Absolutely. Brazing is not only a viable method for joining dissimilar metals; it is one of the most effective and widely used techniques for this exact purpose. Unlike welding, which melts the base metals together, brazing uses a filler metal with a lower melting point to create a strong metallurgical bond, avoiding many of the complications that arise when trying to fuse two different materials.

While brazing is an ideal solution for joining dissimilar metals, success depends entirely on managing differences in thermal expansion and selecting the correct filler metal and heating process to ensure metallurgical compatibility.

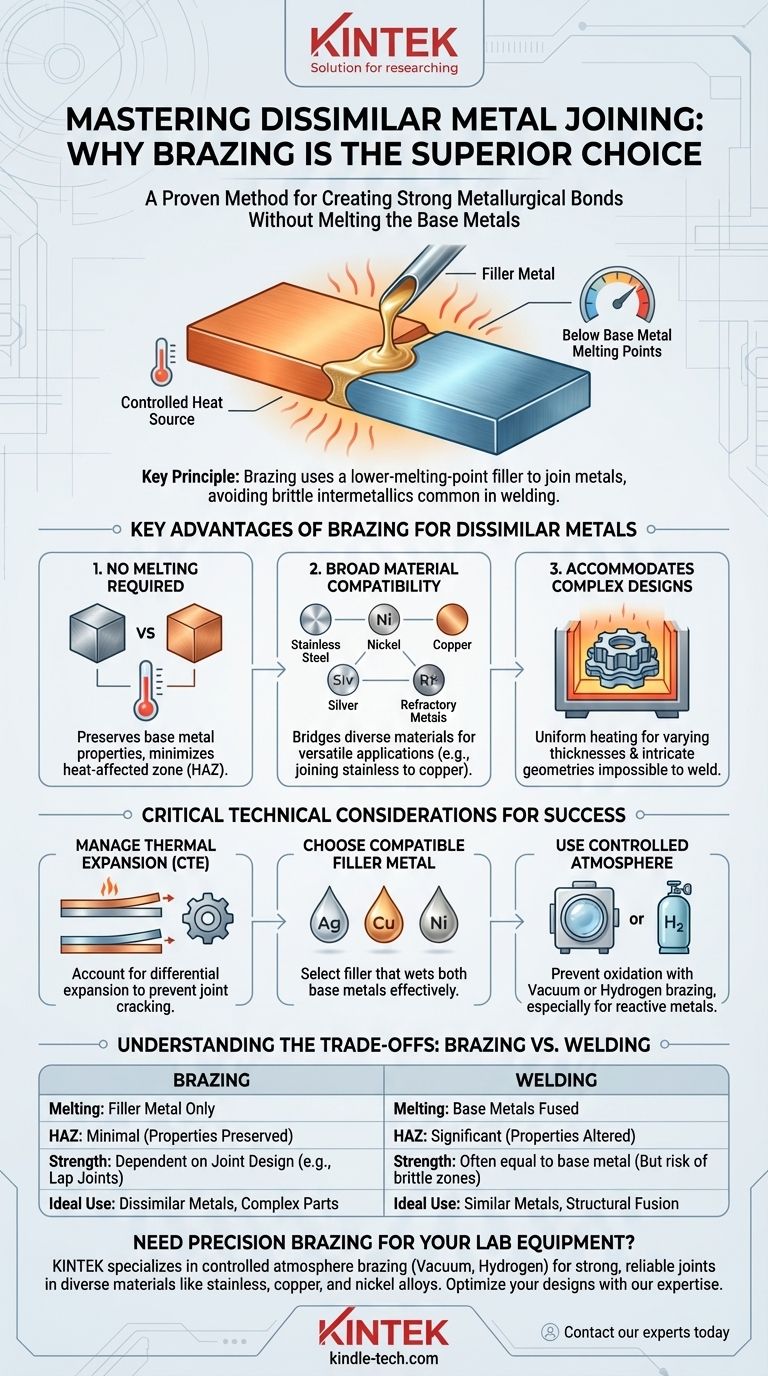

Why Brazing Excels at Joining Dissimilar Metals

The core advantage of brazing comes from its lower process temperature. This single factor makes it uniquely suited for creating strong bonds between metals that could not be easily welded together.

The Fundamental Principle: No Melting Required

Brazing works by heating two or more base metals to a temperature below their melting points. A filler metal is then introduced, which melts and is drawn into the joint by capillary action.

This process creates a strong, permanent bond without fusing the parent materials. This avoids the formation of brittle intermetallic compounds that often plague the welding of dissimilar metals.

Broad Material Compatibility

Brazing provides a bridge between a wide range of materials. It is commonly used to join various combinations of stainless steel, nickel, copper, and silver.

