The Psychology of a Choice

Every critical piece of laboratory or industrial equipment represents a commitment. When choosing a vacuum furnace, you aren't just buying a machine that heats things in a vacuum; you're casting a vote for your future.

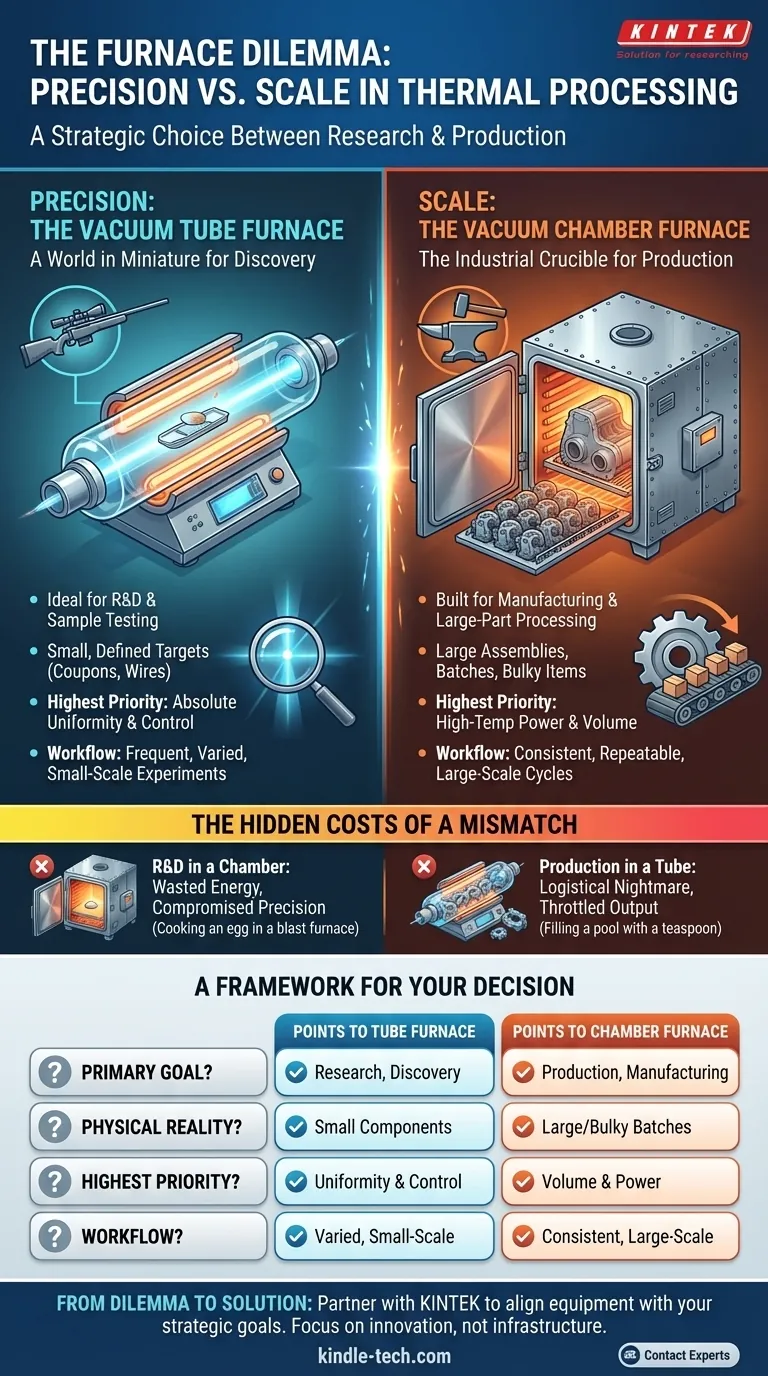

Are you in the business of discovery, meticulously testing the absolute limits of a new material on a small scale? Or are you in the business of production, transforming that discovery into a reliable, large-scale process?

This isn't a simple technical decision. It's a strategic one, and the choice between a vacuum tube furnace and a vacuum chamber furnace lies at its heart. It's a fundamental trade-off between precision and scale.

The Anatomy of the Two Worlds

The physical design of each furnace dictates its destiny. Understanding this is key to aligning the tool with the task.

The Tube Furnace: A World in Miniature

Imagine a ceramic or quartz tube, perfectly uniform, holding a single, precious sample. Heating elements surround this self-contained world, delivering exceptionally precise and uniform temperature.

This is the domain of the vacuum tube furnace. It is a sniper rifle: built for accuracy over a small, well-defined target. It's the essential tool for materials science research, annealing delicate electronic components, and any process where exactness is more valuable than volume.

The Chamber Furnace: The Industrial Crucible

Now, imagine a large steel vessel—a cold wall chamber with insulation and heating elements situated inside. Its purpose is not to study a single grain of sand, but to move the entire beach.

This is the vacuum chamber furnace. It is the workhorse of industry, designed for size and high-temperature power. This is where you perform vacuum brazing on complex aerospace assemblies, sinter batches of production parts, or heat-treat large components made of reactive metals like titanium.

The Hidden Costs of a Mismatch

Choosing the wrong furnace is more than an inconvenience; it's a systemic bottleneck that introduces frustration and risk.

-

Using a chamber furnace for R&D: It's like trying to cook a single egg in an industrial blast furnace. You fight for temperature uniformity across a vast, empty space, wasting energy and potentially compromising the precision your research demands. The machine's scale becomes a liability.

-

Using a tube furnace for production: It's like trying to fill a swimming pool with a teaspoon. You face a logistical nightmare of running countless small batches, inviting inconsistency, and creating a ceiling on your output. Your ambition is throttled by your equipment.

The true cost isn't just the price of the machine, but the friction it creates against your primary goal.

A Framework for Your Decision

To navigate this choice, don't start with a spec sheet. Start with your objective. The right furnace is the one that removes friction between your idea and its execution.

| Guiding Question | Points Toward a Tube Furnace | Points Toward a Chamber Furnace |

|---|---|---|

| What is your primary goal? | Research, sample testing, discovery. | Production, manufacturing, large-part processing. |

| What is the physical reality? | Small coupons, wires, powders, tiny components. | Large assemblies, batches of parts, bulky items. |

| What is your highest priority? | Absolute temperature uniformity and control. | High-temperature capability and processing volume. |

| What does your workflow look like? | Frequent, varied, small-scale experiments. | Consistent, repeatable, large-scale industrial cycles. |

This framework shifts the focus from "what can the furnace do?" to "what do we need to achieve?"

From Dilemma to Solution

Making the right choice between a tube and chamber furnace is a foundational decision that impacts your efficiency, scalability, and ultimate success. It requires a partner who understands the deep technical trade-offs and, more importantly, your strategic goals.

At KINTEK, we specialize in providing laboratory and industrial equipment that aligns perfectly with your work. We see the furnace not as a standalone product, but as a critical component of your process. Our expertise lies in helping you navigate this decision so you can focus on your innovation, not your infrastructure.

Let us help you translate your requirements into the right thermal processing solution. Contact Our Experts

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

Related Articles

- Your Vacuum Furnace Hits the Right Temperature, But Your Process Still Fails. Here’s Why.

- Mastering Vacuum Furnace Brazing: Techniques, Applications, and Advantages

- The Art of the Void: When Precision Matters More Than Power

- Why Your Brazed Joints Fail: The Truth About Furnace Temperature and How to Master It

- Vacuum Induction Furnace Fault Inspection: Essential Procedures and Solutions