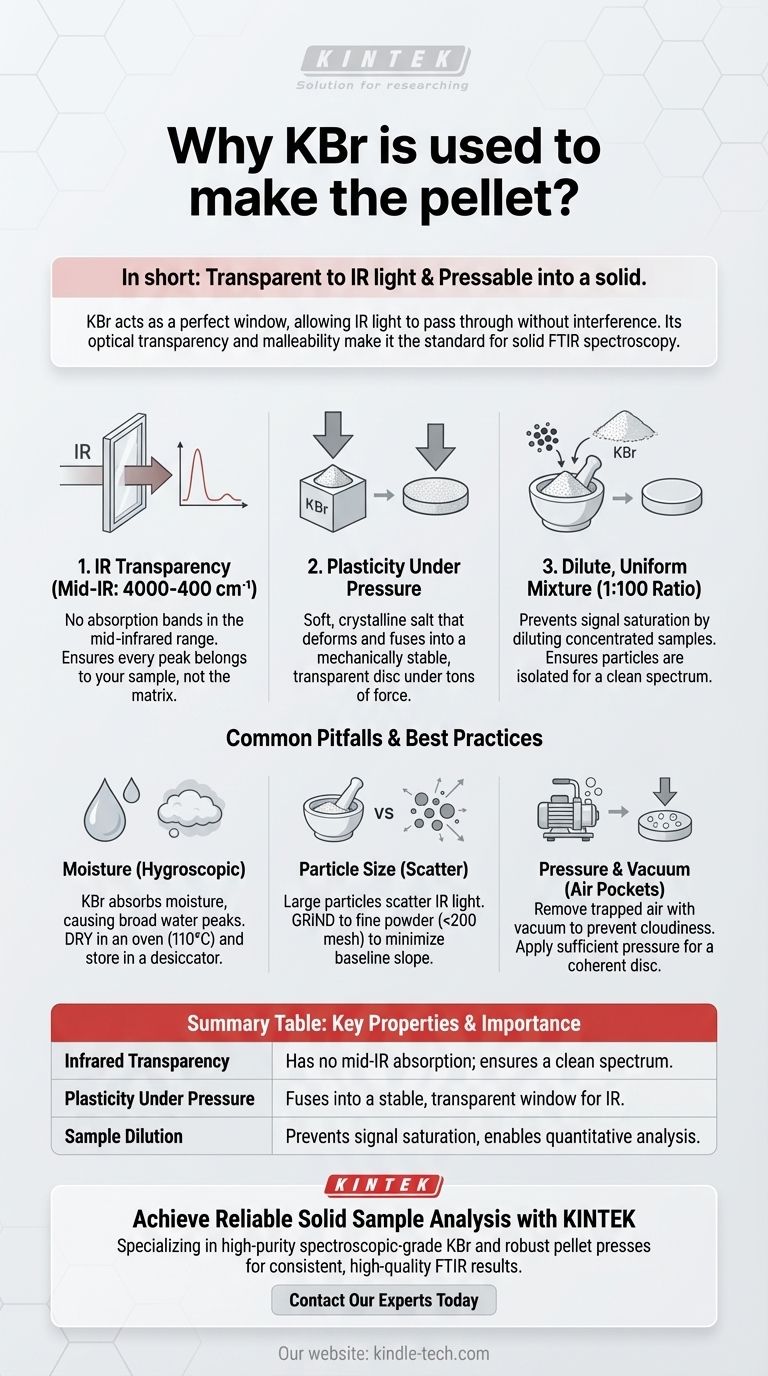

In short, Potassium Bromide (KBr) is used because it is transparent to infrared light and can be pressed into a solid, glass-like pellet. It acts as a perfect window, allowing the spectrometer's IR beam to pass through the sample without adding its own interfering signals. This unique combination of optical transparency and physical malleability makes it the standard for analyzing solid samples in FTIR spectroscopy.

The core challenge in analyzing a solid sample with infrared (IR) light is getting the light through it uniformly. KBr solves this by acting as an inert, transparent matrix that encases the finely ground sample, creating a solid, consistent medium for analysis.

The Role of KBr in IR Spectroscopy

To understand why KBr is the material of choice, we must look at its specific properties, which are perfectly suited for the demands of infrared analysis.

The Necessity of Infrared Transparency

The goal of IR spectroscopy is to measure which frequencies of infrared light a sample absorbs.

Therefore, the material holding the sample must not absorb IR light in the same region. KBr is ideal because it has no absorption bands in the mid-infrared range (typically 4000-400 cm⁻¹), which is the most information-rich region for organic and inorganic chemistry.

This property ensures that every peak you see in the final spectrum belongs to your sample, not the KBr matrix.

Plasticity Under Pressure

KBr possesses a crucial physical property: it is a soft, crystalline salt that deforms and flows under high pressure.

