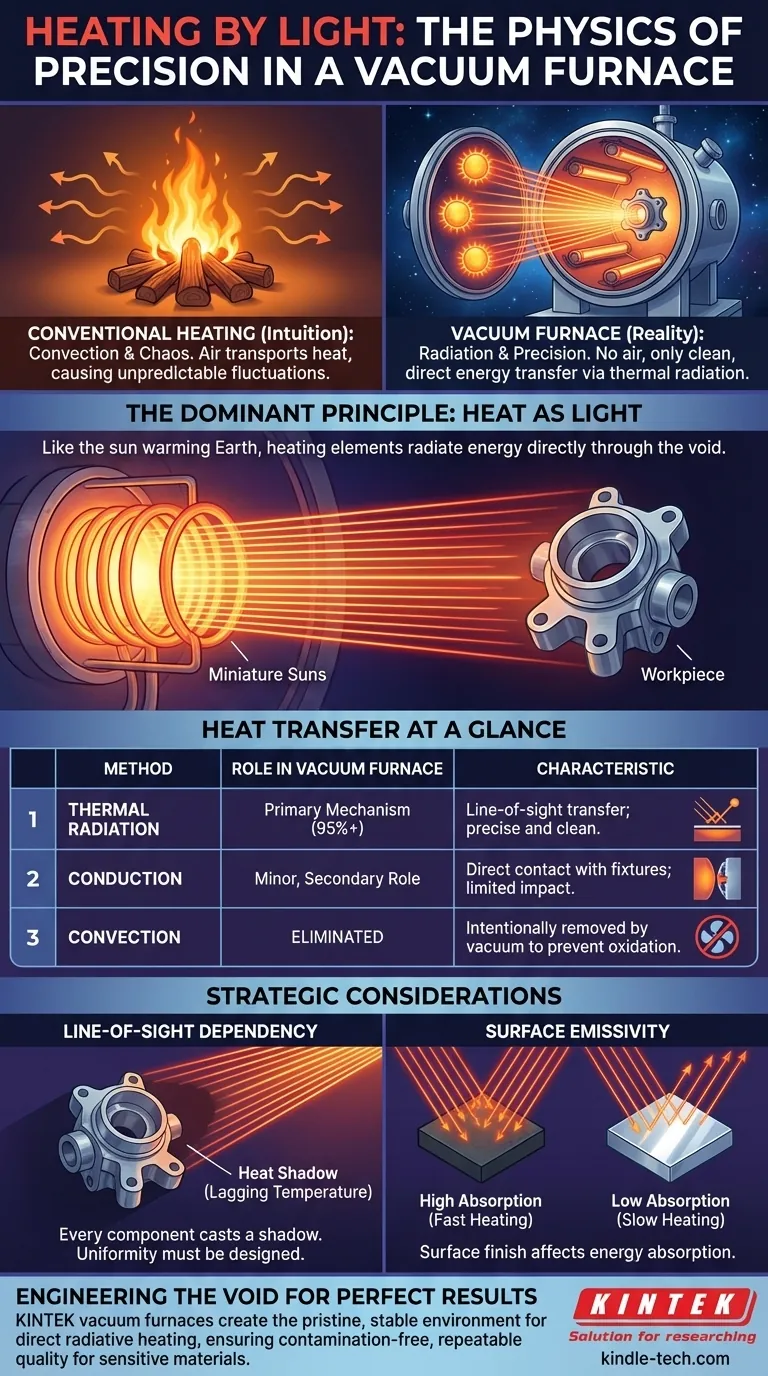

The Intuition We Must Unlearn

Think about the heat from a bonfire. You feel it on your face as waves of warmth, but you also see the chaotic dance of hot air rising. Our daily experience teaches us that heat travels through the air around us.

This intuition is the first thing we must discard when we enter the world of a vacuum furnace.

Inside that pristine, controlled chamber, the rules are different. By removing the air, we remove the medium for heat transfer we are most familiar with. We are left with a more fundamental, elegant, and powerful force: thermal radiation.

Heating a part in a vacuum isn't like baking in a conventional oven; it's like positioning a planet to receive light from its sun.

The Dominant Principle: Heat as Light

The sun warms the Earth across 93 million miles of empty space. It does so through thermal radiation—a stream of electromagnetic energy. A vacuum furnace operates on the exact same principle, just on a much smaller scale.

Radiation in the Void

Everything with a temperature above absolute zero emits thermal energy. The hotter an object gets, the more energy it radiates.

Inside a vacuum furnace, heating elements made of graphite or molybdenum act as miniature suns. When energized, they reach extreme temperatures and flood the chamber with infrared energy. This energy travels in straight lines through the vacuum until it strikes the workpiece, where it's absorbed and converted into heat.

There are no hot spots from swirling air currents, no unpredictable fluctuations. There is only the clean, direct transfer of energy from the source to the target.

