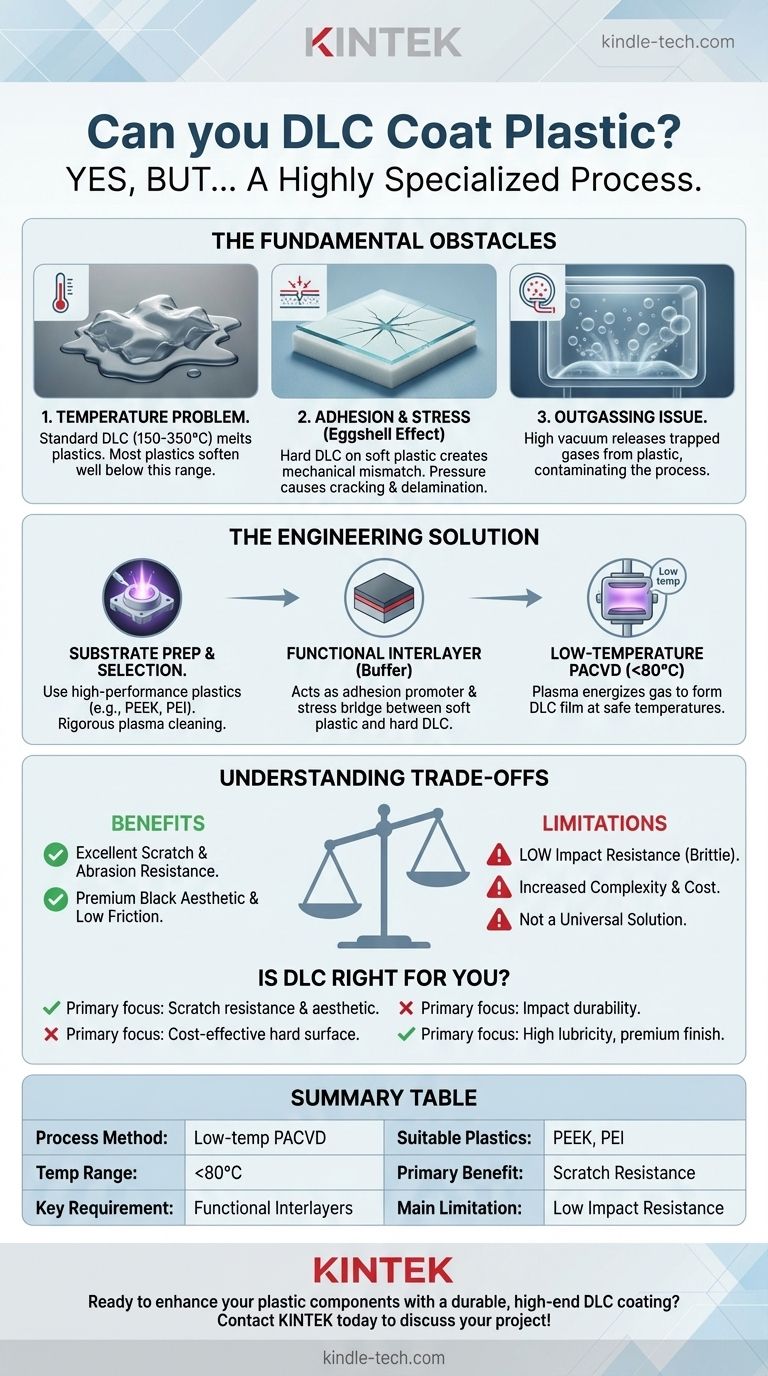

In short, yes, you can apply a Diamond-Like Carbon (DLC) coating to plastic, but it is a highly specialized process. Standard DLC application methods involve high temperatures that would melt or severely damage most polymer substrates. Therefore, success hinges entirely on using advanced, low-temperature deposition techniques and often requires specific intermediate layers to ensure the coating adheres properly.

Applying an extremely hard, rigid coating like DLC to a soft, flexible material like plastic presents a fundamental engineering challenge. The solution lies not in standard procedures, but in sophisticated, low-temperature processes designed specifically to bridge the vast differences between these two material classes.