When finely ground KBr powder is put into a die and subjected to several tons of force, the individual crystals fuse together. This process forms a solid, semi-transparent or transparent disc that is mechanically stable.

This allows you to create a solid window that has your sample evenly distributed within it.

Creating a Dilute, Uniform Mixture

Most solid samples are too concentrated to analyze directly with IR spectroscopy; they would absorb all the light, resulting in a useless, saturated spectrum.

The KBr method involves grinding a tiny amount of sample with a much larger amount of KBr, typically at a 1:100 sample-to-KBr ratio. This thorough mixing creates a homogenous, dilute mixture.

When pressed, this results in a pellet where sample particles are isolated and dispersed evenly throughout the KBr matrix, ensuring a clean, high-quality spectrum.

Common Pitfalls and Best Practices

While the KBr pellet method is powerful, its success depends entirely on meticulous technique. Poor preparation is the most common source of error in solid-sample FTIR.

The Critical Impact of Moisture

KBr is hygroscopic, meaning it readily absorbs moisture from the atmosphere. Water has very strong, broad absorption bands in the IR spectrum.

If your KBr is not perfectly dry, you will see large water peaks in your spectrum, which can obscure important signals from your sample. For this reason, spectroscopic-grade KBr should always be dried in an oven (around 110 °C) before use and stored in a desiccator.

Achieving the Correct Particle Size

The clarity of the final pellet depends on minimizing light scattering. Large particles scatter IR light, leading to a sloping baseline and reduced signal quality.

Both the sample and the KBr must be ground to a very fine powder (less than 200 mesh). This is traditionally done with an agate mortar and pestle to ensure the particles are smaller than the wavelength of the IR light, which prevents scattering.

Ensuring Proper Pressure and Vacuum

When pressing the pellet, it is essential to use a vacuum pump to remove trapped air and moisture from the KBr powder. Air pockets will cause the pellet to appear cloudy and will significantly increase light scattering.

Applying sufficient pressure (typically several tons) is what fuses the KBr particles into a coherent, transparent disc. An easily broken or opaque pellet is often a sign of inadequate pressure or a poor vacuum during pressing.

How to Apply This to Your Analysis

Your preparation strategy should be guided by your analytical goals and the quality of the spectrum you need.

- If your primary focus is obtaining a high-quality, quantitative spectrum: You must use dry, spectroscopic-grade KBr and ensure meticulous, consistent grinding to a uniform particle size.

- If your primary focus is avoiding sample contamination: Always run a background measurement using a "blank" pellet made from your batch of pure KBr to digitally subtract any residual water or other impurity signals.

- If your primary focus is troubleshooting a cloudy or broken pellet: The most likely culprits are insufficient grinding, moisture contamination, or inadequate pressure and vacuum during the pressing process.

Ultimately, mastering the KBr pellet technique is a foundational skill for achieving reliable and accurate infrared analysis of solid materials.

Summary Table:

| Key Property | Why It Matters for FTIR Pellets |

|---|---|

| Infrared Transparency | Has no absorption bands in the mid-IR range (4000-400 cm⁻¹), ensuring a clean spectrum of your sample alone. |

| Plasticity Under Pressure | Fuses into a solid, transparent disc when pressed, creating a stable window for the IR beam. |

| Sample Dilution | Allows for a uniform 1:100 sample-to-matrix ratio, preventing signal saturation and enabling quantitative analysis. |

Achieve Reliable and Accurate Solid Sample Analysis with KINTEK

Mastering the KBr pellet technique is essential for high-quality FTIR results. Proper preparation requires the right materials and equipment to avoid common pitfalls like moisture contamination and poor pellet clarity.

KINTEK specializes in supplying the high-purity spectroscopic-grade KBr and robust pellet presses your laboratory needs for consistent success. Our products are designed to help you create perfect pellets, ensuring clear baselines and unambiguous spectra for your solid samples.

Ready to enhance your FTIR analysis? Contact our experts today to find the ideal KBr and pressing equipment for your specific laboratory requirements.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- kbr pellet press 2t

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Automatic Laboratory Hydraulic Pellet Press Machine for Lab Use

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

People Also Ask

- Which metal is harder to melt? Tungsten Leads with the Highest Melting Point

- How does a rotavap work? A Guide to Gentle, Efficient Solvent Removal

- What are the advantages of sintering? Achieve Superior Material Properties and Cost-Effective Production

- What are the most efficient and environment-friendly refrigerant fluids used in Ultra Freezers? Choose Natural Hydrocarbons for a Greener Lab

- What are the limitations and disadvantages of powder metallurgy? Understanding the Trade-Offs for Your Application

- How does plasma sputtering work? Master Precision Thin-Film Deposition

- What role does a laboratory orbital shaker play in silane coupling? Enhance Self-Assembled Monolayer Uniformity

- What type of evaporation is used for removing flammable solvents? Safely Remove Flammable Solvents with Explosion-Proof Rotary Evaporators