In most modern contexts, an electric arc furnace (EAF) is considered superior to a traditional blast furnace (BF) due to its significantly lower capital cost, greater operational flexibility, and smaller environmental footprint. EAFs function like massive recycling plants, melting scrap steel with high-power electric arcs, which allows for faster production cycles and the ability to operate efficiently at a smaller scale.

The choice between an Electric Arc Furnace and a Blast Furnace is a strategic decision between two fundamentally different production philosophies. EAFs represent an agile, recycling-based model, while Blast Furnaces represent a large-scale, raw-material-based industrial process.

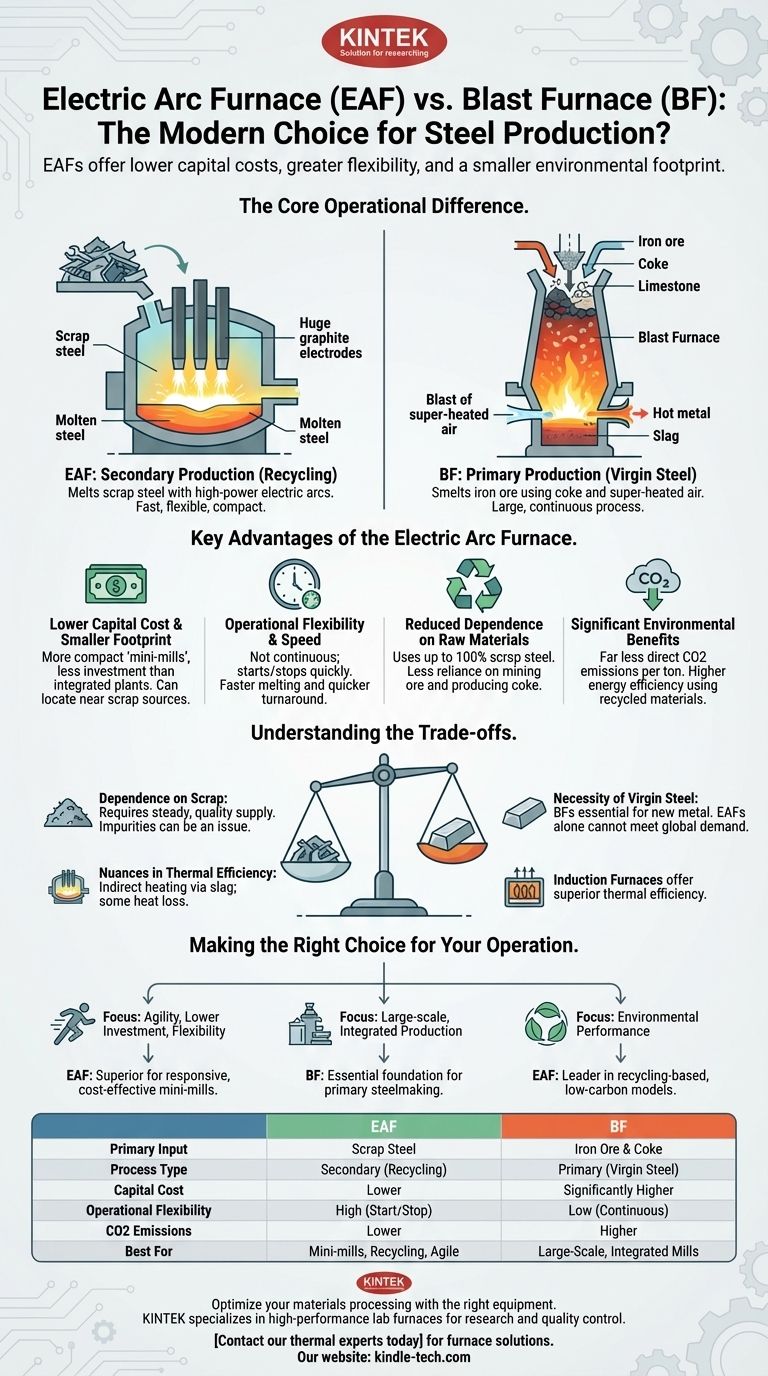

The Core Operational Difference

To understand why one is chosen over the other, you must first understand their distinct functions. They are not interchangeable tools; they are the anchors of two separate steel production routes.

How a Blast Furnace Works

A blast furnace is the first step in primary steel production. It is a massive, continuously operating chemical reactor that smelts iron ore.

Super-heated air is "blasted" into the furnace to combust coke (a high-carbon fuel derived from coal), which melts iron ore and limestone into liquid iron, also known as "hot metal." This iron must then be further processed in a Basic Oxygen Furnace (BOF) to become steel.

How an Electric Arc Furnace Works

An electric arc furnace is the center of secondary steel production, which is essentially steel recycling. It does not use iron ore or coke.

Instead, it charges the furnace primarily with scrap steel. Huge graphite electrodes are lowered into the furnace, and an immense electric arc flows between them and through the metal, generating intense heat that melts the scrap. This molten steel can then be refined and cast directly.

Key Advantages of the Electric Arc Furnace

The EAF model offers several compelling advantages that align with modern economic and environmental pressures.

