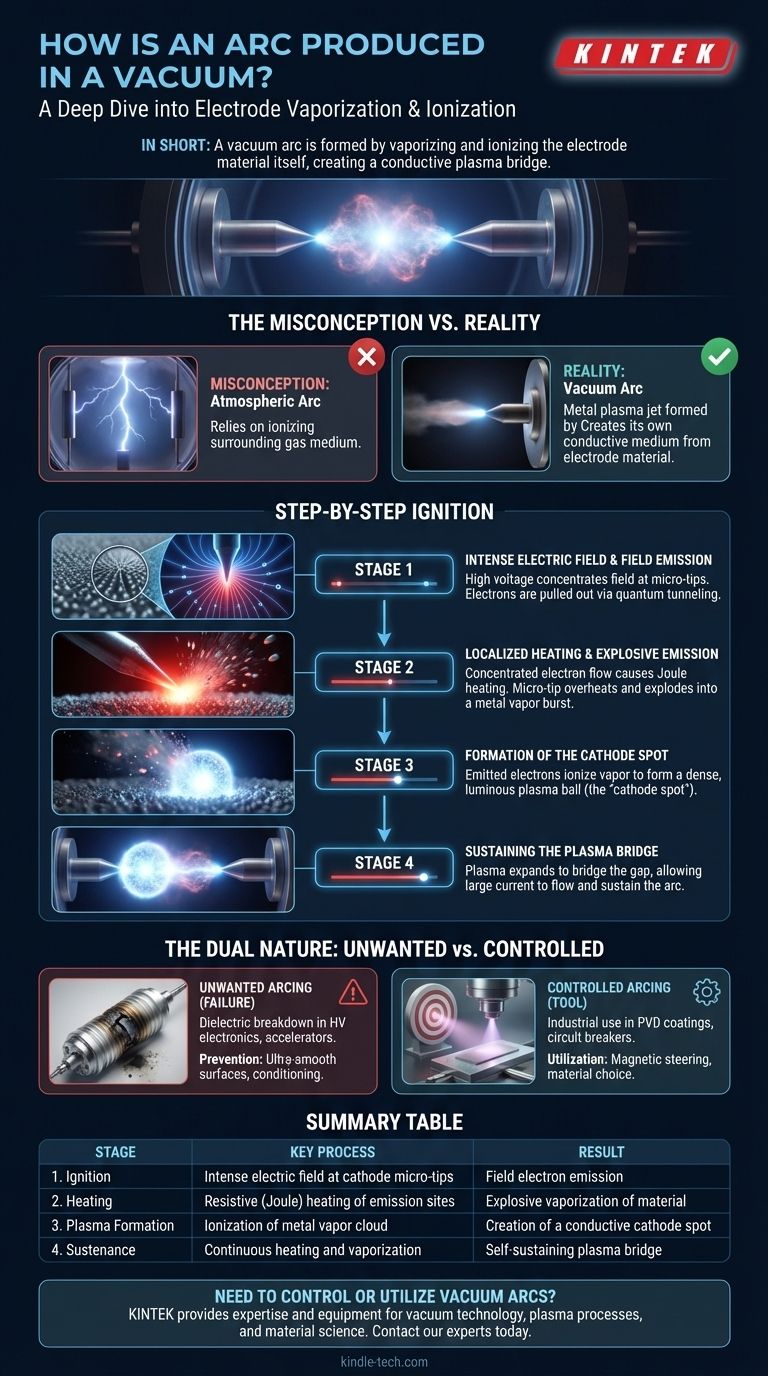

In short, a vacuum arc is produced by vaporizing and ionizing the electrode material itself. Because a vacuum lacks a gaseous medium to ionize, a sufficiently high electric field between two electrodes pulls electrons from the cathode surface, causing microscopic points to explosively overheat and vaporize. This creates a small, dense cloud of metal plasma that acts as a conductive bridge, allowing a large current to flow and sustaining the arc.

A common misconception is that a perfect vacuum cannot conduct electricity. In reality, a vacuum arc bypasses the need for a gas by creating its own conductive medium—a plasma jet formed from the electrode material—triggered by intense electric field emission.

The Misconception: Why a "Perfect" Vacuum Still Arcs

Engineers accustomed to atmospheric conditions often think of arcing as the breakdown of a gas, like air. In a vacuum, this intuition is misleading. The mechanism is entirely different and depends on the electrodes themselves.

The Absence of Gas Ions

In a standard arc (like a lightning bolt), the electric field is strong enough to strip electrons from gas molecules, creating a conductive path of ionized gas. In a high vacuum, there are virtually no gas molecules to ionize, so this process cannot occur.

The Electrodes Become the Fuel

Instead of using a surrounding gas, a vacuum arc uses the solid (or liquid) metal of the electrodes as the source material for its conductive plasma. The arc is, in essence, a self-sustaining jet of vaporized and ionized metal.

The Step-by-Step Ignition of a Vacuum Arc

The formation of a vacuum arc is a rapid, explosive event that occurs in distinct physical stages. It all begins at the surface of the negative electrode, the cathode.

Stage 1: Intense Electric Field and Field Emission

Even highly polished surfaces have microscopic irregularities—tiny points and whiskers. An applied voltage creates an electric field that concentrates intensely at these sharp tips.

When the local electric field becomes extremely high (on the order of billions of volts per meter), it can pull electrons directly out of the cathode material through a quantum mechanical process called field electron emission.

