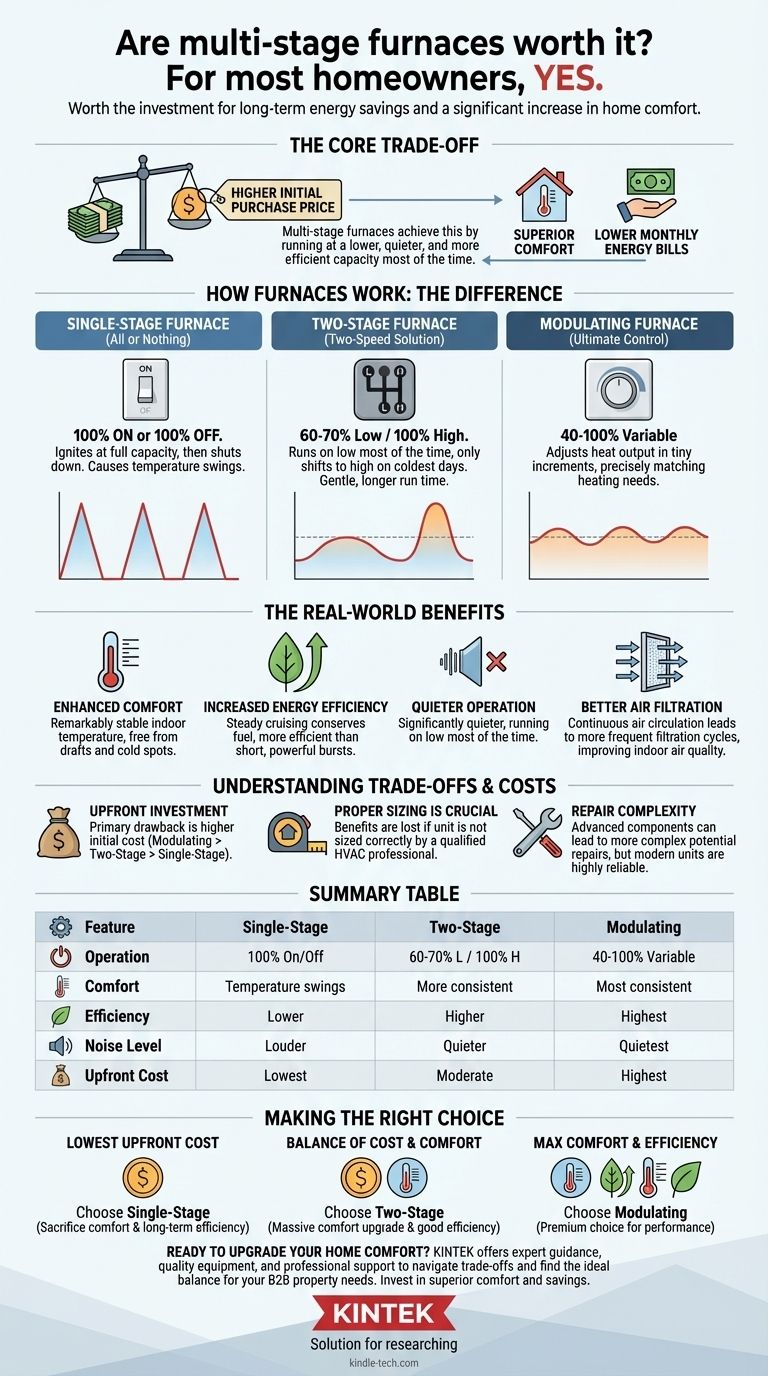

For most homeowners, yes. A multi-stage furnace is worth the investment if your priority is long-term energy savings and, more importantly, a significant increase in home comfort. While they have a higher upfront cost than basic single-stage models, they operate more efficiently and provide more consistent heat, which addresses the common issues of temperature swings and noisy operation.

The core decision is a trade-off: a higher initial purchase price for a furnace that delivers superior comfort and lower monthly energy bills. Multi-stage furnaces achieve this by running at a lower, quieter, and more efficient capacity most of the time, only using full power when absolutely necessary.

How Furnaces Actually Work: Single-Stage vs. Multi-Stage

To understand the value, you first need to understand the fundamental difference in how these systems operate. The "stages" refer to the levels of heat output the furnace can produce.

The "All or Nothing" Approach: Single-Stage Furnaces

A single-stage furnace operates like a simple light switch: it's either 100% on or 100% off.

It ignites at full capacity, runs until the thermostat's target temperature is met, and then shuts down completely. This on-and-off cycling is what causes noticeable temperature swings in your home.

The Two-Speed Solution: Two-Stage Furnaces

A two-stage furnace (a common type of multi-stage) operates more like a car's transmission. It has a low-speed setting and a high-speed setting.

It will typically start and run on its first stage, using around 60-70% of its total capacity. This gentle, longer run time is sufficient to heat your home on most mild to moderately cold days.

Only on the coldest days will it shift into the second stage (100% capacity) to meet the higher heating demand.

The Ultimate Control: Modulating Furnaces

A modulating furnace is the most advanced type of multi-stage system. Instead of just one or two settings, it operates like a dimmer switch, adjusting its heat output in tiny increments.

