Ultimately, there is no single temperature for annealing. The correct temperature is determined entirely by the specific material being treated and the desired outcome. For example, a low-hydrogen annealing process for steel may require a minimum of 200°C to allow hydrogen atoms to diffuse out, whereas a full anneal to soften the same steel would require much higher temperatures.

Annealing is not one process but a family of heat treatments. The target temperature is a carefully chosen variable, selected based on the material's unique properties—like its recrystallization point—and the specific goal, whether that's relieving stress, increasing softness, or refining the atomic structure.

The Purpose of Annealing: More Than Just Heating

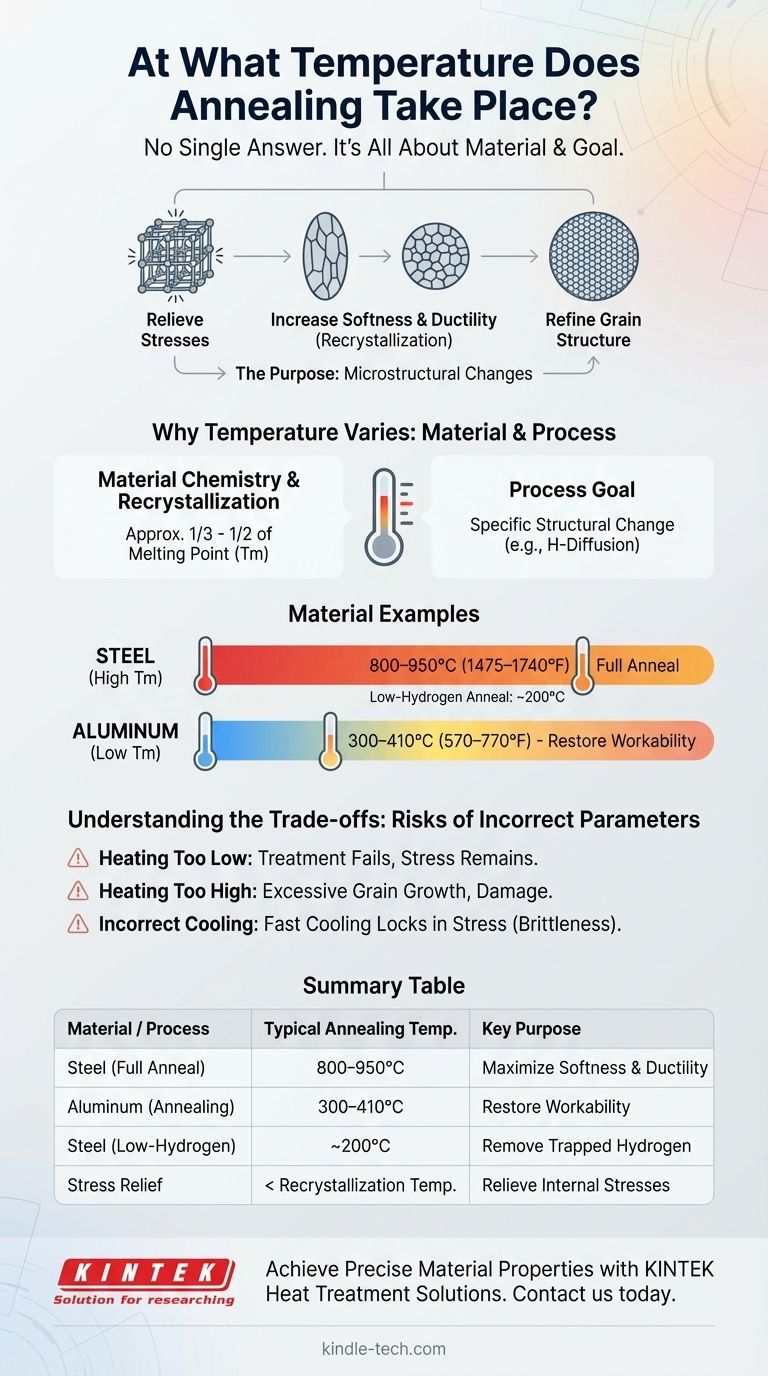

To understand why temperature varies, you must first understand what annealing accomplishes at a microscopic level. The goal is to induce specific changes in a material's crystal structure, or "microstructure."

Relieving Internal Stresses

Processes like bending, welding, or machining introduce stress into a material's atomic lattice. Heating the material gives the atoms enough energy to move slightly, allowing them to settle into more stable, lower-energy positions. This relieves the internal stress without changing the material's fundamental properties.

