Articles

Understanding the Isostatic Pressing Process: Origins, Types, and Applications

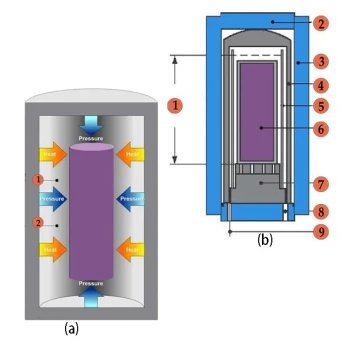

1 year agoThe isostatic pressing process was pioneered in the mid-1950s and has steadily grown from a research curiosity to a viable production tool. Many industries apply this technique for consolidation of powders or defect healing of castings.

Learn More

Warm Isostatic Pressing: An Advanced Manufacturing Technology

1 year agoWarm Isostatic Pressing (WIP) is a cutting-edge technology that enables isostatic pressing at a temperature that does not exceed the boiling point of the liquid medium. It is a variant of cold isostatic pressing (CIP) that includes a heating element.

Learn More

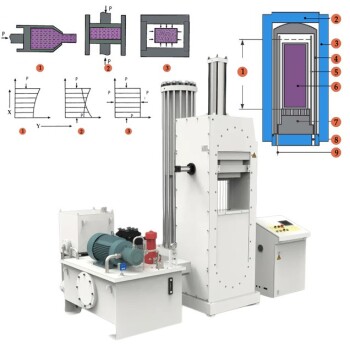

Understanding Cold Isostatic Pressing and Its Applications

1 year agoCold isostatic pressing (CIP) is a method of processing materials. It involves compacting powders by enclosing them in an elastomer mold and applying uniform liquid pressure to compress the mold. This results in a highly compact solid. Cold isostatic pressing is commonly used for plastics, graphite, powdered metallurgy, ceramics, sputtering targets, and other materials.

Learn More

Determining Optimal Pressure for XRF Pellet Pressing

1 year agoThe process of XRF pellet pressing involves applying pressure to a sample to create a solid pellet that can be analyzed by an X-ray fluorescence (XRF) spectrometer. Optimal pressure is crucial for achieving accurate and reliable results in XRF analysis.

Learn More

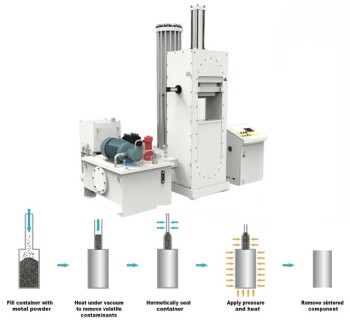

Understanding Isostatic Pressing in Powder Metallurgy

1 year agoIsostatic pressing is a powder processing technique that uses fluid pressure to compact the part. It involves placing metal powders in a flexible container, which acts as the mold for the part. Fluid pressure is then exerted over the entire outside surface of the container, causing it to press and form the powder into the desired geometry.

Learn More

Understanding Isostatic Pressing: Cold and Hot Techniques

1 year agoIsostatic pressing is a powder processing technique that uses fluid pressure to compact the part. It involves placing metal powders in a flexible container, which acts as a mold for the part. Fluid pressure is exerted over the entire outside surface of the container, causing the powder to be formed into the desired geometry. Unlike other processes that exert force on the powder through an axis, isostatic pressing applies pressure equally from all directions.

Learn More

Dilution Ratios for XRF Pelletising Finding the Optimal Balance

1 year agoXRF analysis is a powerful technique used by researchers and scientists to determine the elemental composition of various materials. One of the most crucial steps in XRF analysis is the preparation of samples for analysis, which often involves creating pellets from powdered samples.

Learn More

Understanding Cold Isostatic Pressing (CIP) and Its Advantages

1 year agoCold Isostatic Pressing (CIP) is a unique technique used in the manufacturing industry for compacting and shaping materials. It involves subjecting a material to uniform pressure from all directions, resulting in a highly dense and uniform product. CIP is particularly useful for machining and metal forming tools, as well as for large parts that don't require high precision.

Learn More

Understanding Isostatic Pressing: Process, Benefits, Limitations, and Applications

1 year agoIsostatic pressing is a manufacturing process that offers numerous benefits and applications in various industries. It involves subjecting a material to equal pressure from all directions to achieve uniform density and shape. This method is particularly advantageous compared to other production techniques.