The Fundamental Challenge: A Mismatch of Materials

Applying DLC to metal is a well-understood and routine process. Applying it to plastic introduces three significant obstacles that must be overcome with specialized engineering.

The Temperature Problem

Standard DLC deposition, whether through Physical Vapor Deposition (PVD) or Plasma-Assisted Chemical Vapor Deposition (PACVD), often operates at temperatures between 150°C and 350°C (300°F to 660°F).

Most common plastics, such as Acrylonitrile Butadiene Styrene (ABS) or Polycarbonate (PC), have a glass transition temperature (the point where they begin to soften) well below this range. Exposing them to these temperatures causes them to deform, warp, or even melt.

The Adhesion and Stress Problem

DLC coatings are exceptionally hard and rigid, while plastic substrates are soft and flexible. This creates a severe mechanical mismatch.

Imagine placing a thin sheet of glass on a foam pad. The glass is hard, but any pressure will cause the foam to deform, immediately cracking the glass. The same "eggshell effect" occurs with DLC on plastic. Furthermore, the two materials expand and contract with temperature changes at very different rates, creating immense internal stress that can cause the coating to delaminate or flake off.

The Outgassing Issue

The DLC deposition process occurs in a high-vacuum chamber. When plastics are placed in a vacuum, they tend to release trapped gases and moisture from within the material—a phenomenon known as outgassing.

This outgassing contaminates the vacuum environment, interfering with the coating process and leading to poor film quality and extremely weak adhesion.

How DLC on Plastic is Achieved

Engineers solve the mismatch between DLC and plastic by carefully controlling the process and strategically adding intermediate layers. This is not a simple one-step application but a multi-stage technical solution.

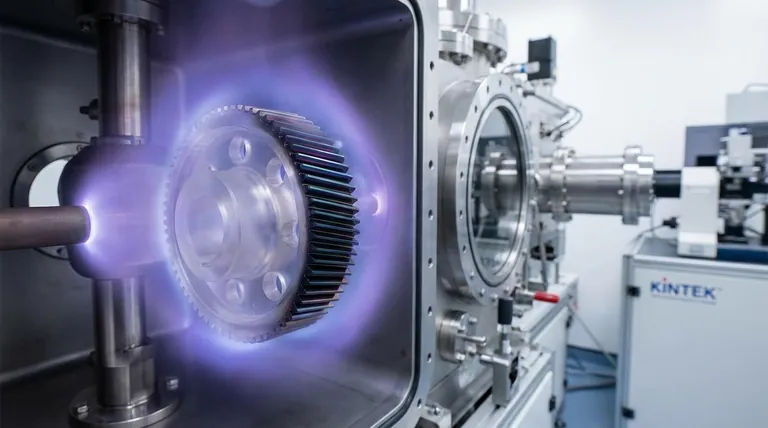

Low-Temperature PACVD

The primary enabler for coating plastics is low-temperature PACVD. In this process, a precursor gas (like a hydrocarbon) is energized by a plasma field.

The plasma provides the energy needed for the chemical reactions to form the DLC film on the substrate's surface. Because the energy comes from the plasma rather than high heat, the overall process temperature can be kept below 80°C (175°F), which is safe for many plastics.

The Critical Role of Interlayers

A direct DLC-on-plastic bond is often too weak and stressed to be reliable. To solve this, a functional interlayer (or "buffer layer") is deposited onto the plastic first.

This layer serves two purposes: it acts as a strong adhesion promoter for the subsequent DLC film, and its properties are designed to be a bridge between the soft plastic and the hard carbon. It is more flexible than DLC but more rigid than plastic, helping to manage stress from thermal expansion and mechanical flexing.

Substrate Selection and Preparation

Not all plastics are suitable for DLC coating. The best candidates are typically high-performance engineering plastics like PEEK or PEI (Ultem), which have higher thermal stability and lower outgassing rates.

Before coating, the plastic part must undergo rigorous pre-treatment, often involving a plasma cleaning step inside the vacuum chamber. This removes surface contaminants and activates the polymer surface, creating better chemical bonding sites for the interlayer.

