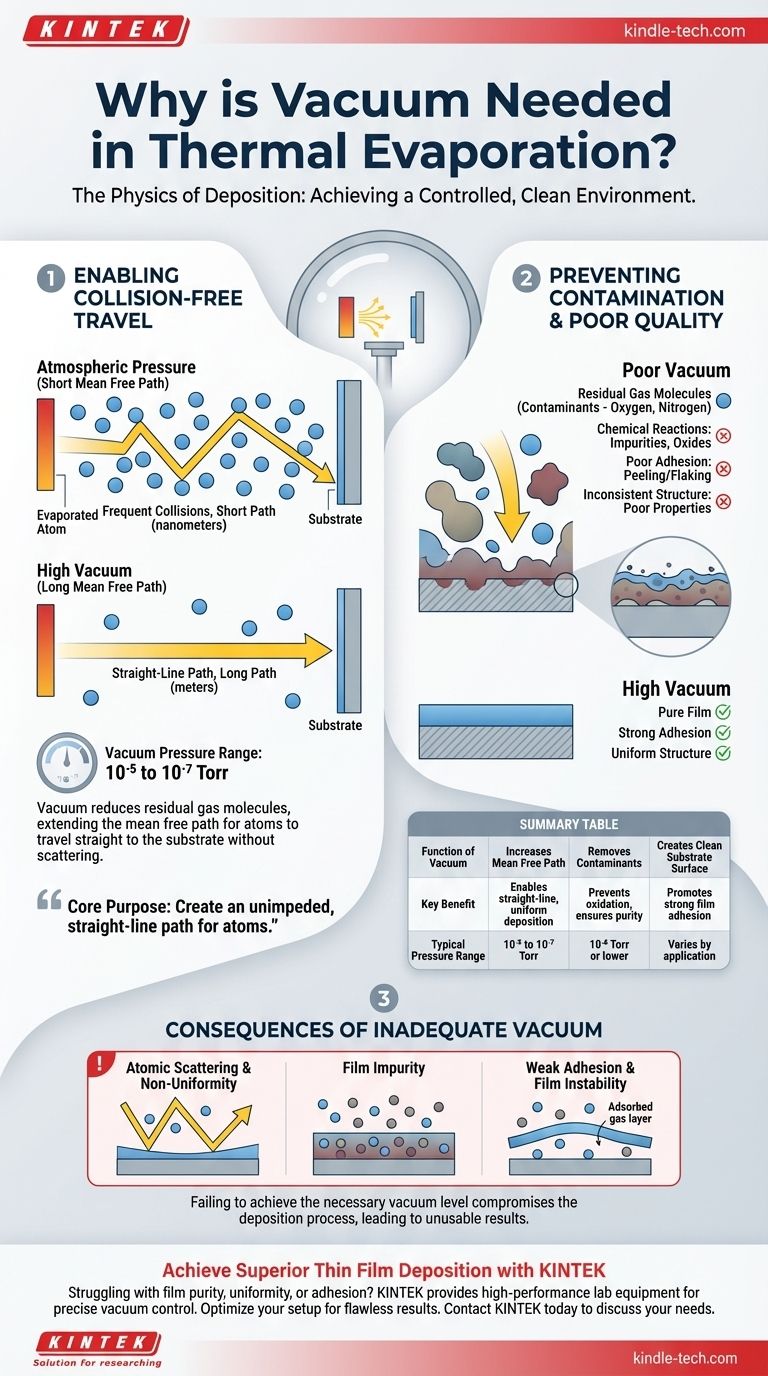

In thermal evaporation, a vacuum is essential for two primary reasons: it allows evaporated material to travel directly to the substrate without colliding with other molecules, and it removes contaminants that would otherwise ruin the quality and adhesion of the deposited film. This controlled, clean environment is the foundation of the entire process.

The core purpose of the vacuum is not just to remove air, but to create an unimpeded, straight-line path for atoms traveling from the source to the target. This ensures the resulting film is uniform, pure, and well-adhered to the substrate.

The Physics of Deposition: Why a Vacuum is Non-Negotiable

Thermal evaporation works by heating a source material until its atoms vaporize. These vaporized atoms then travel through a chamber and condense on a cooler substrate, forming a thin film. The vacuum is what makes this journey successful.

Enabling Collision-Free Travel

The most critical function of the vacuum is to increase the mean free path of the evaporated atoms.

