Calculating the capacity of a hydraulic press is a straightforward process based on a core principle of physics. The maximum force, or tonnage, is determined by multiplying the hydraulic system's maximum pressure by the surface area of the cylinder's piston. This fundamental relationship allows you to understand the absolute power your machine can deliver.

The core principle is this: A hydraulic press doesn't create energy; it converts hydraulic pressure into immense mechanical force. Understanding the two key variables—the pump's pressure limit and the cylinder's physical size—is the key to accurately calculating its capacity.

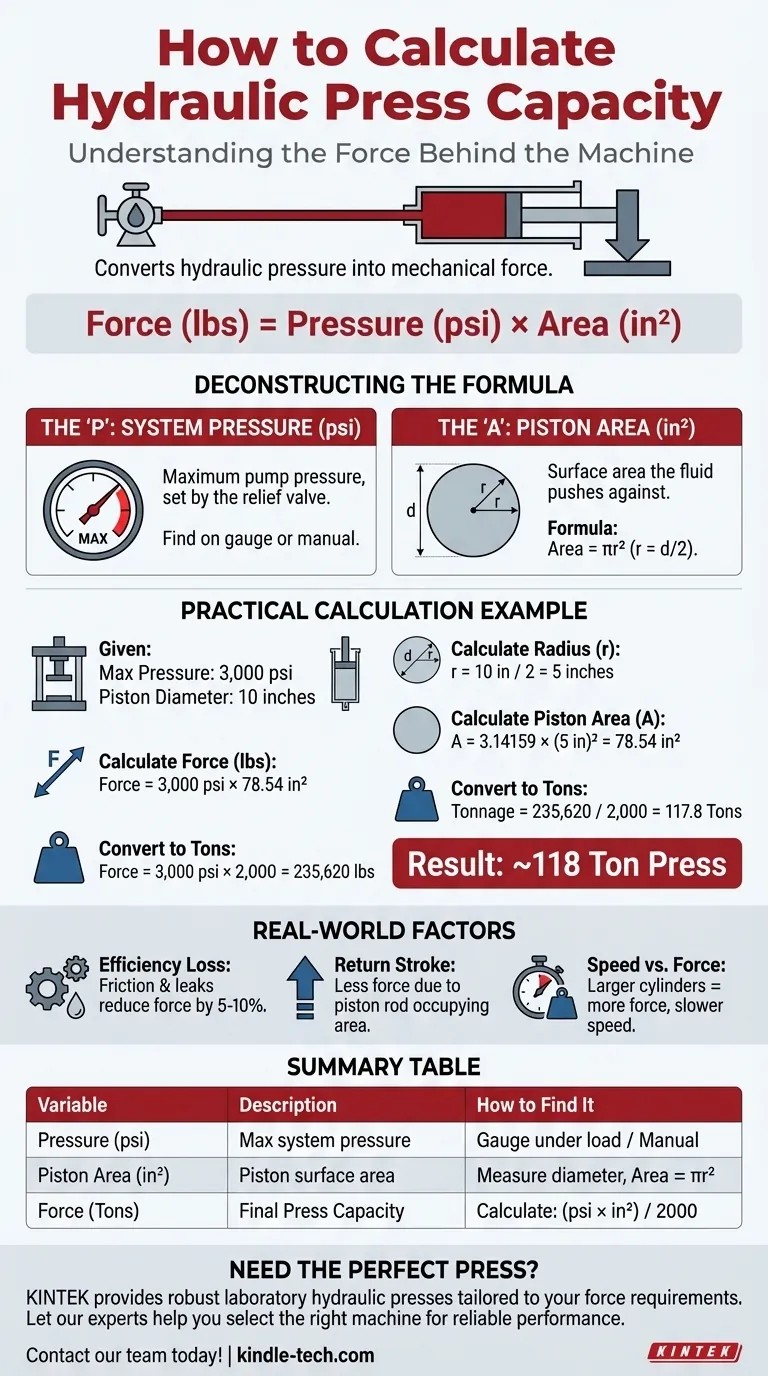

Deconstructing the Capacity Formula

The formula for hydraulic press force is a direct application of Pascal's Law. It is simple, yet every component is critical for an accurate result. The formula is:

Force (lbs) = Pressure (psi) × Area (in²)

To get the final tonnage, you simply divide the force in pounds by 2,000.

The "P": System Pressure (psi)

This value represents the maximum pressure the hydraulic power system can generate.

It is not the pressure at any given moment but is instead set by the system's main pressure relief valve. This valve acts as a safety, preventing the system from exceeding its designed limits.