It can modulate its capacity anywhere from 40% to 100%, precisely matching the home's heating needs at any given moment. This provides the most consistent temperature and the highest level of energy efficiency.

The Real-World Benefits Beyond the Spec Sheet

The advantages of a multi-stage system go far beyond a simple number on an energy bill. They change the entire feel of your home's environment.

Enhanced Comfort and Consistent Temperatures

This is the most significant benefit. By running for longer periods at a lower output, multi-stage furnaces eliminate the peaks and valleys of a single-stage system.

The result is a remarkably stable indoor temperature, free from the drafts and cold spots that occur when a furnace is constantly cycling on and off.

Increased Energy Efficiency

Running a furnace at a lower capacity for a longer time is more energy-efficient than short, powerful bursts.

Think of it like city driving versus highway driving. The constant starting and stopping of a single-stage furnace wastes fuel, while the steady cruising of a multi-stage furnace conserves it.

Quieter Operation

The loud roar of a furnace kicking on is almost always from a single-stage unit firing up at 100% power and fan speed.

Because a multi-stage furnace spends most of its time on a low setting, its operation is significantly quieter, creating a more peaceful indoor environment.

Better Air Filtration

Since the furnace fan runs more consistently, it continuously circulates air through your home's filter. This leads to more frequent filtration cycles, which can help capture more dust, pollen, and other airborne particles, improving overall indoor air quality.

Understanding the Trade-offs and Costs

While the benefits are clear, a multi-stage furnace is not the automatic choice for everyone. You must consider the downsides to make an objective decision.

The Upfront Investment

The primary drawback is cost. A two-stage furnace will cost more than a comparable single-stage model, and a modulating furnace will cost more than a two-stage. This initial investment is the main factor to weigh against long-term savings and comfort.

The Importance of Proper Sizing

The benefits of a multi-stage system are completely lost if the unit is not sized correctly for your home by a qualified HVAC professional.

An oversized two-stage furnace will heat the house too quickly even on its low setting, causing it to cycle on and off just like a single-stage unit and negating all of its advantages.

Repair Complexity

With more advanced components like variable-speed motors and multi-stage gas valves, repairs can potentially be more complex and expensive than on a simpler single-stage furnace. However, modern units from reputable manufacturers are highly reliable.

Making the Right Choice for Your Home

Your decision should be based on your specific priorities for cost, comfort, and long-term performance.

- If your primary focus is the lowest possible upfront cost: A single-stage furnace is the most budget-friendly initial purchase, but you will sacrifice comfort and long-term efficiency.

- If your primary focus is a balance of cost and comfort: A two-stage furnace represents the sweet spot, offering a massive comfort upgrade and good efficiency for a moderate increase in price.

- If your primary focus is maximum comfort and long-term efficiency: A modulating furnace provides the most stable temperatures and lowest operating costs, making it the premium choice for those who prioritize performance.

Ultimately, choosing a furnace is an investment in your home's core comfort system, and understanding this trade-off empowers you to select the unit that best aligns with your budget and goals.

Summary Table:

| Feature | Single-Stage Furnace | Two-Stage Furnace | Modulating Furnace |

|---|---|---|---|

| Operation | 100% On or Off | 60-70% Low / 100% High | 40-100% Variable |

| Comfort | Temperature swings | More consistent | Most consistent |

| Efficiency | Lower | Higher | Highest |

| Noise Level | Louder | Quieter | Quietest |

| Upfront Cost | Lowest | Moderate | Highest |

Ready to Upgrade Your Home Comfort?

At KINTEK, we understand that choosing the right furnace is crucial for your home's efficiency and comfort. Whether you're a homeowner seeking consistent temperatures or a property manager aiming for long-term energy savings, our expertise in HVAC solutions ensures you get the perfect system tailored to your needs.

Why Choose KINTEK?

- Expert Guidance: We help you navigate the trade-offs between single-stage, two-stage, and modulating furnaces to find the ideal balance of cost and performance.

- Quality Equipment: From reliable two-stage models to advanced modulating systems, we provide durable, energy-efficient options that reduce monthly bills and enhance indoor air quality.

- Professional Support: Our team ensures proper sizing and installation to maximize your furnace's lifespan and efficiency.

Don't settle for uneven heating or high energy costs—contact KINTEK today for a personalized consultation and invest in a furnace that delivers superior comfort and savings for years to come!

Visual Guide

Related Products

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

- 1700℃ Laboratory Quartz Tube Furnace with Alumina Tube Tubular Furnace

- 1400℃ Laboratory Quartz Tube Furnace with Alumina Tube Tubular Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

People Also Ask

- Why does heating increase temperature? Understanding the Molecular Dance of Energy Transfer

- What is a multi-position furnace? The Ultimate Guide to Flexible HVAC Installation

- What are the four main types of sensors? A Guide to Power Source and Signal Type

- How are tube furnaces classified based on the orientation of the tube? Choose the Right Design for Your Process

- What is a muffle vs tube furnace? Choose the Right High-Temp Tool for Your Lab