The Psychology of "Line-of-Sight"

This "line-of-sight" dependency changes how we must think about the process. The challenge is no longer about circulating heat but about managing light.

You have to think like a lighting designer, not just an engineer. Every component loaded into the furnace casts a "heat shadow." Any surface hidden from the heating elements will lag in temperature, just as the side of a building opposite the sun remains cool.

This requires a deliberate and strategic approach to loading parts, ensuring every critical surface has a direct view of the energy source. Uniformity is not a given; it is engineered.

The Supporting Role and the Deliberate Absence

While radiation dominates, it isn't the only actor. Conduction plays a small part, while convection is intentionally banished.

Conduction: The Point of Contact

The workpiece rests on a fixture or hearth. At these direct points of contact, heat conducts from the hot fixture into the part.

However, the surface area involved in conduction is typically minuscule compared to the total surface area being bathed in radiation. It's an anchor point for heat, but it's not the main event.

Why Convection is the Enemy

In a standard furnace, fans circulate hot air (convection) to distribute heat. In a vacuum furnace, removing the air is the entire point.

Air contains oxygen and other reactive gases. At high temperatures, these gases are aggressive agents of contamination, causing oxidation and discoloration that can compromise the integrity of sensitive materials.

By creating a vacuum, we eliminate the medium for convection. This act achieves two critical goals:

- It protects the part, ensuring a perfectly clean, bright finish.

- It stabilizes the process, creating a predictable environment free from the chaos of turbulent air.

The Strategic Trade-Offs of a Radiation-First World

This reliance on radiation creates a unique set of operational considerations. Mastering them is the key to unlocking the technology's full potential.

-

Heating Uniformity is Designed: You cannot simply place parts in the furnace and expect even heating. Uniformity is achieved through careful arrangement and intelligent fixturing, ensuring all surfaces get their share of radiant energy.

-

The Surface is the Interface: A material's ability to absorb radiant energy is called emissivity. A dull, dark surface absorbs heat eagerly, while a shiny, reflective surface deflects it. This means two identical parts with different surface finishes will behave differently, a factor that must be accounted for in any precision process.

-

A Different Temperature Curve: At lower temperatures, radiation is less efficient than convection, sometimes leading to longer initial ramp-up times. But as temperatures soar, radiation becomes an exponentially more powerful and rapid method of heat transfer.

Heat Transfer at a Glance

| Heat Transfer Method | Role in Vacuum Furnace | Key Characteristic |

|---|---|---|

| Thermal Radiation | Primary Mechanism (95%+) | Line-of-sight transfer via electromagnetic waves; precise and clean. |

| Conduction | Minor, Secondary Role | Heat transfer through direct contact with fixtures; limited impact. |

| Convection | Eliminated | Intentionally removed by the vacuum to prevent oxidation and contamination. |

Engineering the Void for Perfect Results

Understanding these physics is the first step; having the right equipment is the second. The principles of radiative heat transfer demand an environment of extreme stability and control.

KINTEK's vacuum furnaces are engineered to provide exactly that. They create the pristine, stable void necessary to leverage the power of direct radiative heating, delivering the contamination-free results and process repeatability essential for advanced laboratory and industrial applications. By mastering the flow of heat as light, we enable you to achieve unparalleled quality in your most sensitive materials.

To harness the power of this precise and clean heating method for your most critical applications, Contact Our Experts.

Visual Guide

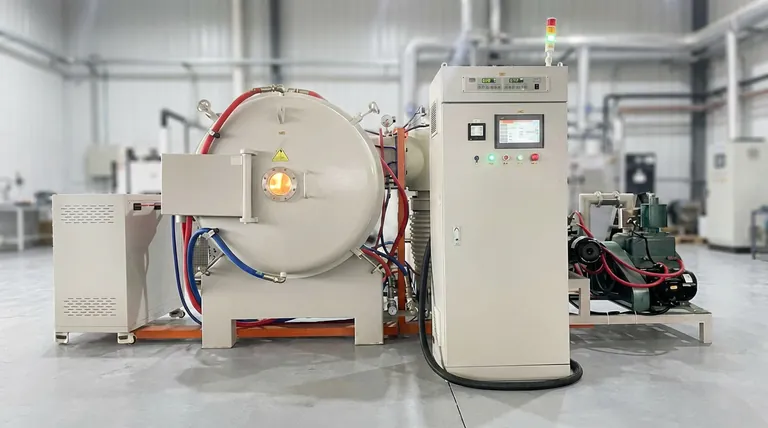

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

Related Articles

- Your Vacuum Furnace Hits the Right Temperature, But Your Process Still Fails. Here’s Why.

- The Symphony of Silence: Molybdenum and the Architecture of the Vacuum Hot Zone

- Why Your Brazed Joints Are Inconsistent—And the Fix Isn't in the Furnace

- Molybdenum Vacuum Furnace: High-Temperature Sintering and Heat Treatment

- Your Furnace Hit the Right Temperature. So Why Are Your Parts Failing?