Yes, diamonds can be made artificially, and they are chemically and physically identical to those mined from the Earth. These are not imitations like cubic zirconia; they are true diamonds, created by replicating the extreme conditions of their natural formation within a controlled laboratory environment.

The core takeaway is that humanity has successfully reverse-engineered one of nature's most extreme geological processes. Lab-grown diamonds are not fakes; they are the result of technology creating the specific high-pressure, high-temperature conditions required for carbon to crystallize into diamond.

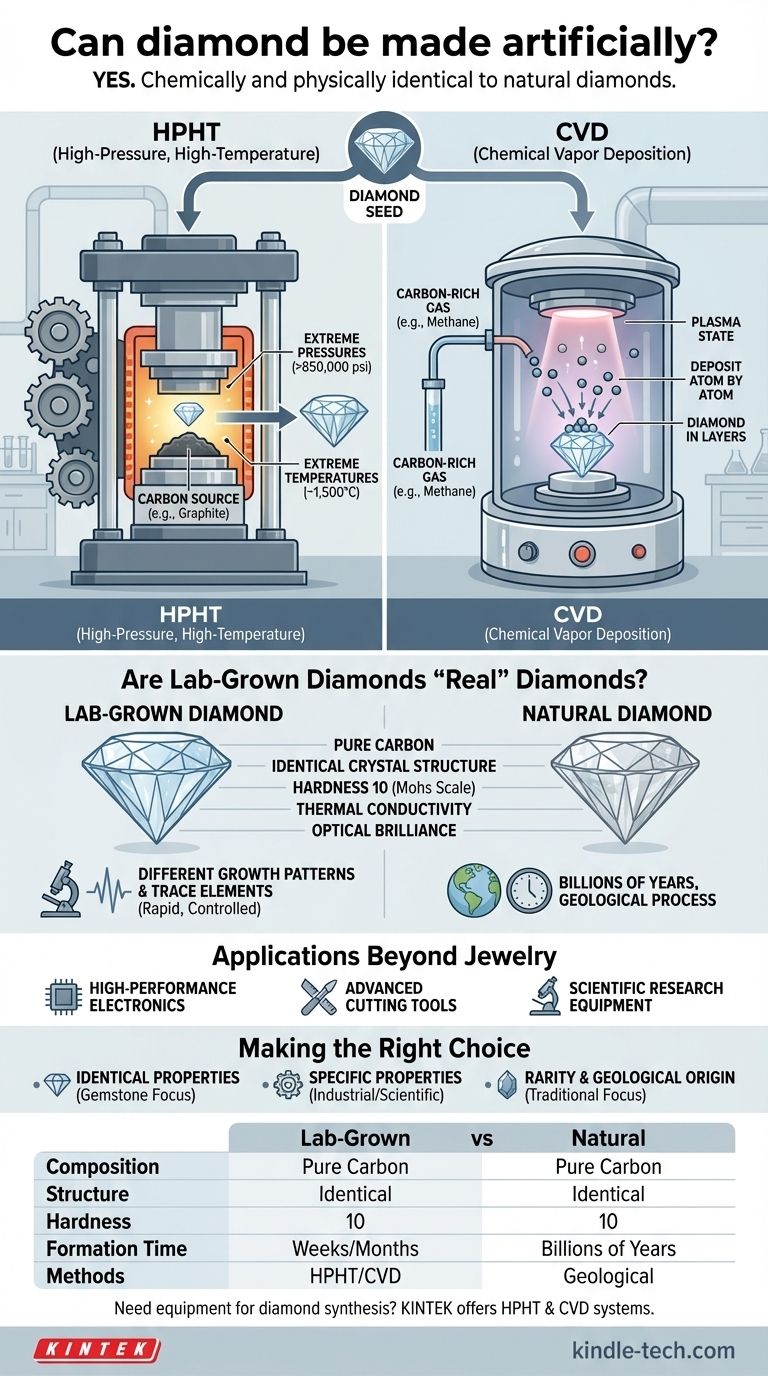

The Two Primary Methods of Diamond Synthesis

To create a diamond, you need to force carbon atoms into a highly stable, rigid crystal lattice. Scientists have developed two primary methods to accomplish this, both of which begin with a tiny diamond "seed."

