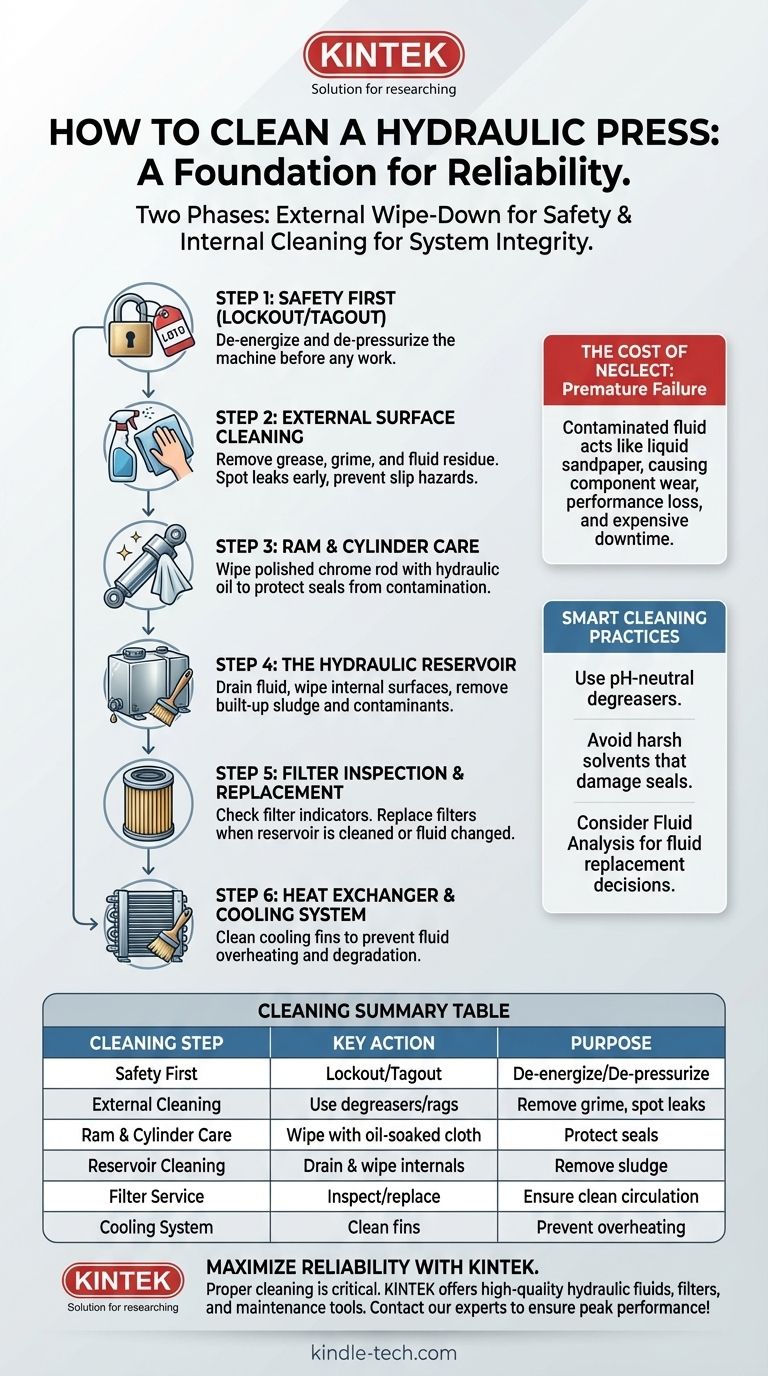

Cleaning a hydraulic press is a foundational maintenance task that extends far beyond simple aesthetics. A proper cleaning procedure involves two distinct phases: a thorough external wipe-down to ensure safety and enable inspection, and a more critical internal system cleaning focused on preserving the integrity of the hydraulic fluid and its components. The process always begins with a strict lockout/tagout procedure to ensure the machine is de-energized and de-pressurized.

The true purpose of cleaning a hydraulic press is not just to make it look good, but to prevent contamination of the hydraulic system. Contaminants are the primary cause of component wear and failure, making a disciplined cleaning regimen a direct investment in the machine's reliability, precision, and operational lifespan.

The Two Pillars of Hydraulic Press Cleaning: External and Internal

A comprehensive cleaning plan addresses both the outside of the machine and its critical inner workings. One enables the other; a clean exterior makes it easier to spot the leaks and issues that signal a need for internal attention.

Step 1: Safety First (Lockout/Tagout)

Before any work begins, the machine must be made safe. This is non-negotiable.

This involves a full lockout/tagout (LOTO) procedure, electrically isolating the press from its power source. Crucially, you must also safely release any stored hydraulic pressure according to the manufacturer's specific instructions.

Step 2: External Surface Cleaning

The goal here is to remove all grease, grime, and hydraulic fluid residue from the press frame, bed, and control panels.

Use industrial-grade degreasers and lint-free rags. A clean exterior is not for show; it allows operators to immediately spot new hydraulic leaks, which are early indicators of seal or hose failure. It also prevents slip-and-fall hazards.

Step 3: Ram and Cylinder Maintenance

The polished chrome rod of the hydraulic ram is a critical surface. It must be kept impeccably clean.

Wipe the ram with a clean, soft cloth lightly soaked in hydraulic oil. Any dirt or grit adhering to the ram can be pulled into the cylinder on the retraction stroke, damaging the rod seals and introducing contaminants directly into the hydraulic system.