Specialized techniques like hydrogen brazing are used for materials like copper, silver, and nickel alloys, while vacuum brazing is necessary for joining reactive metals to high-performance refractory metals.

Accommodating Complex Designs

Processes like furnace brazing are exceptionally versatile. They can uniformly heat entire assemblies, making them ideal for joining parts with varying thicknesses or intricate, complex geometries that would be difficult or impossible to weld.

Key Technical Considerations

Successfully brazing dissimilar metals requires careful attention to a few critical factors. Overlooking these can lead to weak joints or component failure.

Managing Thermal Expansion

Different metals expand and contract at different rates when heated and cooled. This difference in the coefficient of thermal expansion (CTE) is the single most important challenge.

If not accounted for, this differential movement can create massive internal stress, causing the joint to crack during cooling or fail later in service. Proper joint design and controlled heating/cooling cycles are essential to manage this.

Choosing the Right Filler Metal

The braze filler metal must be metallurgically compatible with both base metals. It must be able to wet and bond to each surface effectively.

Common filler families include alloys based on silver, copper, nickel, and gold. The choice depends on the service temperature, strength requirements, and the specific base metals being joined.

Using a Controlled Atmosphere

Most high-integrity brazing is performed in a controlled atmosphere to prevent oxidation. Oxides on the surface of the metals will prevent the filler from wetting the joint and creating a bond.

Vacuum brazing is used for reactive metals (like titanium) and refractory metals, as it removes the oxygen that would cause contamination. Hydrogen brazing is another common method that creates a "reducing" atmosphere, which actively removes surface oxides from metals like copper and nickel.

Understanding the Trade-offs: Brazing vs. Welding

While brazing is often the superior choice for dissimilar metals, it's important to understand its relationship to welding.

Joint Strength and Design

A well-designed brazed joint can be as strong as, or even stronger than, the parent metals. However, the strength is concentrated in the thin layer of filler metal, requiring proper joint design (like lap joints) to maximize the bonding surface area.

The Heat-Affected Zone (HAZ)

Brazing's lower temperatures create a much smaller and less impactful heat-affected zone (HAZ) compared to welding. This means the properties of the base metals (like temper or hardness) are better preserved, which is a significant advantage.

When Welding Is an Alternative

Techniques like TIG and laser welding can also join dissimilar metals, but the process is generally more complex and carries a higher risk. Welding is often chosen when a direct fusion is necessary for the application, such as in the manufacturing of some sensor wires.

Making the Right Choice for Your Application

Selecting the right process hinges on your materials and your final goal.

- If your primary focus is preserving the base metals' properties: Brazing is superior due to its lower process temperatures and minimal heat-affected zone.

- If you are joining reactive or high-temperature refractory metals: A controlled atmosphere process like vacuum brazing is non-negotiable to prevent oxidation and ensure a sound bond.

- If your materials have very different expansion rates: Your design must prioritize proper joint clearance and a controlled heating/cooling cycle to prevent stress-induced failure.

By carefully considering these principles, you can confidently use brazing to create reliable, high-strength joints between a vast range of dissimilar materials.

Summary Table:

| Key Factor | Importance for Dissimilar Metal Brazing |

|---|---|

| Thermal Expansion (CTE) | Critical to manage; differential expansion can cause joint stress and cracking if not controlled. |

| Filler Metal Selection | Must be metallurgically compatible with both base metals (e.g., silver, copper, or nickel alloys). |

| Atmosphere Control | Prevents oxidation; vacuum or hydrogen brazing is essential for reactive or high-performance metals. |

| Joint Design | Lap joints maximize bonding area; proper clearance ensures capillary action and strength. |

Need to join dissimilar metals for your laboratory equipment? KINTEK specializes in precision brazing solutions for lab equipment and consumables, ensuring strong, reliable bonds between materials like stainless steel, copper, and nickel alloys. Our expertise in controlled atmosphere brazing (including vacuum and hydrogen processes) guarantees oxidation-free joints with minimal heat impact. Let us help you optimize your component designs for durability and performance. Contact our experts today to discuss your project requirements!

Visual Guide

Related Products

- Ultra-High Temperature Graphite Vacuum Graphitization Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Graphite Vacuum Furnace IGBT Experimental Graphitization Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the conductivity of graphite? Understanding Its High Electrical & Thermal Properties

- Why does graphite not melt? Unlocking the Secrets of Its Extreme Heat Resistance

- At what temperature does graphite melt? Understanding Its Extreme Phase Change

- Why is graphite so hard to melt? The Secret Lies in Its Atomic Structure

- What are the mechanical properties of graphite? Harnessing Rigidity and Managing Brittleness