High-Pressure, High-Temperature (HPHT)

The HPHT method directly mimics the natural process that occurs deep within the Earth's mantle.

A small diamond seed is placed in a chamber with a source of pure carbon, like graphite. The chamber is then subjected to immense pressures (over 850,000 psi) and extreme temperatures (around 1,500°C), causing the carbon source to crystallize onto the seed.

Chemical Vapor Deposition (CVD)

The CVD method builds a diamond atom by atom, more like growing a crystal than forging one.

A diamond seed is placed inside a sealed vacuum chamber filled with a carbon-rich gas, such as methane. This gas is heated to a plasma state, causing carbon atoms to separate and rain down, depositing onto the seed and growing the diamond in layers.

As noted in technical literature, there are several advanced variations of this method, including hot filament CVD and Microwave Plasma CVD (MPCVD), each offering fine-tuned control over the growth process.

Are Lab-Grown Diamonds "Real" Diamonds?

This is the most common point of confusion. From a scientific standpoint, the answer is an unequivocal yes.

Identical Chemical and Physical Properties

A lab-grown diamond has the same chemical composition (pure carbon) and crystal structure as a natural diamond. This means it possesses the same hardness, thermal conductivity, and optical brilliance.

Distinguishing Between Natural and Synthetic

While they are visually identical to the naked eye, gemologists can differentiate them using specialized equipment.

Natural diamonds often contain minute amounts of nitrogen and have specific growth patterns formed over billions of years. Lab-grown diamonds have different, more uniform growth patterns and trace elements that reflect their rapid, controlled creation.

Understanding the Trade-offs and Quality

Creating a perfect diamond, even in a lab, is exceptionally difficult. The process requires a level of control that pushes the boundaries of material science.

Controlled Environment vs. Natural Chaos

A laboratory offers a highly controlled environment, which allows for the creation of diamonds with specific properties for industrial or technological use.

However, just as with natural diamonds, inclusions and imperfections can still occur. The reference that the quality of each diamond varies is a critical point; not all synthetic diamonds are flawless.

Applications Beyond Jewelry

The ability to control the creation process has unlocked new applications. By introducing specific elements during growth, diamonds can be engineered for use in high-performance electronics, advanced cutting tools, and scientific research equipment.

Making the Right Choice for Your Goal

Whether a lab-grown diamond is the "right" choice depends entirely on its intended purpose and your priorities.

- If your primary focus is a gemstone with identical properties to a mined diamond: A lab-grown diamond is a chemically and visually indistinguishable option that often presents a different value proposition.

- If your primary focus is industrial or scientific application: The choice between CVD and HPHT will be determined by the specific properties required for the tool or electronic component.

- If your primary focus is the rarity and geological origin of a gemstone: A natural diamond, with its billion-year history and unique journey to the Earth's surface, remains the traditional choice.

Ultimately, the creation of synthetic diamonds represents a remarkable achievement in materials science, giving us direct access to one of nature's most extraordinary materials.

Summary Table:

| Aspect | Lab-Grown Diamond | Natural Diamond |

|---|---|---|

| Composition | Pure Carbon | Pure Carbon |

| Crystal Structure | Identical | Identical |

| Hardness | 10 on Mohs Scale | 10 on Mohs Scale |

| Formation Time | Weeks to Months | Billions of Years |

| Primary Methods | HPHT, CVD | Geological Process |

Need a reliable source for lab equipment to support diamond synthesis or material research? KINTEK specializes in providing high-quality lab equipment and consumables for advanced material science applications, including CVD and HPHT systems. Our expertise ensures you get the precise tools needed for controlled, efficient diamond growth. Contact our experts today to discuss how we can support your laboratory's specific needs!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- CVD Diamond Domes for Industrial and Scientific Applications

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- What is the use of KBr? Master Sample Prep for Accurate IR Spectroscopy

- Why are KBr pellets used in FTIR? Achieve Clear, Accurate Solid Sample Analysis

- What is the pressed powder pellet method? A Guide to Accurate FTIR Sample Preparation

- How does a laboratory hydraulic press improve XRF accuracy for catalyst samples? Enhance Precision & Signal Stability

- What is the pellet technique in IR? Master Solid Sample Preparation for Clear Spectroscopy