and massive industrial presses used for stamping car body panels.

Understanding the Trade-offs

While powerful, hydraulic systems are not a perfect solution for every problem. Their effectiveness comes with inherent compromises.

The Speed vs. Force Compromise

The immense force multiplication comes at the cost of distance and speed. This is a direct consequence of the conservation of energy.

To move the large piston up by one inch, the small piston must be pushed down a much greater distance. Force is gained, but speed is sacrificed. This makes hydraulic presses ideal for slow, powerful, and deliberate movements, but less suitable for high-speed operations.

System Complexity and Maintenance

Hydraulic systems require a closed loop of fluid, pumps, valves, and high-pressure hoses and seals. This introduces complexity and potential points of failure.

Leaks are a common maintenance concern, and hydraulic fluid can be a contaminant. This overhead means that for simpler, lower-force tasks, a purely mechanical or electromechanical system is often a more efficient choice.

How to Frame This Knowledge

Understanding the origin of the hydraulic press provides a valuable lens through which to view technology and engineering.

- If your primary focus is on the history of technology: See Bramah's invention as the crucial link between 17th-century physics (Pascal) and 19th-century industrial machinery, demonstrating how theory enables practice.

- If your primary focus is on engineering principles: Focus on the concept of force multiplication through fluid pressure, a foundational form of mechanical advantage still central to machine design.

- If your primary focus is on practical applications: Recognize that the same principle that powered the Industrial Revolution now powers everything from your car's brakes to massive forging presses.

Ultimately, the story of the hydraulic press is a powerful lesson in how harnessing a simple law of nature can grant us the power to shape the world around us.

Summary Table:

| Key Figure | Contribution | Year |

|---|---|---|

| Blaise Pascal | Established Pascal's Law (theoretical foundation) | 1650s |

| Joseph Bramah | Invented the first practical hydraulic press with a self-sealing piston | 1795 |

Need robust hydraulic press equipment for your laboratory or manufacturing process? KINTEK specializes in high-performance lab equipment and consumables, including hydraulic presses designed for precision and durability. Our solutions help you achieve reliable force multiplication for material testing, sample preparation, and more. Contact our experts today to find the perfect hydraulic system for your needs!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

People Also Ask

- What is the advantage of KBr? Unmatched IR Transparency for Precise Spectroscopy

- Are hydraulic presses powered by water? Discover the critical role of hydraulic oil.

- How hot is a hydraulic press? Understanding the Critical Heat in Your Hydraulic System

- Why are KBr pellets used in FTIR? Achieve Clear, Accurate Solid Sample Analysis

- What is the pressed powder pellet method? A Guide to Accurate FTIR Sample Preparation