You’ve spent days, maybe weeks, machining a component to exacting specifications. Every dimension is perfect. You place it in the furnace for its final heat treatment, confident in your process. But when you open the door, your heart sinks. The once-gleaming part is now covered in a dark, flaky scale. The surface is ruined, the dimensions are off, and all that meticulous work has been undone in the final step.

If this scenario sounds painfully familiar, you are not alone.

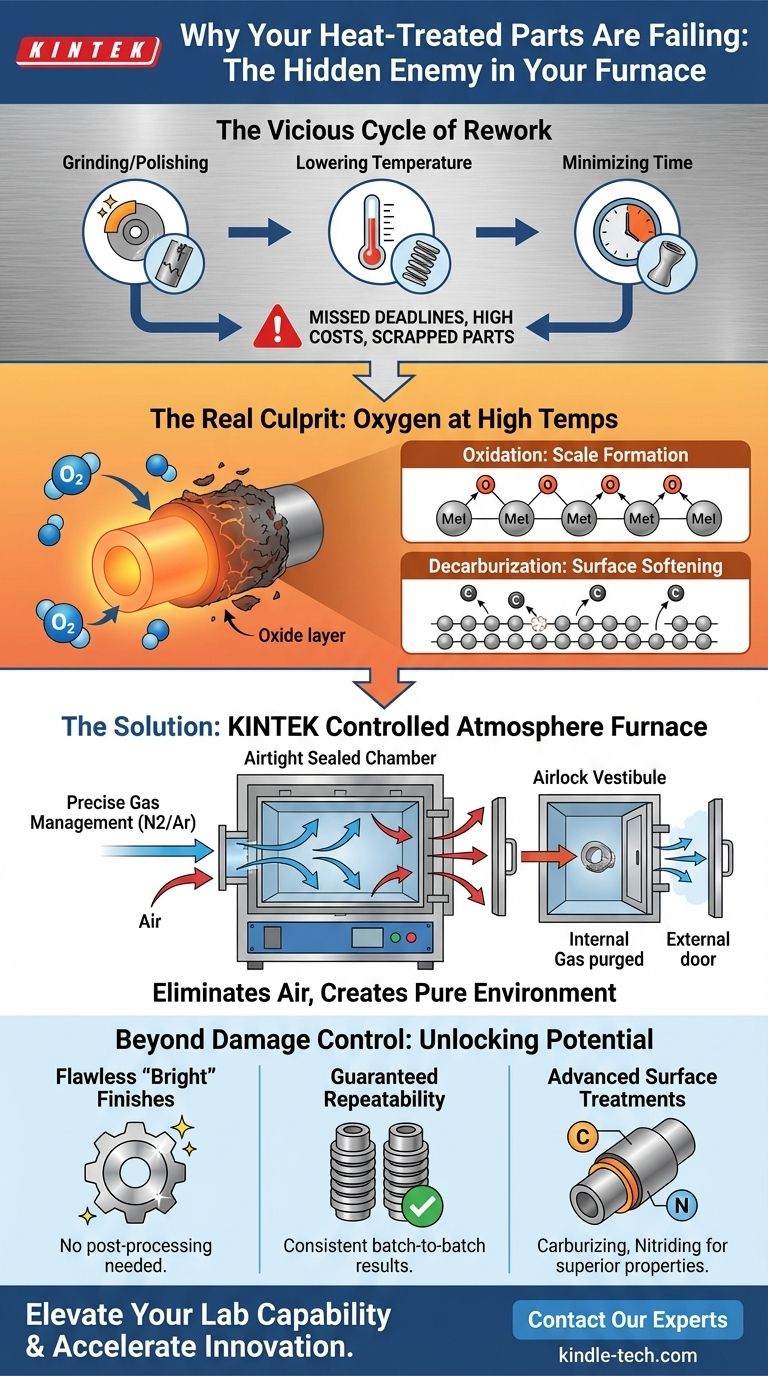

The Vicious Cycle of Rework: Why "Good Enough" Isn't Working

For laboratories and R&D teams, this is a recurring nightmare. The immediate response is often a series of frustrating compromises.

You might try:

- Grinding or polishing the scale off, but this adds a costly post-processing step and often ruins the part's precise dimensions and surface finish.

- Lowering the temperature, but this fails to achieve the required hardness or metallurgical properties.

- Minimizing time in the furnace, but this leads to inconsistent and incomplete treatment.

