It’s a scenario familiar to many materials scientists and lab managers. After days of meticulous preparation, you open your vacuum furnace, anticipating a perfectly treated component. Instead of the strong, refined part you expected, you find a piece of expensive scrap—warped, brittle, or with a completely flawed microstructure. You followed the temperature guidelines, so what went wrong?

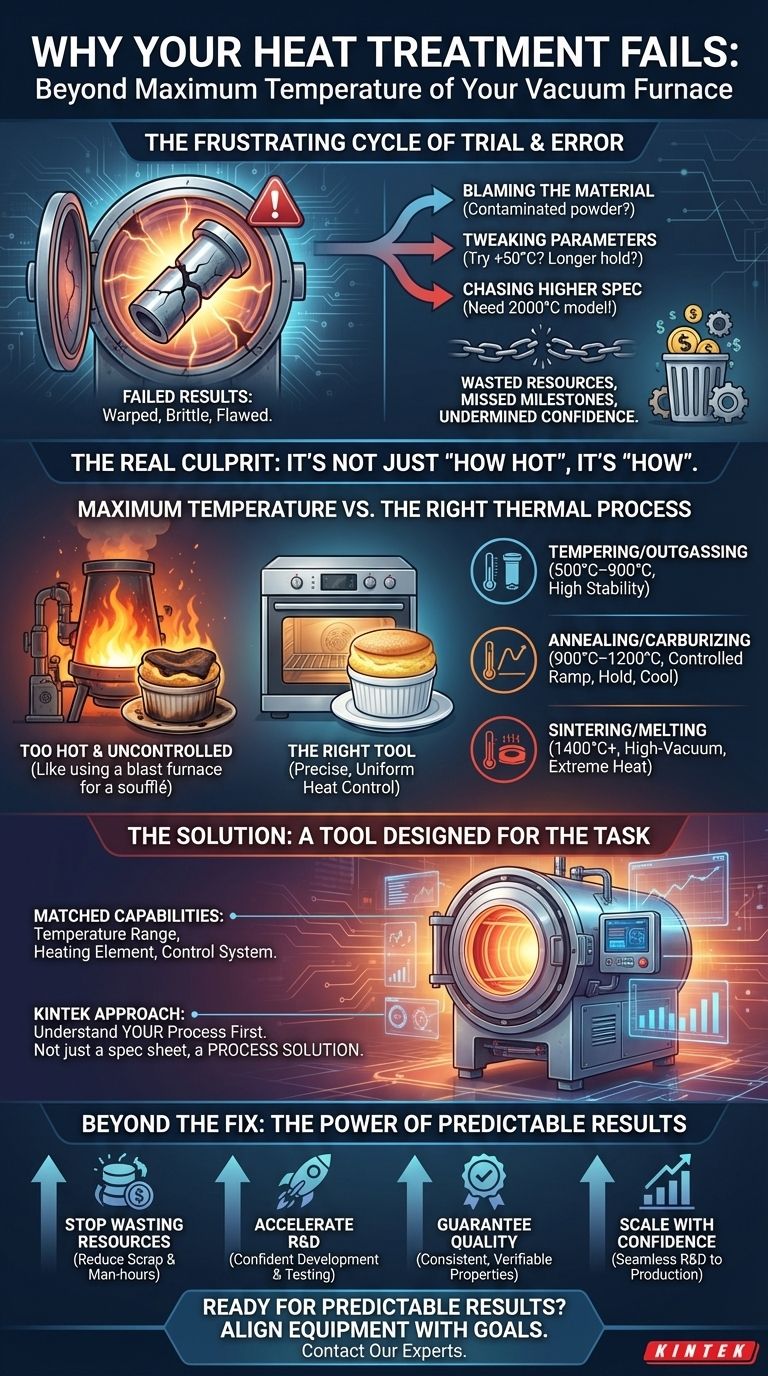

The Frustrating Cycle of Trial and Error

If this scene feels personal, you are not alone. Across countless advanced laboratories, teams are stuck in a frustrating loop of guesswork when their thermal processes fail. The common reactions are predictable:

- Blaming the Material: "Maybe this batch of alloy powder was contaminated."

- Tweaking the Parameters: "Let's try running it 50°C hotter next time," or "Maybe we held it at temperature for too long."

- Chasing a Higher Spec: "Our current furnace only reaches 1400°C. We must need a 2000°C model to get this right."

