At its core, a hydraulic press is a tool for anyone who needs to apply immense, controlled force. While its applications range from scientific laboratories to massive industrial plants, its users all share a common goal: shaping, compressing, or assembling materials with a power that mechanical or human force alone cannot achieve. For example, in laboratories, it is commonly used to press powdered samples into thin, solid pellets for analysis.

The true value of a hydraulic press isn't defined by a single industry, but by its mastery of a fundamental principle: using fluid pressure to generate massive, controllable force. This single capability makes it indispensable for any task requiring the compacting, shaping, assembling, or testing of materials.

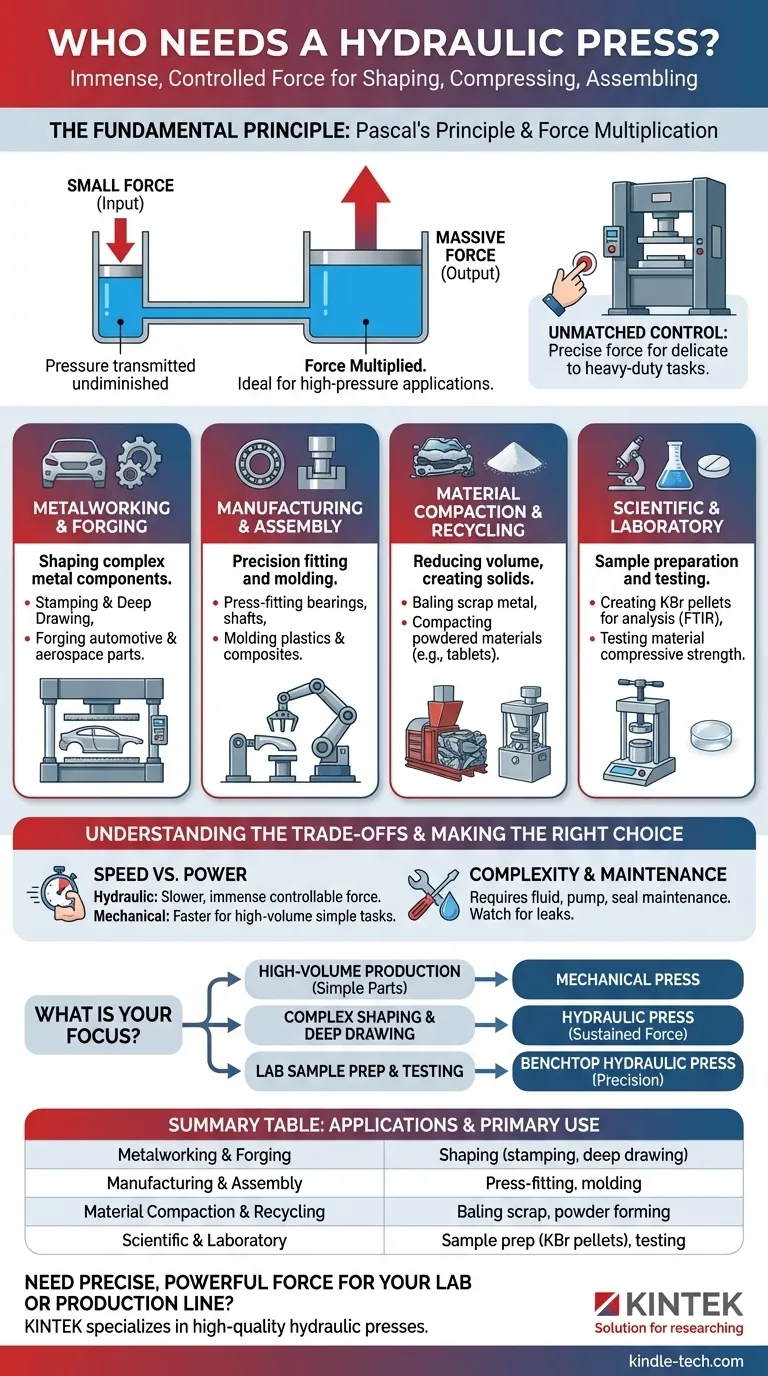

The Fundamental Principle: Why a Hydraulic Press is So Powerful

A hydraulic press operates on a simple yet profound concept known as Pascal's Principle. Understanding this is key to seeing why it's so widely adopted.

Pascal's Principle in Action

This principle states that pressure applied to an enclosed fluid is transmitted undiminished to every portion of the fluid and the walls of the containing vessel.

A hydraulic press uses two connected cylinders of different sizes, filled with an incompressible fluid like oil. A small force applied to a small piston generates a certain pressure in the fluid.

