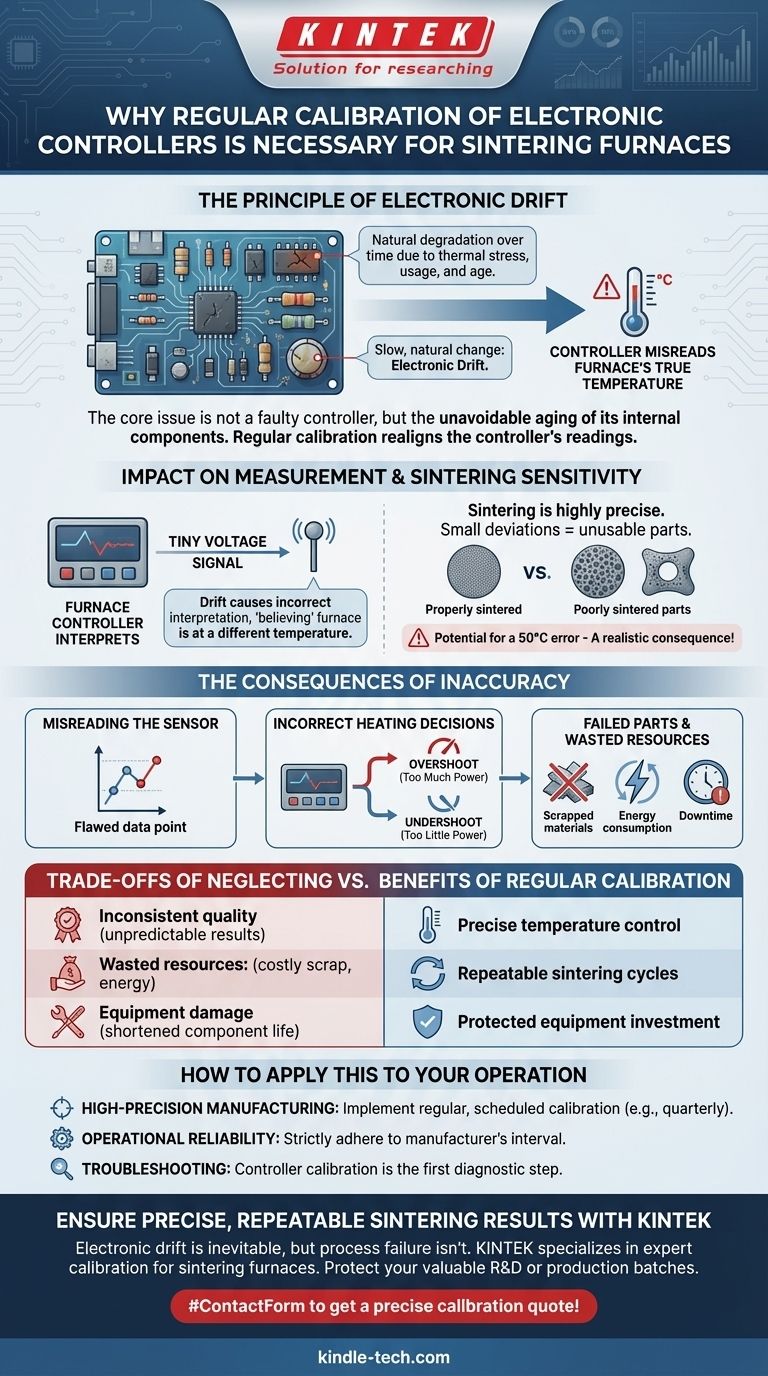

Regular calibration is essential for sintering furnaces because the electronic components within the controller naturally degrade over time. This degradation, known as electronic drift, causes the controller to misread the furnace's true temperature, leading to inaccurate and inconsistent heating cycles. Without calibration, this error can become significant, potentially deviating by as much as 50°C from the setpoint.

The core issue is not a faulty controller, but the unavoidable aging of its internal components. Regular calibration is the necessary maintenance that realigns the controller's readings with reality, ensuring the integrity and repeatability of your critical sintering process.

The Principle of Electronic Drift

What is "Drift"?

Electronic components, such as resistors and capacitors, are not perfectly stable over their lifetime. Their physical properties change subtly due to factors like thermal stress, usage, and age.

This slow, natural change is called electronic drift. It is an inherent characteristic of the hardware that makes up your furnace's controller.

