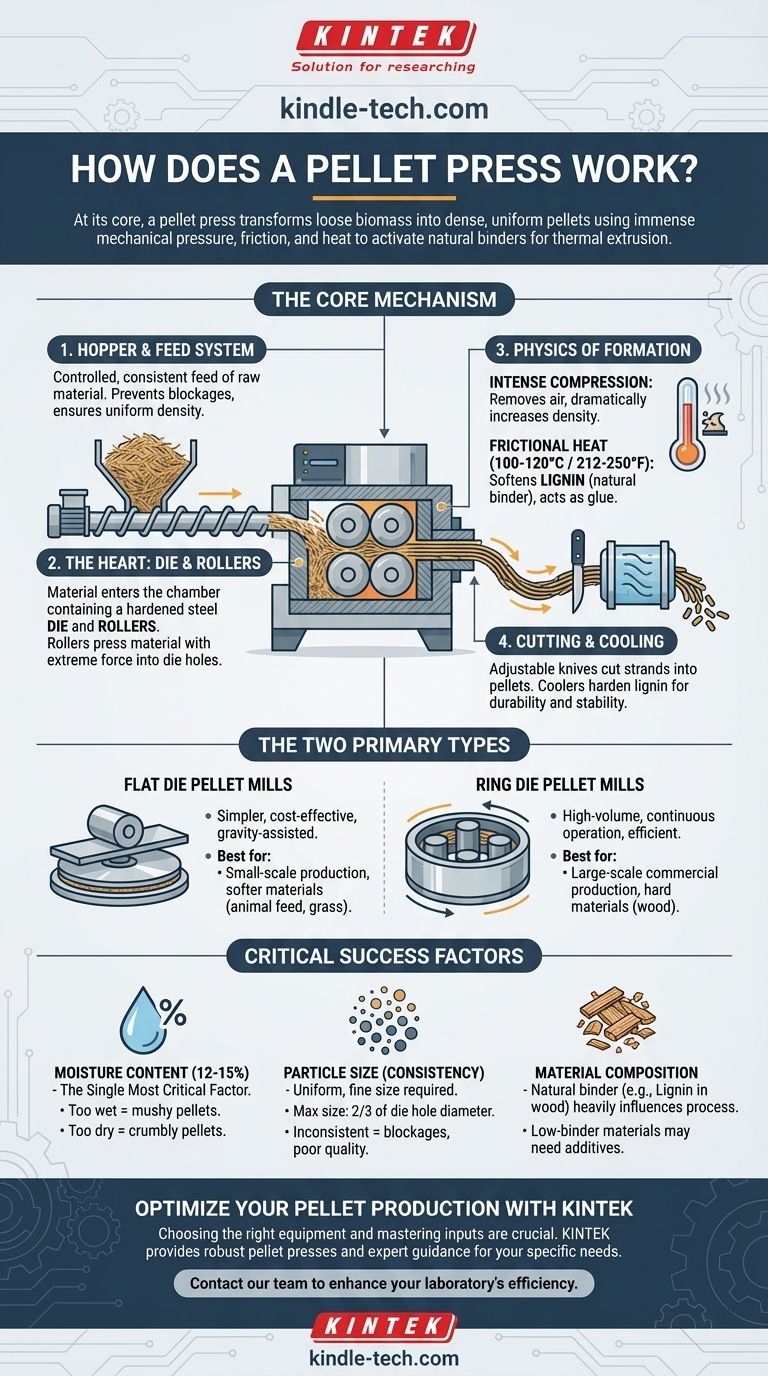

At its core, a pellet press, also known as a pellet mill, is a machine that transforms loose, low-density biomass or other materials into dense, uniform pellets. It achieves this by using immense mechanical pressure to force the raw material through the holes of a hardened steel die. The friction generated during this process creates intense heat, which activates natural binders within the material, causing it to fuse together as it is extruded.

The critical insight is that pelletizing is not just simple compression. It is a process of thermal extrusion, where the combination of intense pressure, frictional heat, and the material's own natural binders work together to create a dense and durable final product.

The Core Mechanism: From Raw Material to Finished Pellet

Understanding the journey of the material through the press reveals how the process works. Each stage plays a critical role in the final quality of the pellet.

The Hopper and Feed System

All material starts in the hopper. From there, a controlled feeder, typically an auger screw, delivers a consistent and uniform flow of the raw material into the pelleting chamber. This consistent feed rate is essential for preventing blockages and ensuring uniform pellet density.

The Heart of the Machine: The Die and Rollers

This is where the transformation occurs. The material enters a chamber containing two primary components: a die and one or more rollers.

The die is a thick, circular piece of hardened steel perforated with numerous holes or channels. The rollers press against the inner surface of the die with extreme force. As the rollers turn, they continuously force the raw material into and through the holes in the die.

The Physics of Pellet Formation

As the material is forced through the die holes, two key things happen. First, it is intensely compressed, which removes air and dramatically increases its density.