These are not just academic exercises; they have severe business consequences. Each failed run translates directly into wasted high-value materials, from custom alloys to advanced ceramics. It means missed R&D milestones that delay product launches and erode competitive advantage. Most importantly, it undermines confidence. How can you guarantee product quality when your most critical manufacturing step is unpredictable?

This cycle of failure continues because these "solutions" only address the symptoms, not the underlying cause.

The Real Culprit: It's Not Just 'How Hot,' It's 'How'

The turning point comes when you shift your core question from "How hot can my furnace get?" to "What thermal process does my material need?" A vacuum furnace is not just an oven; it's a precision instrument for executing a specific metallurgical recipe.

The fundamental mistake is assuming that a higher maximum temperature is always better. The truth is that different processes are activated by entirely different thermal profiles.

Maximum Temperature vs. The Right Thermal Process

Think of it like cooking. You wouldn't use a blast furnace designed for smelting iron to bake a delicate soufflé. Even though the blast furnace is "hotter," it lacks the precise, gentle, and uniform heat control required for the task. The same principle applies to materials science:

- Tempering or Outgassing: These processes require lower, sustained temperatures (e.g., 500°C - 900°C) with high stability to relieve internal stresses or remove trapped gases without altering the material's core structure. A furnace designed for extreme heat might struggle to maintain precise control in this lower range.

- Annealing or Carburizing: These rely on a carefully controlled ramp-up, a long hold at a precise mid-range temperature (e.g., 900°C - 1200°C), and often a specific cooling rate to achieve the desired grain structure and hardness.

- Sintering or Melting: These advanced applications truly require high temperatures (1400°C to over 2000°C) to fuse powdered metals or melt high-performance alloys.

The common "solutions" fail because they ignore this principle. Randomly tweaking the temperature is like guessing the baking time for a cake. And buying a furnace with excessive temperature capability for a low-temperature process is a costly mismatch of tool to task, often sacrificing the fine control you actually need.

The Solution: A Tool Designed for the Task, Not Just the Spec Sheet

To break this cycle of failure, you need a furnace whose capabilities—its temperature range, heating element material, and control system—are precisely matched to your application. This is where the right equipment, guided by expertise, becomes transformative.

A furnace is not just a commodity; it is the embodiment of a process solution. A truly effective furnace is designed with a deep understanding of these thermal principles.

- For annealing standard alloys, the ideal tool is a furnace that offers exceptional temperature uniformity and stability in the 500°C to 1400°C range, governed by a sophisticated PID or PLC controller.

- For sintering advanced ceramics, the solution is a specialized high-temperature furnace, likely with graphite heating elements and insulation, capable of reaching 2200°C while maintaining a clean, high-vacuum environment.

At KINTEK, we don't just sell lab equipment; we provide access to the right tools for the job. Our approach is built on understanding your process first. We help you navigate the specifications to find a furnace that delivers not just heat, but the precise, repeatable thermal control your application demands.

Beyond the Fix: The Power of Predictable Results

When you finally have the right tool for the job, everything changes. The nagging uncertainty that plagued your work disappears, replaced by the confidence that comes with predictability.

This is where true innovation begins. With a reliable and repeatable thermal process, you can:

- Stop Wasting Resources: Drastically reduce material scrap and wasted man-hours, freeing up your budget and your team for more valuable work.

- Accelerate R&D: Confidently develop new materials and push the boundaries of performance, knowing your equipment is a stable constant, not a frustrating variable.

- Guarantee Quality: Deliver components with consistent, verifiable properties every single time, building trust with your clients and stakeholders.

- Scale with Confidence: Seamlessly transition from a successful R&D process to pilot production, knowing the results are transferable.

Solving this old, frustrating problem doesn't just fix a technical issue; it unlocks your lab's full potential for discovery and growth.

Your work is too important for guesswork. If you're tired of unpredictable results and ready to implement a thermal process you can trust, it's time to align your equipment with your goals. Let our team help you move beyond the spec sheet and achieve the predictable, high-quality outcomes your work demands. Contact Our Experts.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

Related Articles

- The Hidden Variable: Why Your Vacuum Furnace Results Are Inconsistent, and How to Fix Them for Good

- The Architecture of Emptiness: Achieving Metallurgical Perfection in a Vacuum

- Why Your Heat-Treated Parts Fail: The Invisible Enemy in Your Furnace

- Beyond Heat: Mastering Material Purity in the Controlled Void of a Vacuum Furnace

- Why Your High-Temperature Processes Fail: The Hidden Enemy in Your Vacuum Furnace