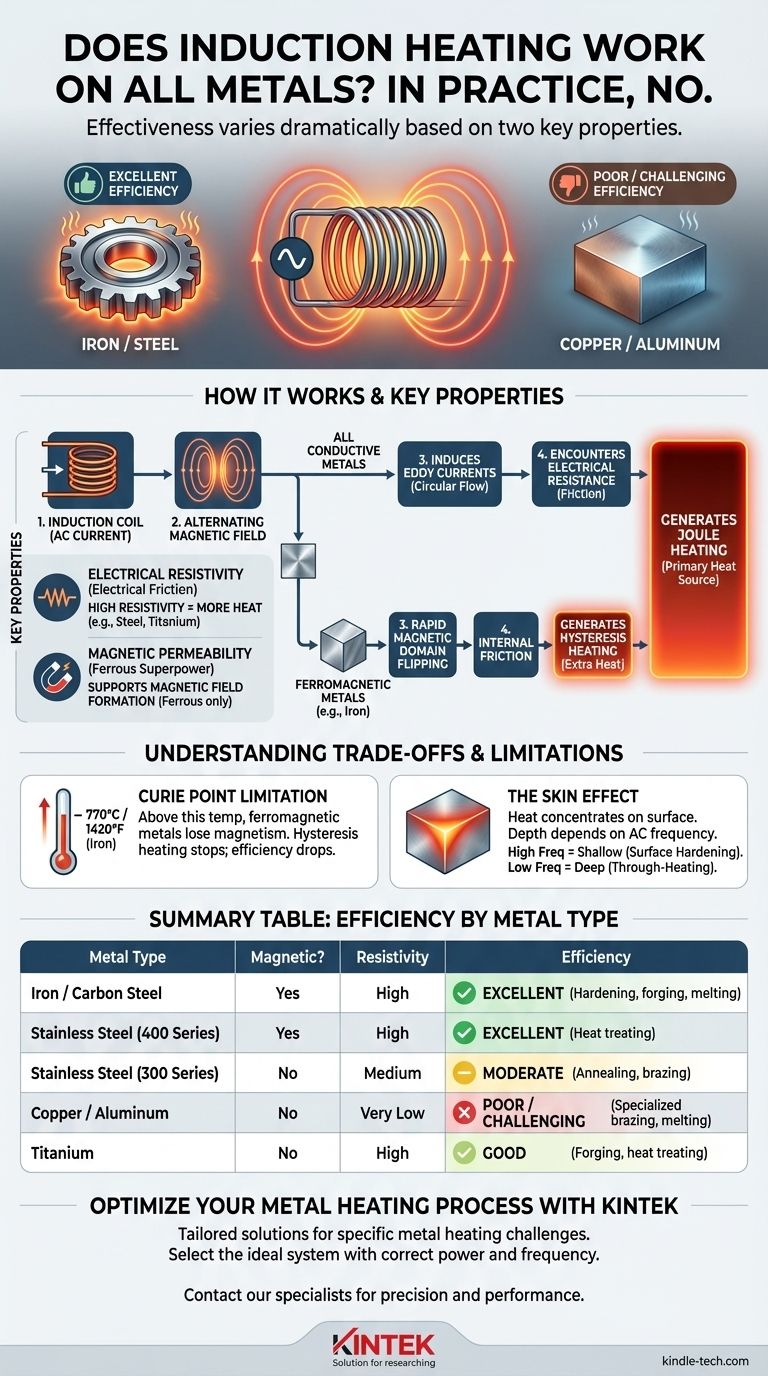

In practice, no. While induction heating works on nearly all electrically conductive metals, its effectiveness varies dramatically based on the material's specific properties. The process is highly efficient for metals like iron and steel but can be very inefficient for others like copper or aluminum, often requiring specialized equipment to achieve the desired results.

The success of induction heating hinges on two key material properties: electrical resistivity and magnetic permeability. Metals with high resistivity and high permeability heat exceptionally well, while those with low values are challenging to heat directly.

How Induction Heating Fundamentally Works

To understand why some metals heat better than others, you must first understand the core mechanism. The process is not about applying external heat; it's about causing the metal to heat itself from within.

The Role of an Alternating Magnetic Field

The process begins with an induction coil, typically made of copper tubing. A high-frequency alternating current (AC) is passed through this coil.

This AC current generates a powerful, rapidly changing magnetic field in the space within and around the coil.

Generating "Eddy Currents" in the Metal

When you place a conductive metal part into this magnetic field, the field induces circular electrical currents within the metal itself. These are known as eddy currents.

The Power of Resistance (Joule Heating)

These eddy currents are not flowing freely. They encounter the metal's own internal electrical resistance. As the currents push against this resistance, they generate intense, localized heat.

This phenomenon, known as Joule heating, is the primary way that all conductive metals are heated via induction.

The Two Properties That Determine Heating Efficiency

The differences in how metals respond to induction come down to two fundamental characteristics. A metal that is "good" for induction heating excels in one or both of these areas.

