In essence, a rotary calciner is a high-temperature industrial furnace housed within a rotating cylinder. It works by continuously tumbling bulk solid materials at a controlled speed down a slight incline while applying precise heat, which drives a physical or chemical transformation in the material. This process is used for tasks ranging from removing moisture to inducing complex chemical reactions.

A rotary calciner's unique value lies in its ability to deliver exceptionally uniform thermal processing to every particle of a bulk solid. By combining controlled heat, constant motion, and a managed internal atmosphere, it achieves consistent product quality at an industrial scale that static furnaces cannot match.

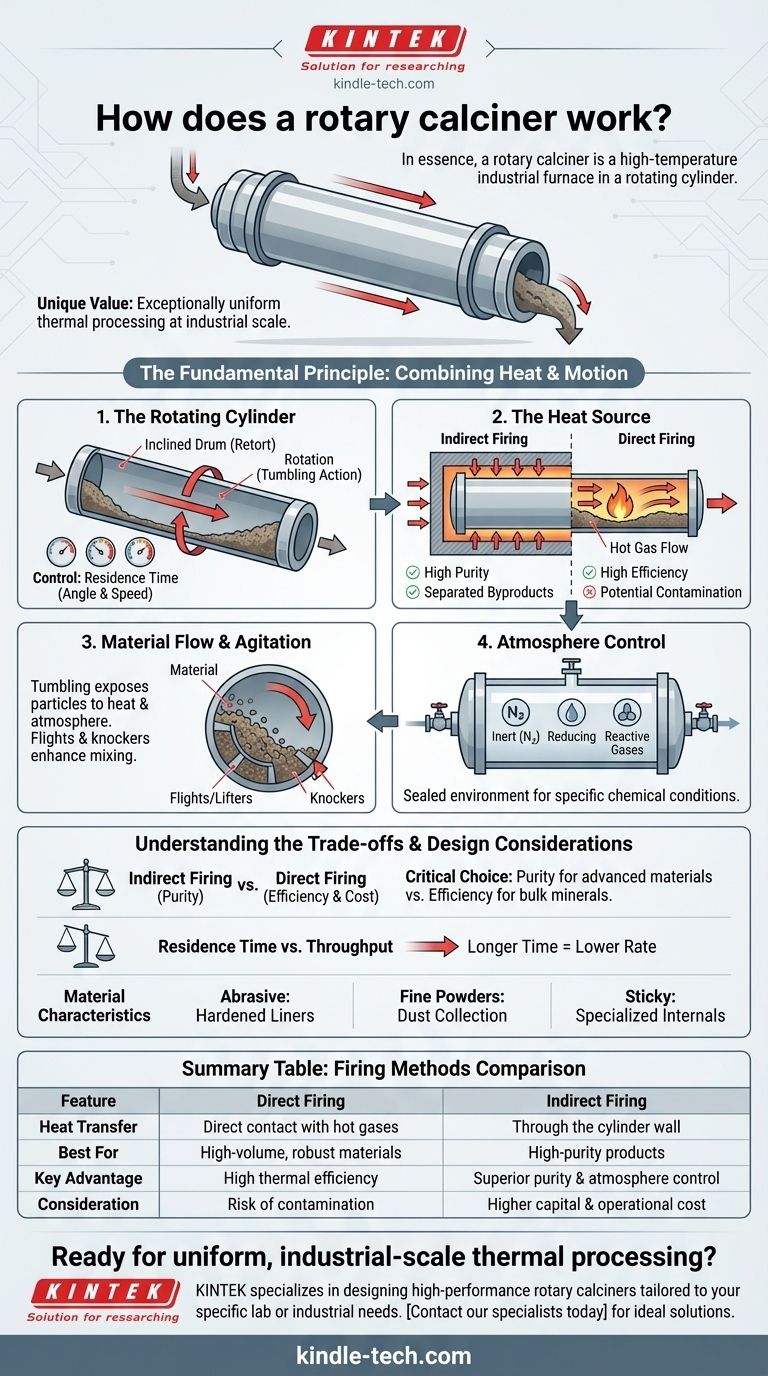

The Fundamental Principle: Combining Heat and Motion

At its core, a rotary calciner is an elegant solution to the challenge of heating a large volume of solid material evenly. It accomplishes this through the orchestrated interplay of several key operational principles.

The Rotating Cylinder

The heart of the system is a cylindrical drum, or "retort," that is slightly inclined. As the drum rotates, material fed into the higher end tumbles and cascades, moving gradually toward the discharge end.

The angle of inclination and the rotational speed are critical process parameters. They work together to dictate the residence time—the total duration the material spends inside the calciner. Adjusting these allows operators to precisely control the extent of the thermal treatment.

