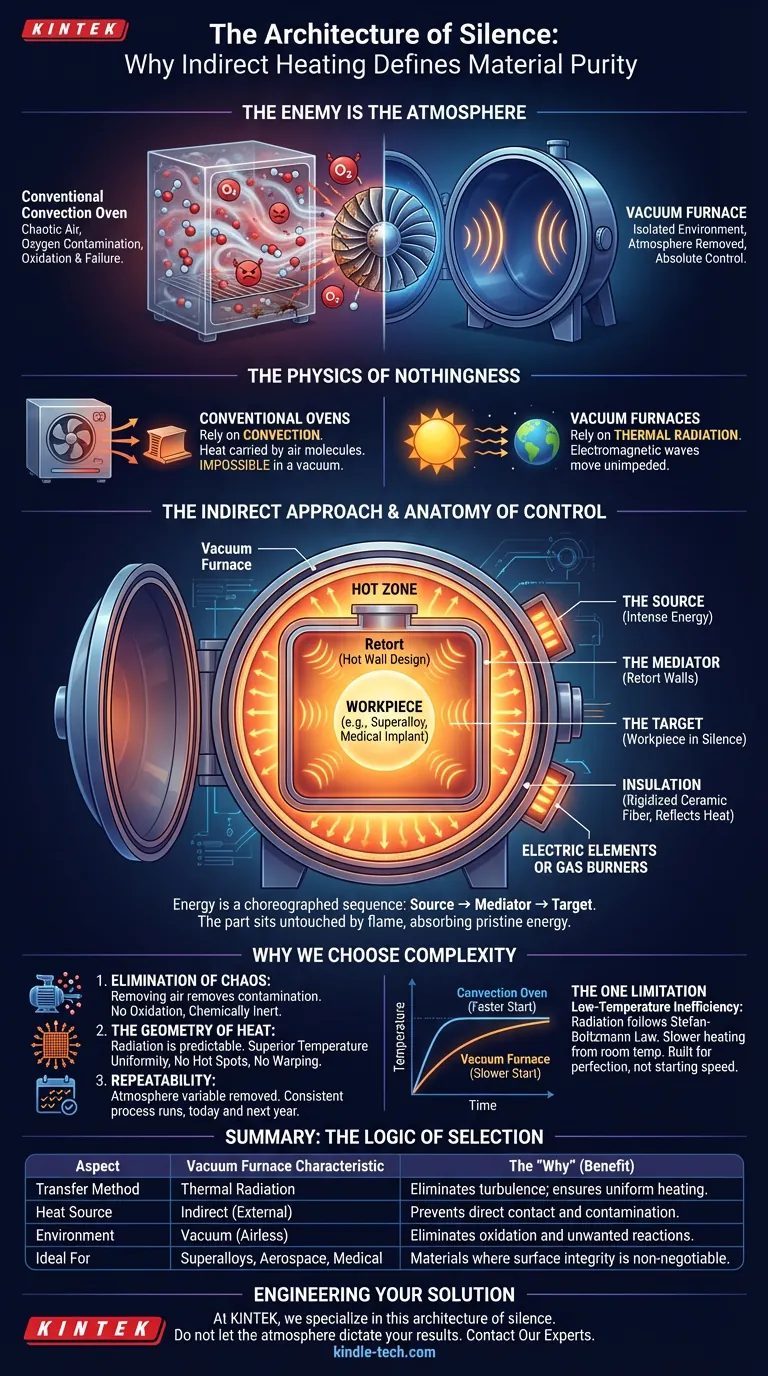

The Enemy is the Atmosphere

In the world of high-performance materials, the air we breathe is a chaotic variable.

For a superalloy turbine blade or a medical implant, oxygen is not life; it is corruption. A single microscopic interaction with the atmosphere during heat treatment can lead to oxidation, decarburization, or structural failure.

The solution is not just to heat the material. It is to isolate it.

This is the defining philosophy of the vacuum furnace. Unlike standard industrial ovens that rely on the brute force of hot air, a vacuum furnace operates on a principle of elegant separation. It is an exercise in "indirect heating."

The heat source never touches the workpiece. The atmosphere is removed. What remains is a system designed for absolute control.

The Physics of Nothingness

To understand how a vacuum furnace heats, you must first forget how your kitchen oven works.

Conventional ovens rely on convection. They heat the air, and fans blow that air around to transfer energy. But in a vacuum, there is no air. There are no molecules to carry the thermal load. Convection is impossible.

Instead, vacuum furnaces rely on thermal radiation.

