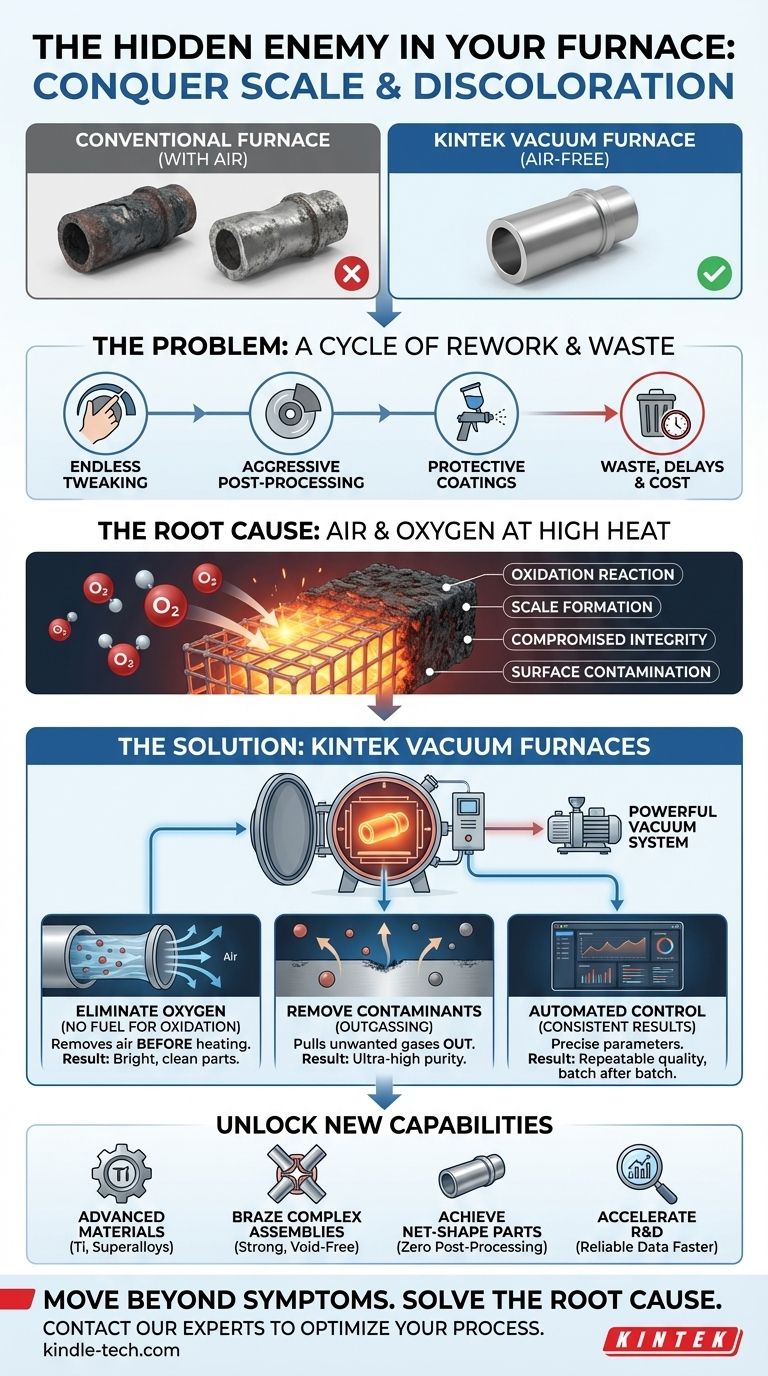

You pull a critical component from the furnace. It was supposed to be perfect—hardened, precise, and ready for integration. Instead, it’s covered in a dark, flaky layer of scale. The dimensions are off, the surface finish is ruined, and its structural integrity is now questionable. It’s another failed batch, another delay, and another frustrating setback that you can’t seem to pin down.

Trapped in a Cycle of Rework and Waste?

If this scenario feels familiar, you are not alone. Across countless labs and manufacturing floors, teams struggle with the same perplexing issue: inconsistent results from their thermal processing. To combat this, they often get caught in a costly and inefficient loop:

- Endless Tweaking: You adjust temperatures by a few degrees, extend or shorten soak times, and meticulously document every parameter, hoping to find the “magic formula.” Yet, the results remain unpredictable.

- Aggressive Post-Processing: Teams spend hours—or even days—grinding, sandblasting, or using harsh chemical baths to remove the unwanted oxidation and scale, only to risk damaging the part's precise geometry in the process.

- Trying Protective Coatings: You experiment with various coatings or foils to shield the material, adding extra steps, costs, and potential new sources of contamination.