The mean free path is the average distance a particle can travel before it collides with another particle. In normal atmospheric pressure, this distance is incredibly short, measured in nanometers.

By evacuating the chamber to a high vacuum—typically in the range of 10⁻⁵ to 10⁻⁷ Torr—the number of residual gas molecules (like nitrogen and oxygen) is drastically reduced.

This extends the mean free path to a meter or more. Since the distance from the source to the substrate is much shorter than this, the evaporated atoms can travel in a straight line, ensuring they arrive at the substrate without being scattered.

Preventing Contamination and Poor Film Quality

The second key function of the vacuum is to create an ultra-clean environment. Any residual gas molecules in the chamber are contaminants.

These contaminants can cause several problems:

- Chemical Reactions: Reactive gases like oxygen can react with the hot evaporated atoms mid-flight or on the substrate surface, forming unwanted oxides and impurities in the film.

- Poor Adhesion: Contaminants on the substrate surface can prevent the evaporated atoms from bonding properly, leading to a film that peels or flakes off easily.

- Inconsistent Structure: Unwanted molecules incorporated into the film disrupt its crystalline or amorphous structure, negatively affecting its optical, electrical, or mechanical properties.

The Consequences of an Inadequate Vacuum

Failing to achieve the necessary vacuum level directly compromises the deposition process and renders the results unusable for most applications. Understanding these failure modes highlights the vacuum's importance.

Atomic Scattering and Non-Uniformity

If the pressure is too high, the mean free path is too short. Evaporated atoms will collide with gas molecules, scattering them in random directions.

This prevents the "line-of-sight" deposition required for a uniform coating. The resulting film will have an inconsistent thickness and may not cover the substrate evenly.

Film Impurity

Without a proper vacuum, the deposition environment is "dirty." The vapor stream will be a mix of source material and residual atmospheric gases.

The final film will be heavily contaminated with oxides, nitrides, and other compounds, altering its fundamental properties. For applications in electronics or optics, this level of impurity is unacceptable.

Weak Adhesion and Film Instability

A poor vacuum leaves a layer of adsorbed gas molecules on the substrate surface. This layer acts as a barrier, preventing the deposited atoms from forming a strong, stable bond with the substrate.

The result is a film that adheres weakly and is prone to delamination or mechanical failure over time.

Applying This to Your Goal

The required vacuum level is directly tied to the desired quality of your thin film. Your specific application will determine how you approach this critical parameter.

- If your primary focus is high-purity films for electronics or optics: You must achieve a high or ultra-high vacuum (10⁻⁶ Torr or lower) to minimize contamination and ensure predictable material properties.

- If your primary focus is protective or decorative coatings: A more moderate high vacuum (around 10⁻⁵ Torr) may be sufficient, as minor impurities are less likely to affect the film's primary function.

- If you are troubleshooting a process with poor adhesion: An inadequate vacuum level or a contaminated chamber is one of the most likely root causes to investigate.

Ultimately, controlling the chamber environment through vacuum is the key to controlling the outcome of your deposition.

Summary Table:

| Function of Vacuum | Key Benefit | Typical Pressure Range |

|---|---|---|

| Increases Mean Free Path | Enables straight-line, uniform deposition | 10⁻⁵ to 10⁻⁷ Torr |

| Removes Contaminants | Prevents oxidation & ensures film purity | 10⁻⁶ Torr or lower (for high purity) |

| Creates Clean Substrate Surface | Promotes strong film adhesion | Varies by application |

Achieve Superior Thin Film Deposition with KINTEK

Struggling with film purity, uniformity, or adhesion in your lab? The quality of your thermal evaporation process hinges on precise vacuum control. KINTEK specializes in high-performance lab equipment, including vacuum systems and thermal evaporation sources, designed to meet the stringent demands of electronics, optics, and materials science research.

We provide the reliable, clean environment your deposition process requires. Let our experts help you optimize your setup for flawless results.

Contact KINTEK today to discuss your specific laboratory needs and discover the right solution for your research.

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- How are PECVD and CVD different? A Guide to Choosing the Right Thin-Film Deposition Process

- What is the difference between CVD and PVD process? A Guide to Choosing the Right Coating Method

- What is the difference between CVD and PECVD? Choose the Right Thin-Film Deposition Method

- What are the advantages of PECVD over CVD? Achieve High-Quality Thin Films at Lower Temperatures

- How plasma is generated in PECVD? A Step-by-Step Breakdown of the Process