These are not solutions; they are patches. Each attempt is a gamble, and the results are rarely repeatable. This inconsistency has significant business consequences: project deadlines are missed, material costs skyrocket due to scrapped parts, and the reliability of your final product is compromised. You're trapped in a cycle of rework, constantly battling symptoms without ever solving the core problem.

The Real Culprit Isn't the Heat—It's the Air

Here is the turning point in understanding this issue: The problem is not the heat itself. It's the environment in which you are heating.

A standard furnace operates in ambient air. At room temperature, air is harmless. But at high temperatures, it transforms into an aggressive chemical agent. The oxygen within the air viciously attacks the surface of your material. This triggers two destructive reactions:

- Oxidation: Oxygen combines with the metal to form a layer of scale (oxide). This is the flaky, discolored coating that ruins your surface finish and dimensional accuracy.

- Decarburization: For steels, oxygen reacts with and strips carbon from the surface, making it softer and weaker—the exact opposite of what most heat treatments aim to achieve.

The "common solutions" mentioned earlier are doomed to fail because they don't address this fundamental chemical attack. You're trying to perform a delicate operation in a contaminated, hostile environment. It's like trying to perform sterile surgery in a dust storm. No matter how skilled you are, the environment will sabotage your results.

From Fighting Symptoms to Curing the Disease: The Right Tool

To get clean, consistent, and reliable results, you must stop fighting the symptoms of oxidation and instead eliminate the cause: the air itself.

This requires a tool designed not just to heat, but to create a perfectly controlled, pure environment. This is the entire principle behind a controlled atmosphere furnace. It is not just an incremental improvement over a standard furnace; it is a fundamentally different approach, engineered from the ground up to solve the problem of atmospheric contamination.

This is precisely why KINTEK’s controlled atmosphere furnaces are so effective. They are the direct, engineered answer to the problem of air contamination:

- An Airtight, Sealed Chamber: The first and most critical feature is its hermetically sealed body. This acts as an impenetrable fortress, preventing destructive outside air from leaking in and contaminating your process.

- Precise Gas Management: The system actively purges all the air and replaces it with a specific, inert gas like nitrogen or argon. This protective atmosphere is completely non-reactive, ensuring your part's surface remains pristine and unaltered from start to finish.

- Airlock Vestibule: To load or unload parts without poisoning the entire furnace with air, a front "airlock" chamber is used. Your part enters the vestibule, the air is purged, it's filled with the protective gas, and only then does the door to the main heating chamber open.

A KINTEK furnace isn't just a box that gets hot. It is a complete environmental control system, designed with a deep understanding of the underlying chemistry that causes parts to fail.

Beyond Damage Control: Unlocking Advanced Material Engineering

Once you are no longer just trying to prevent damage, a world of new possibilities opens up. A controlled atmosphere furnace transforms from a defensive tool into a powerful instrument for proactive surface engineering.

With the threat of oxidation completely removed, you can now:

- Achieve Flawless "Bright" Finishes: Produce parts that come out of the furnace as clean and bright as when they went in, eliminating the need for costly and damaging post-processing.

- Guarantee Repeatability: Because the chemical environment is identical for every single run, you achieve unmatched consistency from batch to batch, ensuring higher qualification rates and more reliable data for R&D.

- Perform Advanced Surface Treatments: You can move beyond simple protection and intentionally alter a material's surface. By introducing specific active gases, you can perform processes like carburizing (adding carbon) or nitriding (adding nitrogen) to create an incredibly hard, wear-resistant surface layer on a component while maintaining a tougher, more ductile core. This level of material science is simply impossible in a standard furnace.

Solving this old, frustrating problem doesn't just save you time and money on rework. It elevates the very capability of your lab, enabling you to develop more advanced materials, improve product performance, and accelerate your innovation timeline.

Your projects demand precision from start to finish. Don't let the final step be a source of failure. If you're ready to move beyond fighting symptoms and start achieving perfect, repeatable results, let's discuss how the right atmospheric control can transform your work. Contact Our Experts.

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Brazing Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

Related Articles

- Molybdenum Vacuum Furnace: High-Temperature Sintering and Advanced Applications

- The Art of Absence: Why Advanced Materials Demand Vacuum Furnaces

- The Symphony of Silence: Molybdenum and the Architecture of the Vacuum Hot Zone

- Why Your Brazed Joints Are Inconsistent—And the Fix Isn't in the Furnace

- Your Vacuum Furnace Hits the Right Temperature, But Your Process Still Fails. Here’s Why.