This isn't just a technical headache; it's a direct drain on your business. Every failed batch leads to wasted material and energy. Every hour spent on rework is an hour not spent on innovation or production. Most importantly, unreliable part quality can lead to product failures, jeopardizing your reputation and bottom line.

The Real Culprit Isn't the Heat—It's the Air

Here is the turning point: The problem isn't that you're using the wrong temperature or time. The problem is the environment you're heating in.

At high temperatures, materials like steel, titanium, and other alloys don't just get hot; they become highly reactive. The oxygen present in a conventional furnace atmosphere—even in trace amounts—aggressively attacks the hot material surface. This chemical reaction is called oxidation, and it's the root cause of your problems:

- Scale and Discoloration: That flaky, dark layer is simply metal oxide. It’s the physical evidence of your part being chemically altered.

- Compromised Integrity: Oxidation can deplete key alloying elements from the surface, changing its metallurgical properties and making it weaker or more brittle than intended.

- Surface Contamination: The air itself introduces contaminants that get baked into the material, compromising its purity.

This is why the common "solutions" are doomed to fail. Grinding and blasting are just cleaning up the damage after it’s already been done. Tweaking the temperature is like trying to adjust the speed of a chemical reaction you can’t see. You are fighting a chemistry problem, not just a heating problem.

The Solution: Taking Control of the Environment

If the presence of air is the fundamental cause of the problem, then the only true solution is to remove it entirely. You need a tool that doesn't just generate heat, but creates a pristine environment where unwanted chemical reactions simply cannot happen.

This is the exact principle behind a vacuum furnace. It's not just a "better" furnace; it's a completely different approach to thermal processing, one that addresses the root cause of oxidation head-on.

KINTEK's Vacuum Furnaces: Engineered for Purity and Precision

A KINTEK vacuum furnace is a system designed from the ground up to give you total environmental control. It systematically eliminates the variables that cause failure in conventional furnaces.

-

The Root Cause: Air & Oxygen.

- The KINTEK Solution: A powerful, multi-stage vacuum system removes virtually all the air from a sealed chamber before heating begins. This starves the oxidation reaction of its fuel (oxygen), resulting in bright, clean, scale-free parts every time.

-

The Root Cause: Surface Contaminants.

- The KINTEK Solution: The vacuum doesn't just prevent new contaminants from entering; it actively pulls existing impurities and volatile gases out of the material itself—a process called outgassing. This is critical for achieving the ultra-high purity required for medical implants, aerospace components, and sensitive electronics.

-

The Root Cause: Inconsistent Results.

- The KINTEK Solution: With a fully automated control system, every parameter—from the vacuum level to the precise heating ramp and rapid gas quench—is perfectly managed and repeatable. You get the same exact metallurgical properties batch after batch, year after year.

Beyond a Perfect Finish: Unlocking New Capabilities

When you stop wasting resources fighting surface contamination, you can focus on what truly matters: innovation and performance. Eliminating this chronic problem doesn't just save you money on rework; it unlocks a new level of potential for your laboratory or production line.

With the pristine environment of a vacuum furnace, you can now:

- Work with Advanced Materials: Confidently process highly sensitive materials like titanium, superalloys, and refractory metals without fear of contamination.

- Braise Complex Assemblies: Create strong, clean, and void-free joints in complex assemblies that are impossible to achieve in a conventional atmosphere.

- Achieve Net-Shape Parts: Produce components so clean and precise that they require zero post-processing, dramatically shortening your production cycle.

- Accelerate R&D: Get reliable, repeatable data from your material tests, allowing you to validate new designs and alloys faster than ever before.

Solving this persistent challenge isn't just about getting a shinier part; it's about making your entire operation more predictable, efficient, and capable of tackling next-generation engineering problems. If you're ready to move beyond treating symptoms and finally solve the root cause of your thermal processing issues, our team is here to help. We can analyze your specific materials and process goals to determine the ideal solution for your application.

Let's discuss how to permanently eliminate oxidation and unlock the full potential of your materials. Contact Our Experts.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Molybdenum Vacuum Heat Treat Furnace

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

Related Articles

- Unlocking the Potential: Vacuum Levitation Induction Melting Furnace Explained

- Vacuum Melting Furnace: A Comprehensive Guide to Vacuum Induction Melting

- Exploring Tungsten Vacuum Furnaces: Operation, Applications, and Advantages

- Vacuum Induction Melting Furnace vs Arc Melting Furnace: Choosing the Right Equipment for Your Process

- Melting process and maintenance of vacuum induction melting furnace