Learn More

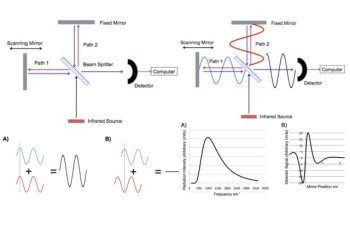

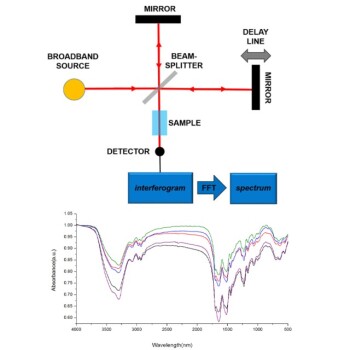

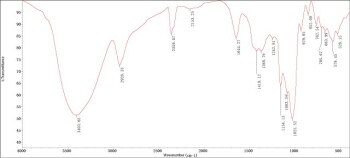

Everything You Need to Know About FTIR Pellet Press

1 year agoFourier Transform Infrared (FTIR) spectroscopy is a non-destructive analytical technique used to identify and quantify the chemical composition of a sample. FTIR pellet presses are used to prepare solid samples for FTIR analysis by compressing them into pellets.

Learn More

Understanding Cold Isostatic Pressing (CIP) and Hot Isostatic Pressing (HIP) in Powder Metallurgy

1 year agoCold Isostatic Pressing (CIP) and Hot Isostatic Pressing (HIP) are two powder metallurgy techniques used to produce dense and high-quality metal components.

Learn More

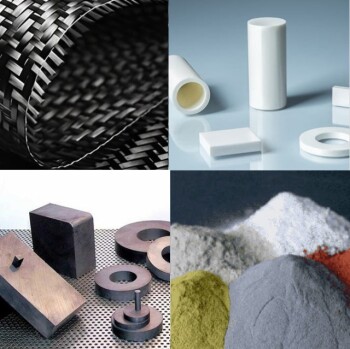

Exploring the Applications of Isostatic Pressing

1 year agoIsostatic pressing is a powder metallurgy technique that applies equal pressure from all directions to a compacted powder. There are two types of isostatic pressing: cold isostatic pressing (CIP) and hot isostatic pressing (HIP). CIP uses pressure at room temperature, while HIP applies heat and pressure to the powder.

Learn More

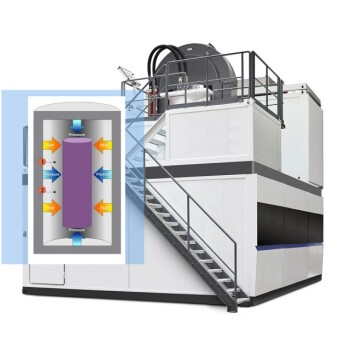

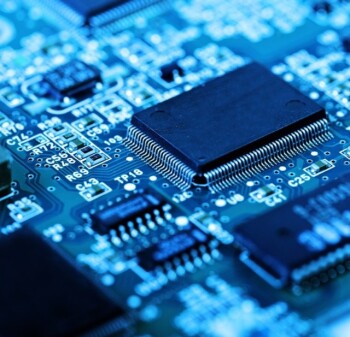

Understanding Warm Isostatic Press: An Essential Tool in Electronics Manufacture

1 year agoWarm Isostatic Press (WIP) equipment, also known as Warm Isostatic Laminator, is a cutting-edge technology that combines isostatic pressing with a heating element. It utilizes warm water or a similar medium to apply uniform pressure to powdered products from all directions. The process involves shaping and pressing the powder material using flexible materials as a jacket mold and hydraulic pressure as a pressure medium.

Learn More

FTIR Pellet Press The Game-Changer in Spectroscopy Analysis

1 year agoFourier Transform Infrared Spectroscopy (FTIR) is a widely used analytical technique in the field of chemistry and materials science. It is a non-destructive method that allows the identification and quantification of chemical compounds in a sample.

Learn More

Understanding the Warm Isostatic Pressing Technique

1 year agoWarm Isostatic Pressing (WIP) is a technique used in the manufacturing industry to form and press powder materials. It involves the use of a flexible material as the envelope die and hydraulic pressure as the medium to shape the material. Unlike traditional pressing methods, WIP utilizes a liquid medium that is heated and injected into a sealed pressing cylinder. This technique is particularly beneficial for materials with special temperature requirements or those that cannot be formed at room temperature.

Learn More

Understanding Cold Isostatic Pressing: Process, Comparisons, and Applications

1 year agoCold isostatic pressing (CIP) is a method of processing materials that involves compacting powders by enclosing them in an elastomer mold. The process is based on Pascal's law, which states that pressure applied in an enclosed fluid is transmitted in all directions throughout the fluid without any change in magnitude.