Increasing Softness and Ductility

When a metal is "cold worked" (shaped at room temperature), its crystal grains become distorted and elongated, making it harder and more brittle. Annealing heats the material above its recrystallization temperature, allowing new, strain-free grains to form. This process, called recrystallization, effectively resets the microstructure, restoring softness and ductility.

Refining Grain Structure

The size and uniformity of a material's crystal grains significantly impact its mechanical properties. By carefully controlling the annealing temperature and cooling rate, engineers can produce a fine, uniform grain structure that often provides an optimal balance of strength and toughness.

Why Temperature Varies: Material and Process

The required temperature is a direct function of the material's chemistry and the specific structural change you want to achieve.

The Role of Recrystallization Temperature

For most metals, the most important factor is the recrystallization temperature. This is the temperature at which new grains begin to form in a cold-worked material. A common rule of thumb is that this temperature is approximately one-third to one-half of the material's melting point (measured in an absolute scale like Kelvin).

Example: Steel vs. Aluminum

The difference is clear when comparing materials.

- Steel: As a high-melting-point alloy, steel requires high annealing temperatures. A "full anneal" typically occurs between 800–950°C (1475–1740°F).

- Aluminum: With a much lower melting point, aluminum can be annealed at significantly lower temperatures, generally between 300–410°C (570–770°F).

Process-Specific Temperatures

Sometimes, the goal isn't full recrystallization. The reference to low hydrogen annealing (or "hydrogen bake-out") is a perfect example. Here, the goal is simply to give trapped hydrogen atoms enough thermal energy to diffuse out of the steel, preventing hydrogen embrittlement. This requires a much lower temperature—around 200°C—than a full anneal because you are not trying to regrow the crystal grains.

Understanding the Trade-offs

Selecting the wrong temperature or process parameters can be worse than not annealing at all.

Heating Too Low

If the temperature does not reach the necessary threshold for the intended process (e.g., recrystallization), the treatment will fail. You will have expended energy and time with no benefit, and the material will remain stressed or brittle.

Heating Too High (Overshooting)

Exceeding the optimal annealing temperature can cause excessive grain growth. Large grains can decrease a material's strength and toughness. In extreme cases, overheating can lead to permanent damage or even begin to melt the material.

Incorrect Cooling Rate

Annealing is a two-part process: heating and cooling. The cooling rate is just as critical as the temperature. Cooling too quickly can lock in stress or create a hard, brittle structure (like martensite in steel), completely defeating the purpose of making the material softer. A proper anneal almost always involves very slow cooling.

Determining the Correct Annealing Temperature

To apply this correctly, you must first define your objective. Consult material-specific datasheets for precise temperature ranges.

- If your primary focus is stress relief after machining or welding: You can often use a lower-temperature process, known as sub-critical annealing, that doesn't fundamentally change the grain structure.

- If your primary focus is to maximize softness for forming: You must perform a full anneal by heating the material above its upper critical temperature and ensuring a very slow cooling rate.

- If your primary focus is removing trapped gases like hydrogen: A specific low-temperature bake-out, often between 200-300°C for steels, is sufficient and avoids altering the material's core strength.

Successful annealing depends on treating temperature not as a fixed number, but as a precise tool to achieve a specific microstructural goal.

Summary Table:

| Material / Process | Typical Annealing Temperature Range | Key Purpose |

|---|---|---|

| Steel (Full Anneal) | 800–950°C (1475–1740°F) | Maximize softness & ductility |

| Aluminum (Annealing) | 300–410°C (570–770°F) | Restore workability |

| Steel (Low-Hydrogen Anneal) | ~200°C (392°F) | Remove trapped hydrogen |

| Stress Relief (Sub-critical) | Below recrystallization temperature | Relieve internal stresses |

Achieve precise material properties with the right annealing equipment. The correct temperature is critical for success—whether you're working with steel, aluminum, or other metals. KINTEK specializes in lab furnaces and thermal processing equipment designed for accurate, repeatable heat treatment. Our solutions help you relieve stress, improve ductility, and refine grain structure with confidence. Contact us today to discuss your laboratory's annealing needs and discover how our expertise can enhance your results.

Get a Custom Quote for Your Lab

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

People Also Ask

- Can dissimilar metals be brazed or braze welded? A Guide to Strong, Reliable Joints

- What are vacuum furnaces used for? Unlock Ultimate Material Purity and Performance

- What is the difference between welding and vacuum brazing? Choose the Right Joining Method for Your Project

- What is a vacuum furnace used for? Unlock Purity in High-Temperature Processing

- What is brazing in heat treatment? Achieve Superior Joint Quality and Efficiency