Second, the immense friction between the material and the die walls generates significant heat, often reaching 100-120°C (212-250°F). This heat softens the lignin, a natural polymer found in wood and other plant matter, which then acts as a natural glue, binding the particles together.

Cutting and Cooling

As the newly formed, hot, and continuous strands of material are extruded from the other side of the die, a set of adjustable knives cuts them to a predetermined length, creating individual pellets.

These hot pellets are then sent to a cooler. This final step is crucial to harden the lignin and ensure the pellets become rigid, durable, and stable for storage and transport.

The Two Primary Types of Pellet Presses

While the principle remains the same, pellet presses are typically built in two distinct configurations, each suited for different scales and materials.

Flat Die Pellet Mills

In a flat die mill, the die is a horizontal, flat disc. Rollers are mounted above the die and rotate, forcing the material down through the holes. Gravity assists in the feeding process.

These machines are generally simpler in construction, easier to maintain, and less expensive. They are the standard choice for small-scale production, home use, and processing softer materials like animal feed or grass.

Ring Die Pellet Mills

In a ring die mill, the die is a vertical ring that rotates at high speed around stationary rollers. Centrifugal force throws the material outward against the inner surface of the rotating die, where the rollers force it through the die holes.

Ring die mills are built for high-volume, continuous operation and are more effective at pelleting hard materials like wood. They are the industry standard for large-scale commercial and industrial production of fuel pellets.

Understanding the Critical Success Factors

Simply owning a pellet press is not enough to produce quality pellets. The condition of the raw material is arguably more important than the machine itself.

Moisture Content: The Make-or-Break Variable

This is the single most critical factor. The ideal moisture content for most biomass is between 12% and 15%.

If the material is too wet, the steam produced in the die will prevent proper compression, resulting in soft, mushy pellets. If it's too dry, there isn't enough moisture to help activate the binders, and the pellets will be crumbly and fall apart.

Particle Size: Consistency is Key

The raw material must be ground to a consistent and fine particle size before entering the pellet mill. A general rule is that the maximum particle size should be no larger than two-thirds the diameter of the die holes. Inconsistent or oversized particles lead to blockages and poor pellet quality.

Material Composition and Binders

The type and amount of natural binder in the material heavily influence the process. Wood is rich in lignin, making it ideal. Materials with less natural binder, like some agricultural residues, may require the addition of a binding agent (e.g., starch or molasses) to form a durable pellet.

Making the Right Choice for Your Goal

Your objective determines the right technology and focus. Use these principles to guide your decision-making.

- If your primary focus is small-scale production or processing soft feed: A flat die pellet mill offers the best balance of cost, simplicity, and performance for your needs.

- If your primary focus is large-scale, commercial fuel pellet production: A ring die pellet mill is the required standard for its efficiency, durability, and high throughput.

- If you are troubleshooting poor pellet quality: Always investigate your material's moisture content and particle size first, as these are the most common causes of failure.

Mastering pellet production is a matter of precisely controlling the inputs to achieve a predictable output.

Summary Table:

| Pellet Press Type | Best For | Key Characteristics |

|---|---|---|

| Flat Die Mill | Small-scale production, animal feed, softer materials | Simpler, easier maintenance, cost-effective, gravity-assisted feed |

| Ring Die Mill | Large-scale commercial fuel pellet production | High-volume, continuous operation, efficient for hard materials like wood |

Ready to optimize your pellet production?

Whether you're scaling up a commercial operation or starting a small-scale project, choosing the right equipment is crucial for success. KINTEK specializes in providing robust and efficient lab equipment and consumables, including pellet presses designed to meet your specific material and throughput requirements.

Our experts can help you select the perfect mill and provide guidance on material preparation to ensure you produce high-quality, durable pellets every time.

Contact our team today to discuss your pelleting needs and discover how KINTEK can enhance your laboratory's efficiency and output.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

- Automatic Laboratory Hydraulic Pellet Press Machine for Lab Use

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- kbr pellet press 2t

People Also Ask

- How much pressure should a hydraulic press have? Focus on Tonnage for Your Application

- What is the role of a laboratory hydraulic press in preparing MXene films? Essential Sample Prep for Material Science

- What is the effect of pressure and temperature on the hydraulic fluid? Optimize Your System's Performance

- What is the purpose of using a laboratory hydraulic press for LGVO synthesis? Achieve High-Purity Solid Electrolytes

- What is the primary function of a hydraulic press in SiC/Al-Zn-Mg-Cu extrusion? Mastering Material Deformation

- What is the primary objective of applying 200 MPa of pressure for NASICON pellets? Achieve Maximum Electrolyte Density

- Why is a hydraulic pellet press used for FTIR? Transform Nanofillers into Clear Data

- What products are made with a hydraulic press? From Car Parts to Cosmetics, Shaping Modern Manufacturing