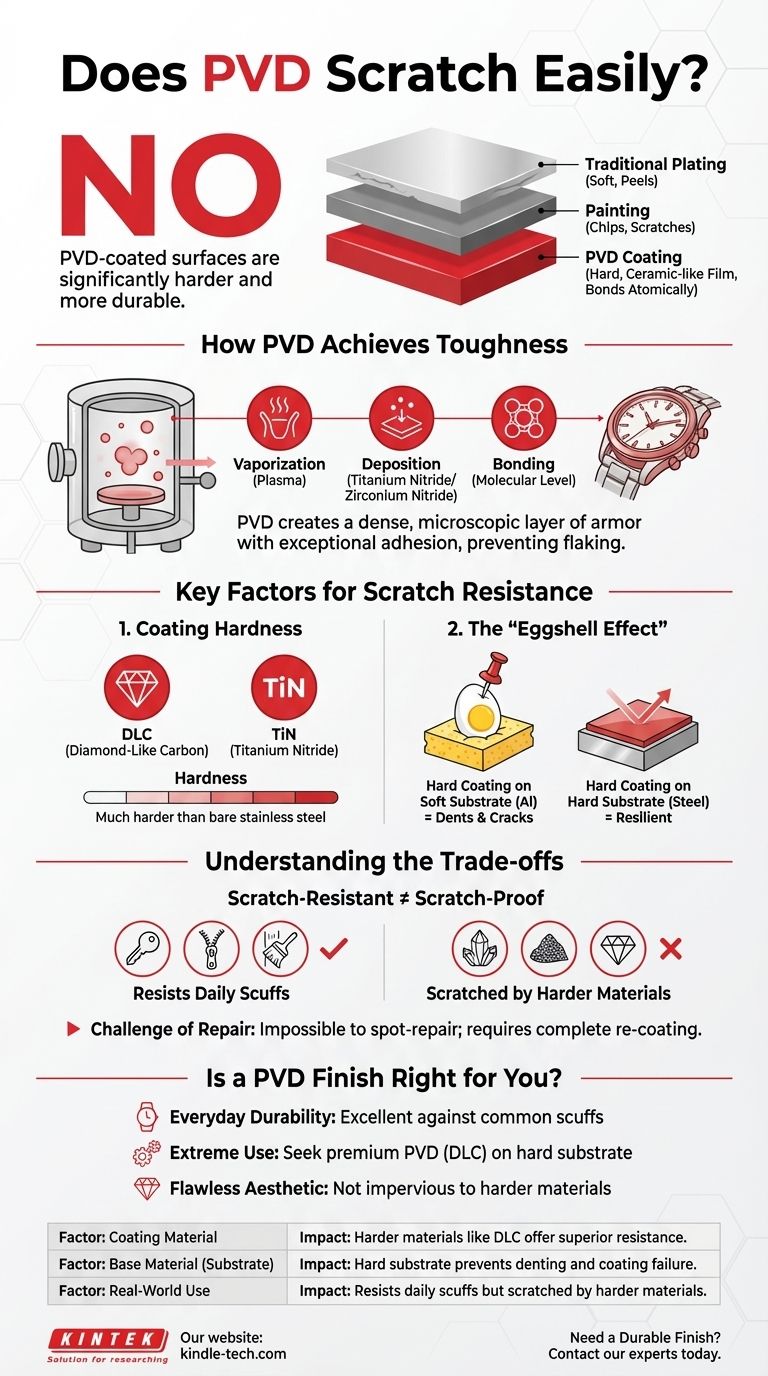

On the contrary, PVD-coated surfaces do not scratch easily. Physical Vapor Deposition (PVD) is a modern coating process that creates a finish that is significantly harder and more durable than traditional methods like electroplating or painting. The process bonds a thin film of a hard, ceramic-like material to a base metal at a molecular level, resulting in exceptional resistance to daily wear, scuffs, and corrosion.

The core takeaway is that while no finish is truly "scratch-proof," PVD is one of the most scratch-resistant options available for consumer and industrial products. Its ultimate toughness, however, depends on both the specific PVD material used and the hardness of the underlying product it is applied to.

How PVD Achieves Its Toughness

The remarkable durability of PVD isn't magic; it's a result of a sophisticated manufacturing process that fundamentally changes the surface properties of an object.

It's a Process, Not a Single Material

PVD stands for Physical Vapor Deposition. It's not a material itself but a method of applying a very thin, very hard coating in a high-tech vacuum chamber.

This process allows for the use of materials that would be impossible to apply otherwise, such as specific ceramics.

Creating a Ceramic Shield

During the PVD process, a solid material—often a ceramic like Titanium Nitride (TiN) or Zirconium Nitride (ZrN)—is vaporized into a plasma of atoms.

