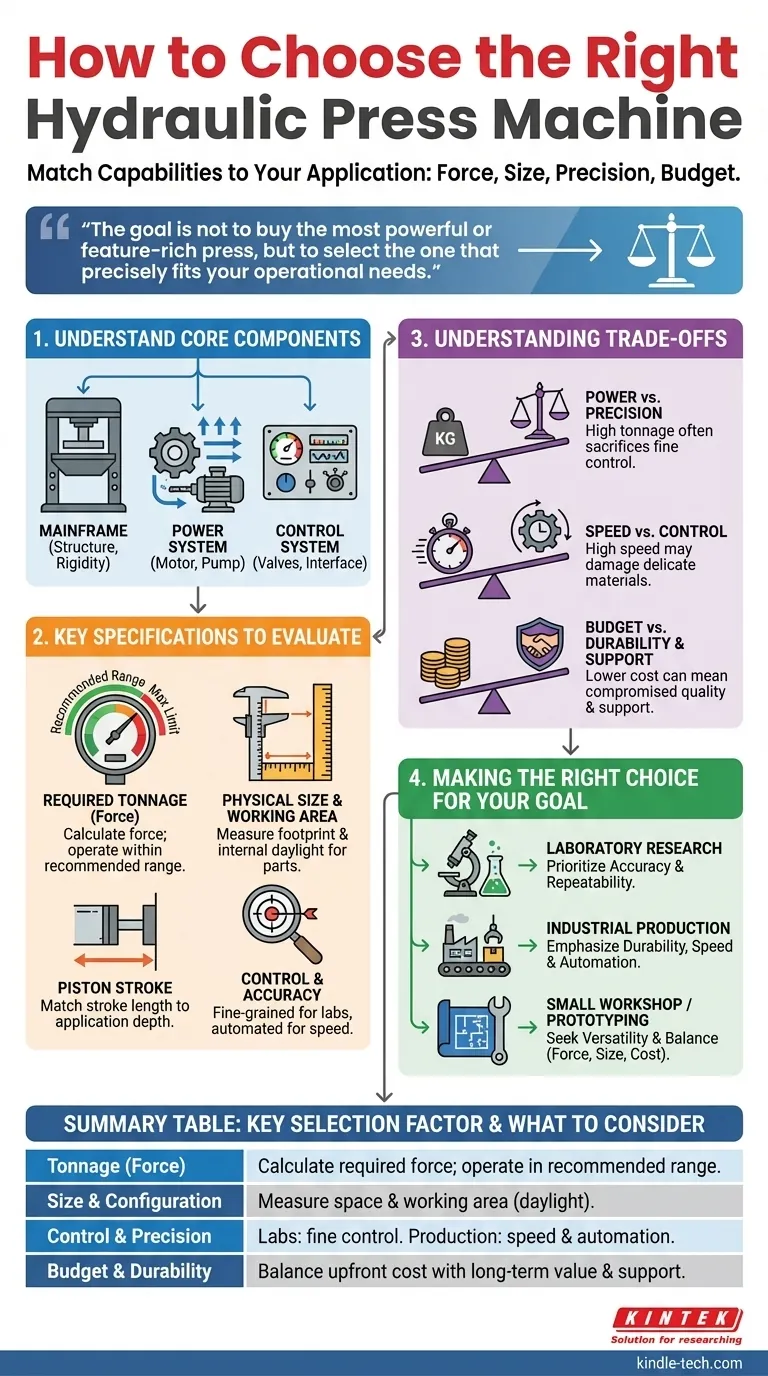

Choosing the right hydraulic press is a process of matching the machine's capabilities directly to your application's specific demands. To make the correct choice, you must evaluate four key areas: the required force (tonnage), the physical size and configuration, the necessary precision of the control system, and your overall budget.

The goal is not to buy the most powerful or feature-rich press, but to select the one that precisely fits your operational needs. A mismatch in force, size, or control can lead to inaccurate results, damaged materials, and a poor return on your investment.

First, Understand the Core Components

A hydraulic press is a system of interconnected parts. Understanding these components helps you evaluate where quality and specific features matter most for your work.

The Mainframe

This is the physical structure of the press. Its design determines the machine's overall rigidity, size, and the type of work it can accommodate.

The frame must be robust enough to handle the maximum rated force without flexing, which would compromise accuracy.

The Power System

This system, typically an electric motor driving a hydraulic pump, generates the fluid pressure that creates the force.