1. Electrical Resistivity

Resistivity is a measure of how strongly a material opposes the flow of electric current. Think of it as electrical friction.

A material with high resistivity will generate more heat from the same amount of eddy current. This is why steel and titanium, which have relatively high resistivity, heat very efficiently.

Conversely, copper and aluminum have very low resistivity. They are excellent conductors, meaning the eddy currents flow with little opposition, and therefore generate much less heat.

2. Magnetic Permeability (The Ferrous Metal Superpower)

For ferromagnetic metals like iron and carbon steel, a second, powerful heating effect occurs: hysteresis heating.

Magnetic permeability is the ability of a material to support the formation of a magnetic field. In ferromagnetic materials, the rapidly changing magnetic field from the coil causes the material's internal magnetic domains to flip back and forth millions of times per second.

This rapid flipping creates immense internal friction, which generates a significant amount of extra heat in addition to the Joule heating from eddy currents. This makes ferromagnetic metals exceptionally easy to heat with induction.

Understanding the Trade-offs and Limitations

While powerful, induction heating is governed by physical laws that create important practical limitations.

The Curie Point Limitation

The powerful hysteresis effect only works on ferromagnetic metals below a specific temperature known as the Curie point (around 770°C / 1420°F for iron).

Above this temperature, the metal loses its magnetic properties. The hysteresis heating effect stops completely, and heating efficiency drops significantly, relying solely on the less-effective Joule heating.

The "Skin Effect"

Induction heating does not heat the entire volume of a part uniformly at once. The eddy currents—and therefore the heat—are most concentrated on the surface of the material. This is called the skin effect.

The depth of this heated "skin" is determined by the frequency of the AC current. Higher frequencies produce very shallow heating, ideal for surface hardening. Lower frequencies penetrate deeper, which is necessary for through-heating or melting large parts.

Why Copper and Aluminum Are So Challenging

These metals combine two difficult properties: very low resistivity and non-magnetic nature (no hysteresis effect). They require significantly more power and often higher frequencies to induce strong enough eddy currents to generate useful heat.

Making the Right Choice for Your Application

Your choice of material and equipment settings must be aligned with your specific goal.

- If your primary focus is rapid, efficient heating: Use ferromagnetic materials like carbon steel, cast iron, or nickel.

- If you must heat non-magnetic metals like aluminum or copper: Plan for a system with higher power and a frequency optimized for the material and part size.

- If you need precise surface hardening: Use a very high frequency to concentrate the heat only on the outer skin of a ferrous part.

- If your goal is to melt a large billet: Use a lower frequency to ensure the magnetic field and heat can penetrate deep into the material's core.

Understanding these core principles moves you from simply using a tool to strategically controlling a powerful physical process.

Summary Table:

| Metal Type | Magnetic? | Resistivity | Induction Heating Efficiency | Common Applications |

|---|---|---|---|---|

| Iron / Carbon Steel | Yes (Ferromagnetic) | High | Excellent | Hardening, forging, melting |

| Stainless Steel (400 Series) | Yes (Ferromagnetic) | High | Excellent | Heat treating |

| Stainless Steel (300 Series) | No (Non-Magnetic) | Medium | Moderate | Annealing, brazing |

| Copper / Aluminum | No (Non-Magnetic) | Very Low | Poor / Challenging | Specialized brazing, melting (requires high power) |

| Titanium | No (Non-Magnetic) | High | Good | Forging, heat treating |

Optimize Your Metal Heating Process with KINTEK

Understanding the nuances of induction heating is key to maximizing efficiency and achieving perfect results in your lab or production line. Whether you're working with carbon steel, challenging non-ferrous metals like aluminum, or need precise surface hardening, the right equipment makes all the difference.

KINTEK specializes in advanced lab equipment and consumables, providing tailored solutions for your specific metal heating challenges. Our experts can help you select the ideal induction heating system with the correct power and frequency settings for your material and application.

Let us help you enhance your process. Contact our specialists today for a consultation and discover the KINTEK difference in precision and performance.

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Engineering Advanced Fine Ceramics Aluminum Oxide Al2O3 Heat Sink for Insulation

- Anti-Cracking Press Mold for Lab Use

- Benchtop Laboratory Freeze Dryer for Lab Use

People Also Ask

- What is the principle behind induction furnaces? Unlock Fast, Clean, and Efficient Metal Heating

- Does induction heating work on non metals? The Critical Role of Electrical Conductivity

- What is the melting loss of an induction furnace? Optimize Your Metal Yield and Energy Efficiency

- Does induction heating only work on metals? Unlocking the Science for Non-Metals

- What is the primary function of a vacuum arc melting furnace in RHEA preparation? Achieving Extreme Thermal Fusion

- Why high frequency is used in induction furnace? For Precise, Rapid, and Efficient Metal Melting

- Why is high-purity argon gas essential as a shielding gas during the arc melting of Ti-6Al-4V alloy?

- How does a vacuum resistance melting furnace prevent magnesium oxidation? Protect AM60 Alloy Purity