Step 4: The Heart of the System: The Hydraulic Reservoir

The reservoir (or tank) is where sludge, water, and solid contaminants accumulate over time. Periodic cleaning is essential for system health.

This process involves draining the hydraulic fluid, physically wiping the internal surfaces of the tank clean, and inspecting for any sediment. This is the single most effective task for removing built-up contaminants from the entire system.

Step 5: Filter Inspection and Replacement

Your press has several filters (e.g., suction, pressure, return line) designed to capture contaminants. Cleaning is the perfect time to service them.

Check the filter indicators, if equipped. Many maintenance schedules call for replacing filters whenever the reservoir is cleaned or the fluid is changed, ensuring the new or cleaned fluid starts in a pristine environment.

Step 6: Heat Exchanger and Cooling System

The press's heat exchanger (either air-cooled or water-cooled) is vital for regulating fluid temperature. Its efficiency depends on being clean.

For air-cooled units, use compressed air or a soft brush to remove dust and debris from the cooling fins. Clogged fins will cause the hydraulic fluid to overheat, leading to premature fluid degradation and component damage.

Understanding the Trade-offs: Cleaning vs. Contamination

Failing to maintain a clean system is not a cost-saving measure; it is a direct path to expensive and unplanned downtime.

The Cost of Neglect: Premature Component Failure

Contaminated hydraulic fluid is highly abrasive. It acts like liquid sandpaper inside your system's pumps, valves, and actuators.

This contamination is the leading cause of premature component wear, resulting in diminished performance, loss of precision, and eventual catastrophic failure. It is far cheaper to clean a reservoir than to replace a hydraulic pump.

The Risk of Improper Cleaning Agents

Be mindful of the chemicals you use. Harsh solvents or cleaners not designed for industrial machinery can have unintended consequences.

They can damage seals and hoses, causing them to become brittle and leak. They can also strip paint, exposing the machine's frame to corrosion. Always use a pH-neutral degreaser or a product approved by the press manufacturer.

When to Clean vs. When to Replace Fluid

Cleaning the reservoir is not a substitute for changing degraded fluid. If the hydraulic fluid itself has broken down from heat or is heavily saturated with water, it must be replaced.

The only way to know for sure is through regular fluid analysis. Sending a sample to a lab can tell you the particle count, water content, and chemical composition, providing a clear verdict on whether to filter the existing fluid or replace it entirely.

Tailoring Your Cleaning Strategy

Apply these principles based on your specific operational goals. A proactive approach is always superior to a reactive one.

- If your primary focus is routine preventative maintenance: Center your efforts on weekly external wipe-downs and visual inspections, scheduling a full reservoir cleaning annually or as recommended by the manufacturer.

- If you are experiencing performance issues (e.g., slow operation, pressure drops): Your "cleaning" should immediately escalate to inspecting filters and taking a hydraulic fluid sample for professional analysis to diagnose the root cause.

- If your primary focus is safety and compliance: Integrate the LOTO procedure and external cleaning into a documented daily or weekly checklist for operators.

Ultimately, viewing cleaning as an integral part of your mechanical maintenance strategy transforms it from a chore into a powerful tool for ensuring machine reliability.

Summary Table:

| Cleaning Step | Key Action | Purpose |

|---|---|---|

| Safety First | Lockout/Tagout (LOTO) | De-energize and de-pressurize the machine for safe work. |

| External Cleaning | Use degreasers and lint-free rags | Remove grime and spot leaks early; prevent slip hazards. |

| Ram & Cylinder Care | Wipe with oil-soaked cloth | Protect rod seals and prevent internal contamination. |

| Reservoir Cleaning | Drain fluid and wipe internal surfaces | Remove sludge and contaminants from the hydraulic system's core. |

| Filter Service | Inspect and replace filters | Ensure clean fluid circulation and capture particles. |

| Cooling System | Clean heat exchanger fins | Prevent fluid overheating and degradation. |

Maximize the reliability and lifespan of your hydraulic press with KINTEK's support. Proper cleaning is critical, but having the right equipment and consumables makes all the difference. KINTEK specializes in lab and industrial equipment, offering high-quality hydraulic fluids, filters, and maintenance tools tailored to your needs. Don't let contamination lead to costly downtime—contact our experts today to ensure your press operates at peak performance!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Heated Hydraulic Press Machine with Heated Plates Split Manual Laboratory Hot Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Laboratory Manual Hydraulic Pellet Press for Lab Use

People Also Ask

- What are the applications of a hydraulic press? From Metal Shaping to Material Testing

- What are the examples where hydraulic press is applied? From Industrial Forging to Lab Sample Prep

- What is the function of a laboratory hydraulic press in the preparation of LAGP solid electrolyte substrates?

- What role does a uniaxial hydraulic press play in the fabrication of NaSICON ceramic cylinders? Pre-forming Excellence

- How many pounds of force does a hydraulic press have? Find Your Ideal Tonnage for Any Application

- Press forging vs. hammer forging: Which is right for your metal forming needs?

- What is the purpose of using a laboratory hydraulic press for pre-pressure? Enhance Sintering Precision & Density

- Importance of Precision Hydraulic Pressing in TRISO Fuel Pellet Fabrication: Ensure Integrity and Performance