This vapor is then deposited onto the product (like a watch case or a faucet), where it bonds to the surface at a molecular level. This creates a dense, hard film that acts like a microscopic layer of armor.

The Importance of Adhesion

Because the coating is bonded atom-by-atom in a vacuum, its adhesion to the substrate (the base material) is incredibly strong.

This prevents the chipping, flaking, or peeling commonly seen with older coating methods like paint or electroplating.

Key Factors That Determine Scratch Resistance

Not all PVD finishes are created equal. The final level of scratch resistance you experience depends on a few critical variables.

The Hardness of the Coating Itself

Different materials can be used in the PVD process, each with a different intrinsic hardness.

Diamond-Like Carbon (DLC), for example, is a type of PVD coating prized for its extreme hardness, closely mimicking the properties of natural diamond. Other materials like Titanium Nitride are also exceptionally hard, far exceeding the hardness of bare stainless steel.

The "Eggshell Effect": Substrate Hardness Matters

This is the most critical factor in real-world durability. A hard PVD coating on a soft substrate can still be damaged.

Imagine pressing a thumbtack into a hard-boiled egg that's sitting on a sponge. The eggshell itself is hard, but because the sponge underneath deforms, the shell will crack.

Similarly, if a hard PVD coating is applied to a soft metal like aluminum, a significant impact can dent the aluminum underneath, causing the rigid PVD layer to crack or flake. A PVD coating on hard stainless steel will be far more resilient.

Understanding the Trade-offs: PVD Is Not Invincible

While PVD is a top-tier finish, it's essential to have realistic expectations. The distinction between "scratch-resistant" and "scratch-proof" is crucial.

Scratch-Resistant vs. Scratch-Proof

PVD will easily resist scuffs from keys, zippers, or being brushed against a wall. However, it can be scratched by materials that are harder than the coating itself.

A sharp piece of quartz or silicon carbide (found in sand, concrete, or sandpaper) or a diamond can scratch even the best PVD finish.

Vulnerability to Deep Gouges

A sharp, heavy impact can damage any material. If an impact is forceful enough to gouge the underlying steel or titanium, it will damage the PVD coating along with it.

The Challenge of Repair

One significant trade-off is repairability. A scratch on a polished stainless steel watch can often be buffed out.

However, a scratch on a PVD coating cannot be spot-repaired. Because the color and finish are integral to the coating itself, the only way to fix a deep scratch is to have the entire part professionally stripped and re-coated, which is often impractical.

Is a PVD Finish Right for You?

Understanding these factors allows you to make an informed decision based on your specific needs and expectations.

- If your primary focus is everyday durability for items like watches, faucets, or tools: PVD offers excellent protection against the vast majority of common scuffs and maintains its appearance far longer than non-coated alternatives.

- If your primary focus is extreme use in abrasive environments: Seek out premium PVD types like DLC applied to a hard substrate (steel or titanium) for the highest level of performance.

- If your primary focus is preserving a flawless aesthetic at all costs: Understand that while PVD is highly resistant, it is not impervious to damage from harder materials or significant impacts.

Ultimately, choosing a PVD-coated product is an excellent way to secure a combination of high-end aesthetics and superior physical durability.

Summary Table:

| Factor | Impact on Scratch Resistance |

|---|---|

| Coating Material | Harder materials like DLC or TiN offer superior resistance. |

| Base Material (Substrate) | A hard substrate (e.g., steel) prevents denting and coating failure. |

| Real-World Use | Resists daily scuffs but can be scratched by harder materials like diamond. |

Need a Durable Finish for Your Products?

PVD coating technology delivers the hardness and longevity your laboratory equipment or consumer goods demand. KINTEK specializes in advanced coating solutions, ensuring your products stand up to daily wear while maintaining a premium look.

Contact our experts today to discuss how PVD can enhance your product's durability and performance.

Visual Guide

Related Products

- Vacuum Dental Porcelain Sintering Furnace

- Silicon Carbide (SIC) Ceramic Sheet Wear-Resistant Engineering Advanced Fine Ceramics

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- Precision Machined Zirconia Ceramic Ball for Engineering Advanced Fine Ceramics

People Also Ask

- What is the main difference between soldering and brazing? Choose the Right Metal Joining Method

- What is the melting point of tungsten in a vacuum? The Real Limit is Sublimation, Not Melting

- Can high fusing porcelain be repaired without distortion? Yes, with the right low-fusing materials and techniques.

- Why are porcelain fired under vacuum? To Eliminate Porosity for Superior Strength & Translucency

- What temperature is porcelain fired at? A Guide to Precise Dental Firing Cycles