The power system's capacity directly dictates the press's maximum tonnage and operational speed.

The Hydraulic Control System

This is the operational brain of the press. It includes the valves, gauges, and levers (or digital interfaces) that allow the operator to control the application of force.

For laboratory or high-precision work, a highly accurate and repeatable control system is non-negotiable.

Key Specifications to Evaluate

When comparing models, move beyond the brand name and focus on the technical data. These numbers will tell you if the machine is a viable candidate for your tasks.

Required Tonnage (Force)

Tonnage is the maximum compressive force the press can generate. This is the single most important specification.

Calculate the force your application requires and choose a press where this falls within the recommended power range, not the absolute maximum. Consistently operating at the absolute limit will drastically shorten the machine's lifespan.

Physical Size and Working Area

You must consider both the machine's external footprint and its internal working dimensions.

Measure your available floor or bench space to ensure the press will fit. More importantly, verify that the press's internal working area—often called "daylight"—is large enough for your dies, molds, or workpieces.

Piston Stroke

The stroke is the maximum distance the piston can travel from its fully retracted to its fully extended position.

A short stroke may be fine for simple compression tasks, but applications requiring deeper pressing or forming will necessitate a longer stroke.

Control and Accuracy

The level of control you need is dictated by your application. Some processes only require raw force, while others demand immense precision.

For lab work or delicate materials, look for presses with fine-grained pressure control and accurate gauges. For industrial production, you may prioritize speed and automated controls for repeatability.

Understanding the Trade-offs

Selecting a hydraulic press involves balancing competing characteristics. Being aware of these trade-offs is critical for making an informed decision.

Power vs. Precision

Extremely high-tonnage presses are built for raw power. They often sacrifice the fine control and sensitivity needed for delicate laboratory or research applications.

Speed vs. Control

Presses designed for high-speed industrial production may apply force too quickly for materials that need to be compressed slowly and deliberately to avoid fractures or defects.

Budget vs. Durability & Support

A lower upfront cost can be appealing, but it may come at the expense of build quality, component durability, and the availability of technical support or warranties.

For any business or critical research function, reliability and manufacturer support often provide more long-term value than a lower initial price.

Making the Right Choice for Your Goal

Your primary objective should guide your final selection.

- If your primary focus is laboratory research: Prioritize a press with exceptional pressure accuracy, repeatability, and a clear, precise control system.

- If your primary focus is industrial production: Emphasize durability, operational speed, and the potential for automation to ensure consistent output.

- If your primary focus is a small workshop or prototyping: Seek a versatile, reliable benchtop model that offers a good balance between force, size, and cost.

Ultimately, a well-chosen hydraulic press becomes a reliable tool that delivers consistent and accurate results for years to come.

Summary Table:

| Key Selection Factor | What to Consider |

|---|---|

| Tonnage (Force) | Calculate required force; choose a press operating within its recommended range, not at its maximum limit. |

| Size & Configuration | Measure available space and ensure the working area (daylight) fits your dies, molds, or workpieces. |

| Control & Precision | For labs: prioritize fine-grained pressure control. For production: consider speed and automation. |

| Budget & Durability | Balance upfront cost with long-term value from build quality, reliability, and manufacturer support. |

Need a hydraulic press that perfectly fits your application?

At KINTEK, we specialize in providing high-quality lab equipment, including hydraulic presses tailored for both precise laboratory research and demanding industrial production. Our experts will help you navigate the specifications to find a machine that delivers the right balance of force, control, and durability for your specific needs—ensuring accurate results and a strong return on your investment.

Contact our team today for a personalized consultation and discover the KINTEK difference in reliability and support.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- What is the difference between KBr method and ATR method? Choose the Right FTIR Technique for Your Lab

- What are benefits of hydraulic press? High Force, Precision Control, and Cost-Effectiveness

- What temperature should oil be in hydraulic press? Maintain 120°F-140°F for Peak Performance

- What are the advantages of metal pressing? Unlock High-Speed, Low-Cost Mass Production

- How is a laboratory hydraulic press utilized in double-layer solid-state battery assembly? Key Pre-pressing Guide

- How many tons can a hydraulic press produce? From 1 to 50,000+ Tons Explained

- How are hydraulic presses used for forging? Achieve Superior Control for Complex Metal Components

- What are the safety precautions required when using the hydraulic press? Ensure Operator and Machine Protection