Lower Capital Cost and Smaller Footprint

An EAF plant costs substantially less to build than the integrated steel mill required for a blast furnace and its supporting coke ovens and basic oxygen furnace.

Because the equipment is more compact and self-contained, EAFs can be built as "mini-mills," which are smaller, more geographically distributed facilities that can be located closer to scrap sources and customers.

Operational Flexibility and Speed

EAFs are not designed for continuous operation. They can be started and stopped relatively quickly, which provides immense flexibility to respond to market demand and electricity price fluctuations.

They also heat up and melt steel much faster than a blast furnace can produce hot metal. This speed, combined with precise control over temperature, allows for quicker turnaround times.

Reduced Dependence on Raw Materials

The EAF process can use up to 100% scrap steel as its primary input. This dramatically reduces reliance on mining iron ore and producing coke, which are energy-intensive and environmentally damaging processes.

This model transforms steel from a single-use material into a continuously recyclable one, creating a more circular economy.

Significant Environmental Benefits

By avoiding the use of coke and the chemical reduction of iron ore, EAFs produce far less direct CO2 emissions per ton of steel compared to the traditional BF-BOF route.

Their higher energy efficiency, derived from using recycled material instead of starting from virgin ore, makes them a cornerstone of efforts to decarbonize the steel industry.

Understanding the Trade-offs

Despite its many advantages, the EAF is not a universal replacement for the blast furnace. Its effectiveness is dependent on specific conditions.

Dependence on Scrap Availability

The EAF model is entirely reliant on a steady, affordable supply of high-quality scrap steel. In regions where scrap is scarce or contaminated, operating an EAF can become economically unviable.

The quality of the final steel is also directly linked to the quality of the input scrap. Removing certain contaminants, like copper, can be difficult and expensive.

Necessity of Virgin Steel Production

A global steel industry cannot run on EAFs alone. Blast furnaces are essential for producing virgin steel from iron ore, introducing new metal into the global supply.

Without primary production from blast furnaces, the pool of available scrap for EAFs would eventually deplete. The two systems currently exist in a symbiotic relationship.

Nuances in Thermal Efficiency

While EAFs are highly efficient from a total process and energy perspective, their method of heating is not perfect. The heat from the electric arc must transfer to the metal, often through a layer of slag.

This is a form of indirect heating, and a significant amount of heat can be lost through the furnace walls and roof. Other technologies, like induction furnaces, can offer superior thermal efficiency by generating heat directly within the metal itself.

Making the Right Choice for Your Operation

Ultimately, the "better" furnace is the one that aligns with your strategic goals, resource availability, and market position.

- If your primary focus is agility, lower initial investment, and production flexibility: The Electric Arc Furnace is the superior choice for building a responsive and cost-effective mini-mill.

- If your primary focus is large-scale, integrated production from raw materials: The Blast Furnace remains the essential and proven foundation of the primary steelmaking route.

- If your primary focus is environmental performance and leveraging a circular economy: The EAF is the clear leader, enabling a business model built on recycling and significantly lower carbon emissions.

Choosing the right technology is about matching the tool to the industrial mission you intend to accomplish.

Summary Table:

| Feature | Electric Arc Furnace (EAF) | Blast Furnace (BF) |

|---|---|---|

| Primary Input | Scrap Steel | Iron Ore & Coke |

| Process Type | Secondary (Recycling) | Primary (Virgin Steel) |

| Capital Cost | Lower | Significantly Higher |

| Operational Flexibility | High (Start/Stop Easily) | Low (Continuous Operation) |

| CO2 Emissions | Lower | Higher |

| Best For | Mini-mills, Recycling, Agile Production | Large-Scale, Integrated Steel Mills |

Optimize your materials processing with the right equipment.

Whether your lab or pilot plant is involved in metallurgy, materials testing, or process development, choosing the right heating technology is critical for efficiency and results. KINTEK specializes in high-performance lab furnaces, including box furnaces, tube furnaces, and high-temperature models, designed to meet the precise thermal processing needs of research and quality control.

Let KINTEK be your partner in innovation. We provide the reliable equipment and expert support you need to push the boundaries of materials science.

Contact our thermal experts today to discuss your specific application and find the perfect furnace solution for your laboratory.

Visual Guide

Related Products

- Vertical Laboratory Tube Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

People Also Ask

- What protective gear is required when handling goods inside Ultra Freezers? Essential PPE for Extreme Cold Safety

- What is the temperature of a lab oven? A Guide to Selecting the Right Type for Your Application

- Why KBr pellets are used to prepare solid samples in FTIR? Achieve Clear, Reliable Solid Analysis

- Why is pre-treatment in high-temperature drying ovens required for alumina and graphite powders? Boost Spray Quality

- What is the function of a forced air drying oven in Ni/CN catalyst recovery? Maximize Reuse Efficiency

- What is the origin of sintering? Discover the Prehistoric Evolution of Thermal Fusion and Ancient Ceramics

- How does annealing affect material properties? Tailor Strength, Ductility & Conductivity

- What can physical Vapour deposition be used for? Enhance Durability and Performance with PVD Coatings