It is the same physics that allows the sun to warm the earth through the vacuum of space. The energy travels as electromagnetic waves, moving unimpeded until it strikes a surface.

The Indirect Approach

In this system, the transfer of energy is a carefully choreographed sequence:

- The Source: Electric elements or gas burners generate intense energy.

- The Mediator: These heaters warm the internal chamber walls or a sealed container known as a retort.

- The Target: The superheated surfaces radiate energy inward, bathing the workpiece in uniform heat from all sides.

The part sits in silence, untouched by flame or heating element, absorbing energy in a pristine environment.

The Anatomy of Control

A vacuum furnace is an integrated system where every component serves the god of Purity. It is engineered to manage the flow of radiation while withstanding extreme stress.

The Hot Zone

This is the heart of the furnace. It is an insulated interior designed to hold temperature stability. It must heat rapidly, but more importantly, it must cool rapidly to lock in material properties.

The Retort (Hot Wall Design)

In "hot wall" designs, the separation is physical. The parts are placed inside a vacuum-tight vessel called a retort. The heaters sit outside this vessel. They heat the wall of the retort, which then radiates heat to the parts inside.

It is a box within a box. The outer box handles the combustion; the inner box preserves the vacuum.

The Insulation

To contain this radiant energy, advanced insulation—often rigidized ceramic fiber—is used. It has low thermal mass, meaning it doesn't soak up heat like a sponge. Instead, it reflects it back toward the workload.

Why We Choose Complexity

Engineering a vacuum system is difficult. It requires heavy pumps, precise seals, and expensive materials. Why do we accept this complexity?

Because the trade-offs of the "easy way" are unacceptable for mission-critical parts.

1. The Elimination of Chaos

By removing the air, we remove the chemistry of contamination. There is no oxygen to rust the metal. There is no carbon to alter the surface hardness unexpectedly. The environment is chemically inert.

2. The Geometry of Heat

In a convection oven, air currents create turbulence. You get hot spots and cold shadows.

In a vacuum, radiation is geometric and predictable. It provides superior temperature uniformity. This is vital for complex shapes where uneven heating would cause warping or internal stress.

3. Repeatability

When you remove the variable of the atmosphere, you get consistency. A process run today will look exactly like a process run next year.

The One Limitation

There is no such thing as a perfect system, only the right system for the job.

The reliance on radiation comes with a physics-based constraint: Low-temperature inefficiency.

Radiation follows the Stefan-Boltzmann law, which dictates that heat transfer efficiency increases drastically as temperature rises. Consequently, heating a part from room temperature to 600°F in a vacuum can be slower than in a convection oven.

The vacuum furnace is not built for speed at the starting line. It is built for perfection at the finish line.

Summary: The Logic of Selection

Deciding to use a vacuum furnace is rarely a question of cost; it is a question of consequence.

If a part fails, what happens? If the answer involves a plane engine shutting down or a medical device corroding, the vacuum furnace is the only logical choice.

| Aspect | Vacuum Furnace Characteristic | The "Why" (Benefit) |

|---|---|---|

| Transfer Method | Thermal Radiation | Eliminates turbulence; ensures uniform heating. |

| Heat Source | Indirect (External to workload) | Prevents direct contact and contamination. |

| Environment | Vacuum (Airless) | Eliminates oxidation and unwanted reactions. |

| Ideal For | Superalloys, Aerospace, Medical | Materials where surface integrity is non-negotiable. |

Engineering Your Solution

Understanding how a vacuum furnace heats is understanding how to deliver reliability in an unreliable world. It is about creating a sanctuary for your materials where the laws of thermodynamics work in your favor, without the interference of the atmosphere.

At KINTEK, we specialize in this architecture of silence.

We provide the high-performance lab equipment and consumables necessary for these precise operations. Whether you are brazing complex geometries or treating aerospace alloys, our solutions are designed to maintain the strict environmental controls your science demands.

Do not let the atmosphere dictate your results.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Graphite Vacuum Furnace IGBT Experimental Graphitization Furnace

Related Articles

- The Architecture of Emptiness: Achieving Metallurgical Perfection in a Vacuum

- The Engineering of Nothingness: Why Vacuum Furnaces Define Material Integrity

- The Hidden Variable: Why Your Vacuum Furnace Results Are Inconsistent, and How to Fix Them for Good

- Why Your High-Temperature Processes Fail: The Hidden Enemy in Your Vacuum Furnace

- Your Vacuum Furnace Hits the Right Temperature, But Your Process Still Fails. Here’s Why.