Learn More

FTIR Pellet Press The Ultimate Solution for Precise Sample Preparation

1 year agoFourier Transform Infrared (FTIR) spectroscopy is a powerful analytical technique that can be used to identify and quantify the chemical components of a sample. However, to obtain accurate and reliable results, it is crucial to prepare the sample appropriately.

Learn More

Understanding Cold Isostatic Pressing: Process, Advantages and Types

1 year agoCold Isostatic Pressing (CIP), also known as cold isostatic compaction, is a materials processing technique that involves subjecting a material to uniform pressure from all sides. This is achieved by immersing the material in a high-pressure fluid medium and applying hydraulic pressure. CIP is particularly effective for shaping and consolidating powdered materials, allowing for the creation of intricate shapes and achieving high green density.

Learn More

Understanding Cold Isostatic Pressing: Process, Advantages and Types

1 year agoCold Isostatic Pressing (CIP), also known as cold isostatic compaction, is a materials processing technique that involves subjecting a material to uniform pressure from all sides. This is achieved by immersing the material in a high-pressure fluid medium and applying hydraulic pressure.

Learn More

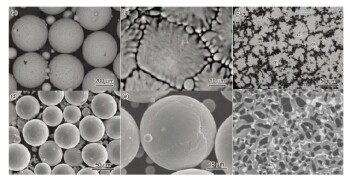

Hot Isostatic Pressing Achieving Optimal Microstructure Uniformity

1 year agoHot Isostatic Pressing(HIP ) is a technology used to densify materials at high temperatures and pressures. The process involves placing a material in a sealed container, which is then pressurized with an inert gas and heated to a high temperature.

Learn More

Technical Aspects of Cold Isostatic Pressing

1 year agoIsostatic pressing, is a process that involves compacting a dry or semi-dry powder in an elastomeric mold submerged in a pressurized liquid. One of the key advantages of isostatic compaction over cold pressing is the uniform pressure application.

Learn More

Hot & Cold Isostatic Pressing: Applications, Process, and Specifications

1 year agoHot Isostatic Pressing (HIP) is a manufacturing process that involves the simultaneous application of high temperature and pressure to metals and other materials. The purpose of HIP is to reduce the porosity of metals and increase the density of ceramic materials. This process improves the mechanical properties and workability of the materials.

Learn More

Hot Isostatic Pressing vs. Cold Isostatic Pressing

1 year agoIsostatic pressing is a manufacturing process used to produce high-density materials with improved mechanical properties. It operates by applying uniform pressure to the material from all directions to eliminate voids, cracks, and porosity.

Learn More

Understanding Isostatic Presses: Types, Processes, and Applications

1 year agoIsostatic presses are an essential tool in various industries, offering efficient and effective solutions for material processing. These presses utilize equal pressure in all directions to achieve uniform shaping and densification of materials.

Learn More

Comprehensive Overview of Cold Isostatic Pressing Services

1 year agoCold Isostatic Pressing (CIP) services play a crucial role in various industries, providing solutions for sterilization and compacting powders. These services offer a wide range of capabilities, ensuring the highest quality and efficiency.

Learn More

How FTIR Pellet Press Works in Sample Preparation for Spectroscopy Analysis

1 year agoFTIR (Fourier Transform Infrared) spectroscopy is a powerful analytical technique for identifying and characterizing chemical compounds based on their infrared absorption spectra.

Learn More

Understanding Cold Isostatic Pressing (CIP) and its Applications

1 year agoCold Isostatic Pressing (CIP) is a versatile manufacturing process that is widely used in various industries. It involves applying equal pressure from all directions to a material in order to achieve uniform compaction. This process is especially beneficial for materials with complex shapes or delicate structures. CIP is also known as isostatic compaction or hydrostatic pressing.

Learn More

WIP – Warm Isostatic Press Equipment: Design, Features, and Benefits

1 year agoKinTek specializes in designing and building Warm Isostatic Presses (WIP) for various applications. These systems can be either gas or liquid pressurized and are commonly used for plastics and laminated products. WIPs are custom-built to accommodate different pressure levels, ranging from low pressure to extreme pressures.

Learn More

How Isostatic Presses Help Eliminate Defects in Materials

2 years agoIsostatic pressing is a manufacturing process that is used to eliminate defects in materials.

Learn More

Comprehensive Guide to Isostatic Pressing: Types, Processes, and Features(3)

2 years agoIsostatic pressing is a versatile manufacturing process that is widely used in various industries. It involves subjecting a material to equal pressure from all directions to achieve uniform density and shape. Isostatic pressing offers numerous advantages, such as the ability to produce complex shapes, uniformity in material properties, and high precision.

Learn More