The Heat Source

Heat can be applied in one of two fundamental ways, a choice that defines the calciner's capabilities.

- Indirect Firing: The rotating cylinder is enclosed within a furnace. Heat is applied to the outside of the cylinder, which then radiates heat inward to the material. This keeps the combustion byproducts separate from the process material, ensuring high purity.

- Direct Firing: A flame or hot gas is passed directly through the inside of the cylinder, coming into direct contact with the material. This method is more thermally efficient but risks product contamination from the heating gas.

Material Flow and Agitation

The tumbling action is the key to uniform processing. As the material bed is lifted by the rotating wall and cascades back down, new particles are constantly exposed to the heat source and the internal atmosphere.

To enhance this mixing, internal structures called flights or lifters can be added to lift the material higher before it tumbles. For sticky materials, bed disturbers or external "knockers" can be used to prevent buildup on the cylinder wall.

Atmosphere Control

Many calcination processes require a specific chemical environment. Rotary calciners excel at this because they can be sealed at both the feed and discharge ends.

These seals allow for the introduction of a controlled atmosphere. This could be an inert atmosphere (like nitrogen) to prevent oxidation, a reducing atmosphere to remove oxygen from a compound, or a specific reactive gas to facilitate a chemical change.

Understanding the Trade-offs and Design Considerations

While powerful, the rotary calciner is not a universal solution. Selecting and designing one requires a clear understanding of its inherent trade-offs.

Indirect vs. Direct Firing

This is the most critical decision. Indirect firing is essential for high-purity products like battery materials or pharmaceuticals, where any contamination is unacceptable. However, it is less energy-efficient and often has a higher capital cost due to the complex furnace and alloy retort required.

Direct firing is a more economical choice for high-volume, lower-value materials like minerals or aggregates, where thermal efficiency is paramount and direct contact with combustion gas is not detrimental to the final product.

Residence Time and Throughput

There is an inverse relationship between residence time and throughput. A long residence time, required for slow reactions, will result in lower throughput for a given machine size. The calciner must be sized appropriately to meet both the required heating duration and the desired production rate.

Material Characteristics

The physical properties of the feed material heavily influence design.

- Abrasive materials require hardened or replaceable liners to prevent wear on the drum.

- Fine powders can become entrained in the process gas, requiring downstream dust collection systems like baghouses or cyclones.

- Sticky or agglomerating materials may need specialized internals or knockers to ensure continuous flow and prevent clogging.

Making the Right Choice for Your Goal

The decision to use a rotary calciner, and how to configure it, depends entirely on your material and process objectives.

- If your primary focus is material purity and precise atmosphere control: An indirect-fired rotary calciner is the definitive choice for applications like advanced catalysts, battery components, or specialty chemicals.

- If your primary focus is high-throughput and thermal efficiency for robust materials: A direct-fired rotary calciner provides an economical and effective solution for processing minerals, clays, and certain waste streams.

- If your material is extremely fragile or requires a static environment: The tumbling action may be too aggressive, and alternative technologies like a tunnel kiln or belt furnace may be more suitable.

Understanding these core principles empowers you to select the optimal thermal processing technology for your specific application.

Summary Table:

| Feature | Direct Firing | Indirect Firing |

|---|---|---|

| Heat Transfer | Direct contact with hot gases | Through the cylinder wall |

| Best For | High-volume, robust materials (e.g., minerals) | High-purity products (e.g., battery materials) |

| Key Advantage | High thermal efficiency | Superior product purity & atmosphere control |

| Consideration | Risk of product contamination | Higher capital and operational cost |

Ready to achieve uniform, industrial-scale thermal processing for your materials?

KINTEK specializes in designing and supplying high-performance rotary calciners tailored to your specific lab or industrial needs. Whether you require the purity of indirect firing for advanced materials or the efficiency of direct firing for mineral processing, our experts will help you select the ideal solution.

Contact our thermal processing specialists today to discuss how a KINTEK rotary calciner can enhance your product quality and throughput.

Visual Guide

Related Products

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What are the heating sources for pyrolysis? Direct vs. Indirect Methods for Optimal Product Yield

- What is the purpose of a fluidized bed? Achieve Superior Heat Transfer and Process Efficiency

- What are the advantages of a rotary kiln? Achieve Superior High-Temperature Processing

- What is microwave pyrolysis of polypropylene? An Advanced Chemical Recycling Method

- What is the process of thermal pyrolysis? A Step-by-Step Guide to Chemical Recycling

- How much energy is needed for pyrolysis? Achieve a Self-Sustaining Operation

- How does the calcination process work? Master Thermal Decomposition for Material Purification

- What is the chemical composition of pyrolysis gas? A Guide to Its Variable Fuel Components