Understanding the Trade-offs

While technically possible, applying DLC to plastic involves compromises that are critical to understand.

Performance is Substrate-Dependent

A DLC coating on plastic will not be as durable as DLC on steel. Its primary benefit is providing excellent scratch and abrasion resistance for the surface.

However, it offers very little impact resistance. A sharp blow will dent the soft plastic underneath, causing the rigid DLC layer to crack and fail. The performance of the final product is limited by the mechanical properties of the underlying plastic.

Increased Complexity and Cost

The specialized equipment, multi-step processes (interlayers, low-temp deposition), and expert knowledge required make coating plastic with DLC significantly more complex and expensive than standard metal coating.

This is not a commodity service. It is a high-end solution for applications where the performance benefits justify the substantial increase in cost.

Not a Universal Solution

The process is only viable for specific types of plastics and part geometries. Components with very deep or complex features can be difficult to coat evenly. Success is highly dependent on the specific polymer, the part's design, and the capabilities of the coating provider.

Is DLC the Right Choice for Your Plastic Part?

To determine if this advanced process is right for you, consider your primary goal.

- If your primary focus is premier scratch and abrasion resistance: DLC is one of the best solutions available, provided your plastic substrate is compatible and the high cost aligns with your product's value.

- If your primary focus is impact durability: DLC is a poor choice. The coating is brittle and will fail when the soft underlying plastic deforms from an impact.

- If your primary focus is a cost-effective hard surface: You should first explore simpler alternatives like specialized UV-cured hard lacquers or other polymer-based coatings that offer good scratch resistance at a fraction of the cost.

- If your primary focus is a premium black aesthetic with high lubricity: DLC excels at providing a smooth, low-friction, high-end finish, but be sure the mechanical trade-offs meet your product's real-world demands.

Ultimately, successfully coating plastic with DLC is an advanced engineering decision that requires a careful balance of material science, process capability, and application-specific requirements.

Summary Table:

| Key Consideration | Details |

|---|---|

| Process Method | Low-temperature Plasma-Assisted Chemical Vapor Deposition (PACVD) |

| Temperature Range | Below 80°C (175°F) to prevent plastic deformation |

| Key Requirement | Use of functional interlayers for adhesion and stress management |

| Suitable Plastics | High-performance engineering plastics like PEEK or PEI (Ultem) |

| Primary Benefit | Excellent scratch and abrasion resistance with a premium black finish |

| Main Limitation | Low impact resistance; performance is limited by the plastic substrate |

Ready to enhance your plastic components with a durable, high-end DLC coating?

At KINTEK, we specialize in advanced lab equipment and consumables, including specialized coating solutions for laboratory and industrial applications. Our expertise in low-temperature deposition techniques ensures that your plastic parts receive a superior DLC coating that provides exceptional scratch resistance and a premium aesthetic.

Whether you're working with high-performance polymers or need a coating that bridges the gap between flexibility and hardness, KINTEK has the technology and knowledge to meet your specific needs.

Contact us today to discuss your project and discover how our DLC coating services can add value to your products!

Visual Guide

Related Products

- Custom CVD Diamond Coating for Lab Applications

- CVD Diamond Cutting Tool Blanks for Precision Machining

- CVD Diamond Optical Windows for Lab Applications

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

People Also Ask

- What are the main machine parameters that you can use to optimize a PECVD process? Master Gas, Plasma, Pressure & Temperature

- What are the advantageous properties of thin films deposited by PECVD? Enhance Your Device Reliability

- What are the technical advantages of PECVD vs. CVD for CF2 films? Master Precision Nano-Engineering

- What is the difference between CVD and PECVD? Choose the Right Thin-Film Deposition Method

- How are film properties controlled using ICPCVD? Master Precise Atomic Bonding & High-Density Plasma Deposition

- Why can plasma-enhanced cvd PECVD operate at relatively lower temperature as compared to lpcvd? Unlock Low-Temp Thin Film Deposition

- What is the difference between plasma CVD and thermal CVD? Choose the Right Method for Your Substrate

- What are the uses of PECVD? A Guide to Low-Temperature Thin-Film Deposition