You can typically find this value on the machine's pressure gauge when it is under maximum load, or listed in the manufacturer's technical manual as "Max System Pressure."

The "A": Piston Area (in²)

This is the surface area of the face of the piston inside the main cylinder, which is the surface the hydraulic fluid pushes against.

Because the piston is circular, you use the standard formula for the area of a circle: Area = πr², where 'r' is the radius of the piston.

To find the radius, measure the diameter of the piston (not the entire cylinder housing) and divide it by two. It is critical to use the internal piston diameter for this calculation.

Putting It Together: A Practical Calculation

Let's walk through an example to make this concrete.

- Given: A press with a maximum system pressure of 3,000 psi.

- Given: A main cylinder with a piston diameter of 10 inches.

-

Calculate the Radius:

- Radius = Diameter / 2

- Radius = 10 in / 2 = 5 inches

-

Calculate the Piston Area:

- Area = π × r²

- Area = 3.14159 × (5 in)² = 78.54 in²

-

Calculate the Force in Pounds:

- Force = Pressure × Area

- Force = 3,000 psi × 78.54 in² = 235,620 lbs

-

Convert Force to Tons:

- Tonnage = Force (lbs) / 2,000

- Tonnage = 235,620 / 2,000 = 117.8 Tons

This press would be rated as a 118-ton press.

Understanding the Trade-offs and Real-World Factors

The calculation gives you a precise theoretical maximum, but several real-world factors can influence the actual performance of the machine.

Theoretical vs. Actual Tonnage

The formula provides the maximum theoretical force. In practice, you should account for a small loss in efficiency.

Friction from the cylinder seals and minor internal hydraulic leaks can reduce the actual force delivered at the ram by 5% to 10%. For critical applications, it's wise to factor in this efficiency loss.

The Impact of Return Stroke

The calculation above is for the pressing (downward) stroke. The return (upward) stroke generates significantly less force.

This is because on the return stroke, fluid pushes on the other side of the piston, where the surface area is reduced by the presence of the piston rod. This is known as the annulus area.

Speed vs. Force

There is an inherent trade-off between the force a press can generate and how fast it can operate.

A larger diameter cylinder produces more tonnage at the same pressure, but it also requires a greater volume of hydraulic fluid to move. This means, for a given pump flow rate, a higher tonnage press will often move more slowly than a lower tonnage one.

Making an Accurate Assessment

Use this understanding to evaluate the machine based on your specific goal.

- If your primary focus is verifying a machine's stated tonnage: Find the maximum system pressure from the manual and physically measure the cylinder's piston diameter. These two numbers are all you need to confirm its capacity.

- If your primary focus is selecting a press for a specific job: Determine the force your application requires first, then add a safety margin (e.g., 20%). Use this target tonnage to find a machine with the right combination of pressure and piston area.

- If your primary focus is troubleshooting low performance: Check the pressure gauge while the machine is under load. If the pressure cannot reach the specified maximum, the problem lies within the hydraulic power system (e.g., the pump or relief valve), not the cylinder itself.

This fundamental calculation empowers you to accurately assess, select, and troubleshoot any hydraulic press system.

Summary Table:

| Key Variable | Description | How to Find It |

|---|---|---|

| Pressure (psi) | Maximum system pressure from the hydraulic pump. | Check the pressure gauge under load or the manufacturer's manual (main relief valve setting). |

| Piston Area (in²) | Surface area of the cylinder's piston. | Measure piston diameter, calculate radius, then use Area = πr². |

| Force (Tons) | Final press capacity. | Force (lbs) = Pressure (psi) × Area (in²); Tonnage = Force (lbs) / 2000 |

Need a Hydraulic Press with the Perfect Tonnage for Your Application?

Selecting the right press is critical for your project's success and safety. KINTEK specializes in providing robust laboratory equipment, including hydraulic presses tailored to your specific force requirements. Our experts can help you analyze your needs to ensure you get a machine that delivers reliable performance.

Contact our team today for a personalized consultation and discover the KINTEK difference in lab equipment solutions!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Manual Lab Heat Press

People Also Ask

- What is the advantage of KBr? Unmatched IR Transparency for Precise Spectroscopy

- What is the use of KBr? Master Sample Prep for Accurate IR Spectroscopy

- What is the pressed powder pellet method? A Guide to Accurate FTIR Sample Preparation

- Why use KBr for IR? Achieve Clear, Unobstructed Spectra for Solid Samples

- Why are KBr pellets used in FTIR? Achieve Clear, Accurate Solid Sample Analysis