This same pressure then acts on a much larger piston, generating a proportionally larger force. This is how a small input force is multiplied into a massive output force.

Unmatched Force and Control

The primary advantage of a hydraulic system is not just raw power, but the precision with which that power can be applied.

The force can be held constant for long periods, applied slowly, and controlled accurately by regulating the fluid pressure. This makes it ideal for delicate operations and complex shaping processes.

Key Industrial and Scientific Users

The ability to multiply force makes the hydraulic press a cornerstone tool across numerous fields, each leveraging this capability for a specific purpose.

Metalworking and Forging

This is the most common industrial application. Users in the automotive, aerospace, and manufacturing sectors use large-scale hydraulic presses for forging, stamping, and deep drawing.

These processes shape raw metal blanks into complex parts like car body panels, engine components, and structural beams by applying thousands of tons of controlled force.

Manufacturing and Assembly

In many assembly lines, components must be tightly fitted together. A hydraulic press is used for press-fitting bearings, shafts, and other parts with extreme precision.

It is also used in molding applications for plastics, composites, and other materials, compressing them into a mold to form a final product.

Material Compaction and Recycling

The immense force of a hydraulic press is perfect for reducing the volume of materials. Scrap metal yards use them to crush cars and other metallic waste into dense, manageable bales.

This same principle is used to form powdered materials into solid forms, such as in the creation of ceramic components or pharmaceutical tablets.

Scientific and Laboratory Applications

On a much smaller scale, benchtop hydraulic presses are essential tools for scientists and technicians.

As noted, they are used for sample preparation, such as creating KBr (potassium bromide) pellets for infrared spectroscopy (FTIR), which requires the sample to be compressed into a thin, transparent film. They are also used in materials science to test the compressive strength of specimens.

Understanding the Trade-offs

While incredibly powerful, the hydraulic press is not the right tool for every job. Its design comes with inherent trade-offs that are critical to understand.

Speed vs. Power

Hydraulic presses are masters of force but are generally slower than their mechanical counterparts. The movement of fluid and the time it takes to build pressure limit their cycle speed.

For high-volume, repetitive tasks like simple stamping, a faster mechanical press is often more efficient.

Complexity and Maintenance

These systems rely on hydraulic fluid, pumps, high-pressure hoses, and seals. This introduces a level of complexity that requires regular maintenance.

Fluid leaks are a potential issue, demanding a clean and well-maintained operating environment. The fluid itself must also be kept free of contaminants to ensure system longevity.

Making the Right Choice for Your Goal

Selecting the right tool depends entirely on the task's specific demands for force, speed, and precision.

- If your primary focus is high-volume production of simple stamped parts: A mechanical press is likely the faster and more efficient choice.

- If your primary focus is shaping thick, complex components or performing deep-draw operations: The sustained, controllable force of a hydraulic press is essential.

- If your primary focus is laboratory sample preparation or materials testing: A benchtop hydraulic press provides the necessary precision and force in a compact form factor.

Understanding this core principle of controlled force transforms the hydraulic press from a specific machine into a versatile solution for a fundamental engineering challenge.

Summary Table:

| Industry/Application | Primary Use of Hydraulic Press |

|---|---|

| Metalworking & Forging | Shaping metal parts (stamping, deep drawing) |

| Manufacturing & Assembly | Press-fitting components, molding plastics/composites |

| Material Compaction & Recycling | Baling scrap metal, forming powdered materials |

| Scientific & Laboratory | Preparing samples (e.g., KBr pellets for FTIR), materials testing |

Need precise, powerful force for your lab or production line? KINTEK specializes in high-quality hydraulic presses for laboratory and industrial applications. Whether you're compacting powdered samples for analysis or shaping complex components, our equipment delivers the controlled force you need. Contact us today to find the perfect hydraulic press solution for your specific goals!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic Laboratory Heat Press Machine

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- How many types of presses are there? A Guide to Mechanical, Hydraulic, Servo & More

- Why is a laboratory hydraulic press with a vacuum suction system used for molding thermal insulation material? Find out!

- What are the parts of a manual hydraulic press? A Guide to Its Core Components and Operation

- Why is a laboratory hydraulic press used for Diamond/Copper preforms? Ensure Precise Alignment and Density

- Why is powder metallurgy limited to small parts? The Compaction & Cost Challenges Explained

- Which forging press would be best for producing very large parts? Unmatched Force for Massive Components

- What is forging in hydraulic press? Master Controlled Metal Forming with Sustained Pressure

- What is the maximum operating temperature of a water based hydraulic fluid? Ensure Fire Safety and System Reliability