Stage 2: Localized Heating and Explosive Emission

The field-emitted electrons flow in a highly concentrated beam through the microscopic protrusion. This intense current density causes rapid, localized resistive heating (Joule heating).

Within nanoseconds, the tip of the micro-protrusion heats to its boiling point and explodes, releasing a burst of neutral metal vapor and electrons into the vacuum gap. This process is known as explosive electron emission.

Stage 3: Formation of the Cathode Spot

The emitted electrons immediately ionize the newly created cloud of metal vapor, forming a tiny, extremely dense, and luminous ball of plasma. This is the cathode spot.

The cathode spot is the engine of the vacuum arc. It moves rapidly and erratically across the cathode surface, leaving a trail of microscopic craters and continuously providing the vaporized material needed to sustain the arc.

Stage 4: Sustaining the Plasma Bridge

This plasma is an excellent electrical conductor. It expands to bridge the gap between the cathode and the anode, establishing a path for a large arc current to flow.

The flow of this current continues to heat the cathode, creating new cathode spots and ensuring a continuous supply of metal plasma. As long as the power source can supply sufficient current, the arc is self-sustaining.

Understanding the Trade-offs: The Dual Nature of Vacuum Arcs

Understanding this process is critical because vacuum arcing is either a catastrophic failure mode or a highly useful industrial tool, depending on the context.

Unwanted Arcing: The Breakdown Problem

In high-voltage electronics, particle accelerators, and satellite systems, vacuum is used as an insulator. Uncontrolled arcing represents a dielectric breakdown that can cause catastrophic damage to components by short-circuiting the system. Preventing it involves ultra-smooth surface finishing, careful material selection, and a process called "conditioning" to burn off potential emission sites.

Controlled Arcing: The Industrial Tool

Conversely, some technologies are designed to harness this effect. In vacuum interrupters (high-voltage circuit breakers), an arc is intentionally created to interrupt enormous currents. The arc is then quickly extinguished as the contacts separate, safely breaking the circuit.

In arc-PVD (Physical Vapor Deposition), a controlled arc is used to vaporize a cathode material (like titanium) to deposit high-performance hard coatings (like TiN) onto tools and components. The cathode spot is steered with magnetic fields to ensure uniform erosion and coating.

Making the Right Choice for Your Goal

Your approach to vacuum arcing depends entirely on whether you are trying to prevent it or utilize it.

- If your primary focus is preventing breakdown: Your goal is to suppress field emission by designing smooth electrodes, choosing materials with high work functions, and ensuring ultra-clean surfaces free of contaminants.

- If your primary focus is harnessing the arc (e.g., for coatings): Your goal is to promote stable arc ignition and control the cathode spot's movement using specific cathode materials, optimized current levels, and external magnetic fields.

Ultimately, mastering the behavior of a vacuum arc is about controlling the conditions at the cathode surface.

Summary Table:

| Stage | Key Process | Result |

|---|---|---|

| 1. Ignition | Intense electric field at cathode micro-tips | Field electron emission |

| 2. Heating | Resistive (Joule) heating of emission sites | Explosive vaporization of electrode material |

| 3. Plasma Formation | Ionization of metal vapor cloud | Creation of a conductive cathode spot |

| 4. Sustenance | Continuous heating and vaporization | Self-sustaining plasma bridge for arc current |

Need to Control or Utilize Vacuum Arcs in Your Lab?

Whether your goal is to prevent dielectric breakdown in high-voltage systems or to harness a stable arc for precise coating deposition, KINTEK has the expertise and equipment to support your research and production. As a specialist in lab equipment and consumables, we provide solutions for vacuum technology, plasma processes, and material science applications.

Contact our experts today to discuss how we can help you achieve precise control over your vacuum processes and enhance your laboratory's capabilities.

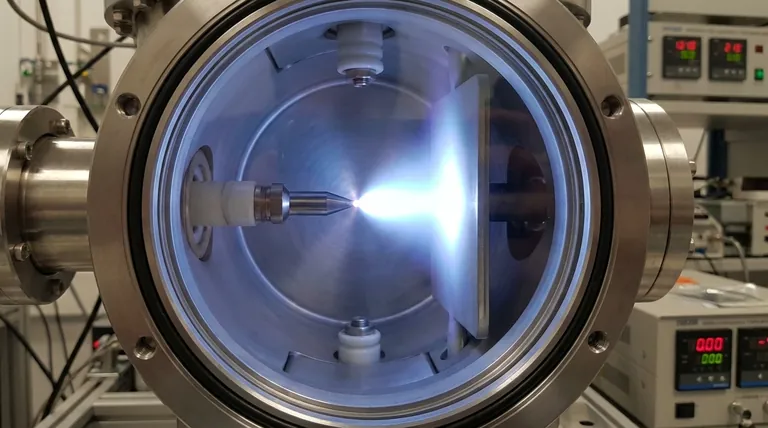

Visual Guide

Related Products

- Vacuum Arc Induction Melting Furnace

- Vacuum Induction Melting Spinning System Arc Melting Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Lab-Scale Vacuum Induction Melting Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What is the vacuum arc remelting process? Producing Ultra-Pure, High-Performance Metal Alloys

- What is the VAR melting process? The Ultimate Guide to Vacuum Arc Remelting

- What is a remelting process? A Guide to High-Purity Metal Refinement

- What is the remelting process? Achieve Ultimate Purity and Performance for High-Strength Alloys

- What is the benefit of vacuum arc remelting? Achieve Superior Metal Purity and Structural Integrity