Contrary to what intuition might suggest, heat can absolutely travel through a vacuum. While the modes of heat transfer we experience most often—conduction and convection—require a medium, the third mode, thermal radiation, does not. This is because radiation transmits energy in the form of electromagnetic waves, which can propagate through the emptiness of space, just as sunlight travels from the Sun to the Earth.

The core principle is this: the absence of matter in a vacuum stops heat transfer by conduction and convection, but it presents no barrier to thermal radiation. Understanding this distinction is fundamental to engineering everything from a simple thermos to a deep-space satellite.

The Three Channels of Heat Transfer

To understand why a vacuum is unique, we must first distinguish between the three ways heat moves from one place to another. Most scenarios on Earth involve a combination of all three.

Conduction: The Particle-to-Particle Chain

Conduction is heat transfer through direct contact. Think of a metal spoon left in a hot cup of coffee; the handle gets warm because the heat energy is passed directly from one vibrating molecule to the next.

This process requires a medium. With no particles to vibrate and collide, conduction is impossible in a perfect vacuum.

Convection: The Moving Fluid

Convection is heat transfer through the bulk movement of fluids (liquids or gases). When you boil water, the water at the bottom heats up, becomes less dense, and rises, while cooler, denser water sinks to take its place, creating a current.

This process also requires a medium to create currents. Convection cannot occur in a vacuum.

Radiation: The Unseen Wave

Radiation is the transfer of heat via electromagnetic waves, primarily in the infrared spectrum. Every object with a temperature above absolute zero (-273.15°C) emits thermal radiation. Unlike conduction and convection, this energy needs no medium to travel.

This is the sole method of heat transfer in a vacuum. The Sun warming the Earth across 93 million miles of empty space is the ultimate example.

Understanding the Trade-offs and Applications

The unique properties of a vacuum create both powerful engineering opportunities and significant challenges. It is a perfect insulator against two forms of heat transfer, but it's completely transparent to the third.

The Power of Isolation

The most common application of a vacuum's properties is in insulation. A thermos, or Dewar flask, uses a vacuum sealed between two walls of glass or steel.

This vacuum effectively stops heat transfer by conduction and convection, keeping hot liquids hot and cold liquids cold for extended periods. The only remaining path for heat transfer is radiation, which is minimized by coating the walls with a reflective layer (like silver).

The Challenge of Cooling in Space

For spacecraft and satellites, getting rid of excess heat is a critical problem. Since space is a vacuum, they cannot use conduction or convection to shed the heat generated by electronics and solar exposure.

The only option is radiation. This is why spacecraft have large panels called radiators. These are designed to have a large surface area to radiate heat energy away into deep space as efficiently as possible.

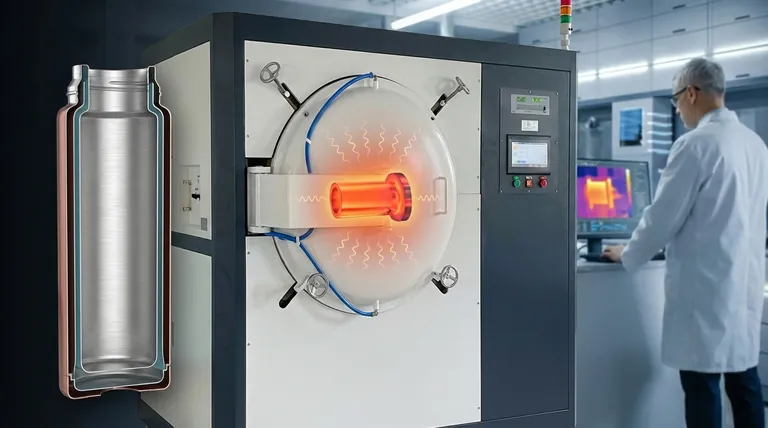

Precision Heating in a Vacuum Furnace

In manufacturing and materials science, heating a material in a vacuum is a powerful technique. By removing air, you eliminate unwanted chemical reactions like oxidation.

This allows for pure heating via radiation, ensuring the material's surface integrity is maintained. This process is used for heat-treating high-strength alloys, brazing complex components, and degassing metals to remove impurities.

Making the Right Choice for Your Goal

Understanding how heat behaves in a vacuum allows you to leverage its properties to solve specific engineering problems.

- If your primary focus is insulation: A vacuum is the most effective barrier to conduction and convection, making it the superior choice for high-performance thermal isolation.

- If your primary focus is heating in a pure environment: A vacuum allows for precise, non-contaminating heat transfer via radiation, protecting the workpiece from unwanted surface reactions.

- If your primary focus is cooling an object in a vacuum: Your only option is to maximize heat dissipation through radiation by engineering large, emissive surface areas.

Mastering this fundamental principle of physics is key to solving thermal management challenges across countless disciplines.

Summary Table:

| Heat Transfer Method | Medium Required? | Works in Vacuum? |

|---|---|---|

| Conduction | Yes | No |

| Convection | Yes | No |

| Radiation | No | Yes |

Need precise thermal management solutions for your lab? KINTEK specializes in lab equipment and consumables, including vacuum furnaces for contamination-free heating and custom thermal systems. Let our experts help you solve your unique thermal challenges—contact us today to discuss your application!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

People Also Ask

- What are the advantages of vacuum hardening? Achieve Superior Precision and Cleanliness for Critical Components

- What are the advantages of a vacuum furnace? Achieve Superior Purity and Control in Heat Treatment

- What are vacuum furnace parts? A Guide to the Core Systems for Precision Heat Treatment

- Where are vacuum furnaces used? Essential for High-Purity Heat Treatment in Critical Industries

- What is vacuum heat treatment process? Achieve Superior Control, Cleanliness, and Quality