The Impact on Measurement

A furnace controller doesn't measure temperature directly. It interprets a tiny voltage signal (millivolts) sent from a sensor, typically a thermocouple.

The controller's internal components form the reference circuit for interpreting this signal. As these components drift, the controller's interpretation of that constant signal becomes inaccurate. It begins to "believe" the furnace is at a different temperature than it actually is.

Why Sintering is So Sensitive

Sintering is a highly precise thermal process. The final density, strength, and dimensional accuracy of the material depend on holding specific temperatures for exact periods.

Even a small deviation from the required temperature profile can lead to under-sintered parts (porous, weak) or over-sintered parts (warped, excessive grain growth), rendering the entire batch unusable.

The Consequences of Inaccuracy

Misreading the Sensor

The entire control process begins with the temperature reading. If this initial data point is wrong due to controller drift, every subsequent action the controller takes will be based on flawed information.

Incorrect Heating Decisions

Based on this faulty data, the controller will apply either too much or too little power to the heating elements.

If the controller thinks the furnace is cooler than it is, it will apply more power, causing the furnace to overshoot the target temperature. If it thinks the furnace is hotter, it will apply less power, causing it to undershoot.

The 50°C Warning

The potential for a 50°C error is not a rare worst-case scenario; it is a realistic consequence of neglected maintenance. An error of this magnitude is catastrophic for any controlled sintering process, guaranteeing failed parts.

The Trade-offs of Neglecting Calibration

The Cost of Inconsistent Quality

An uncalibrated controller leads to unpredictable and non-repeatable results. Parts produced one week may have completely different material properties from those produced the next, even with the exact same settings. This introduces a major variable that undermines quality control.

The Risk of Wasted Resources

Every failed sintering run wastes three critical resources: expensive raw materials, significant amounts of energy, and valuable production time. The cost of a single scrapped batch often exceeds the cost of a proper calibration service.

The Potential for Equipment Damage

Consistently running a furnace hotter than intended can dramatically shorten the life of expensive components like heating elements and refractory insulation, leading to premature failure and costly repairs.

How to Apply This to Your Operation

Your approach to calibration should be a deliberate part of your quality assurance and preventative maintenance strategy.

- If your primary focus is high-precision manufacturing and quality control: Implement a regular, scheduled calibration (e.g., quarterly or semi-annually) using a certified, traceable reference instrument.

- If your primary focus is operational reliability and minimizing downtime: Strictly adhere to the manufacturer's recommended calibration interval outlined in your furnace's owner's manual.

- If you are troubleshooting inconsistent product outcomes: Controller calibration should be your first diagnostic step before investigating materials or other process variables.

Treating controller calibration as a non-negotiable part of your maintenance protocol is the most effective way to guarantee the precision and reliability of your sintering furnace.

Summary Table:

| Aspect | Impact of No Calibration | Benefit of Regular Calibration |

|---|---|---|

| Temperature Accuracy | Deviations up to 50°C from setpoint | Maintains precise temperature control |

| Process Consistency | Unpredictable, non-repeatable results | Guarantees repeatable sintering cycles |

| Product Quality | Under-sintered or over-sintered parts | Ensures final part density and strength |

| Operational Cost | Wasted materials, energy, and time | Prevents scrap batches and saves resources |

| Equipment Lifespan | Premature failure of heating elements | Protects your furnace investment |

Ensure your sintering furnace delivers precise, repeatable results.

Electronic drift is inevitable, but process failure isn't. KINTEK specializes in maintaining the precision of your lab equipment. Our expert calibration services for sintering furnaces use certified, traceable instruments to realign your controller, eliminate temperature errors, and protect your valuable R&D or production batches.

Don't let an uncalibrated controller compromise your quality and waste resources. Contact our lab equipment experts today to schedule a calibration and secure the integrity of your sintering process.

#ContactForm to get a precise calibration quote!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Spark Plasma Sintering Furnace SPS Furnace

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

People Also Ask

- What is the sintering time for zirconia? A Guide to Precise Firing for Optimal Results

- What is one of the newest applications for dental ceramics? Monolithic Zirconia for Full-Arch Bridges

- What is the temperature of sintering zirconia? Mastering the Protocol for Perfect Dental Restorations

- What are the white spots on zirconia after sintering? A Guide to Diagnosing and Preventing Defects

- Can you change the color of zirconia crowns? Understanding the Permanent Nature of Zirconia