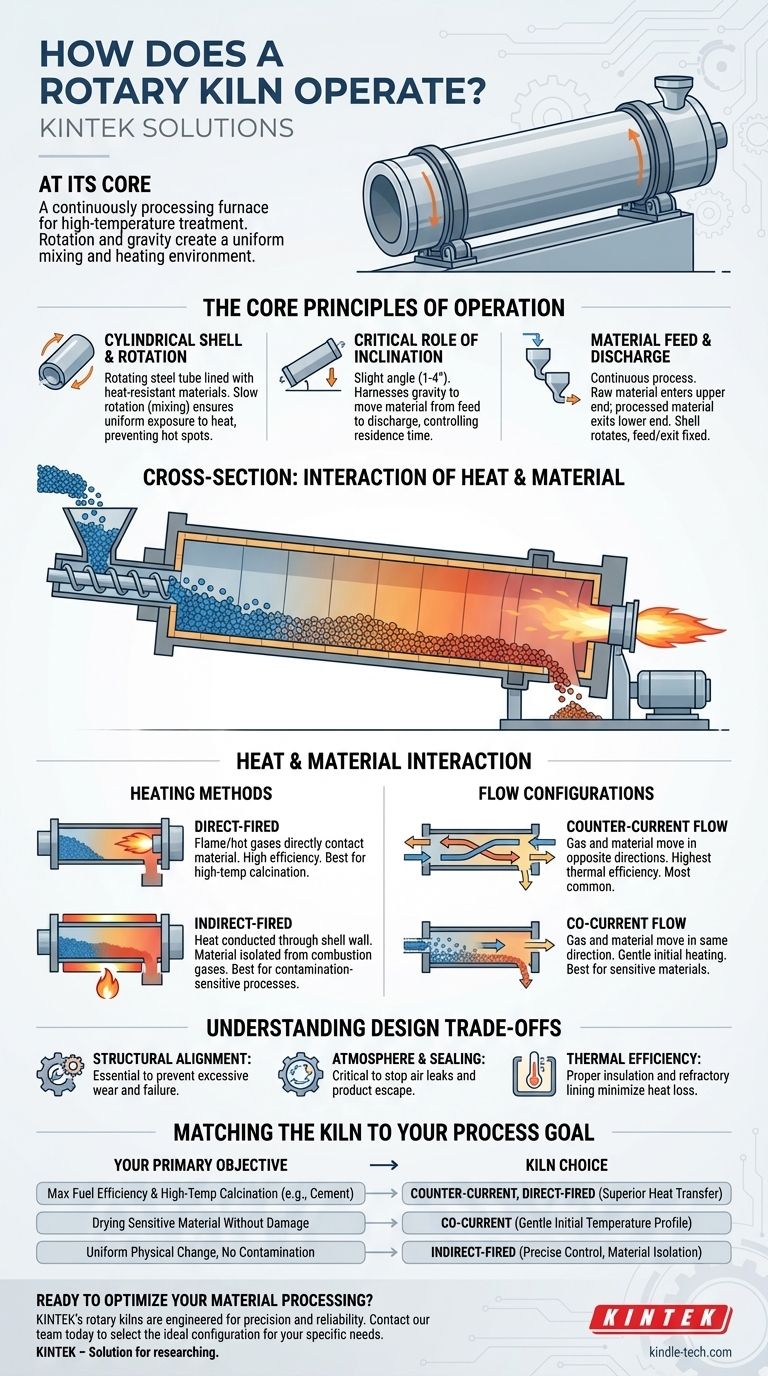

At its core, a rotary kiln is a continuously processing furnace designed for high-temperature treatment of solid materials. It consists of a long, cylindrical shell that is slightly inclined from the horizontal and rotates slowly on its axis. Raw material is fed into the higher end, and as the cylinder turns, the material gradually tumbles and moves down toward the lower end, where it is discharged.

The fundamental genius of the rotary kiln lies in its use of rotation and gravity. This combination creates a continuous, uniform mixing and heating environment that is exceptionally effective for inducing chemical reactions or physical changes in bulk solids.

The Core Principles of Operation

A rotary kiln's function is best understood by examining its key mechanical and thermal principles. Each component works in concert to achieve a specific process outcome.

The Cylindrical Shell and Rotation

The main body of the kiln is a large, rotating steel tube, often called a shell or retort. This shell is lined with heat-resistant materials.

The slow rotation is the primary mechanism for mixing. It constantly tumbles the material bed, ensuring that particles are evenly exposed to the heat source, which prevents hot spots and promotes uniform processing.

The Critical Role of Inclination

The kiln is mounted at a slight angle, typically between 1 and 4 degrees from the horizontal.

This inclination, combined with the tumbling action from rotation, harnesses gravity to move material from the feed end to the discharge end. The specific angle helps determine the residence time—how long the material spends inside the kiln.

The Material Feed and Discharge

Material processing is continuous. A feeding system, such as a screw feeder, introduces raw material into the stationary housing at the kiln's upper end.

At the lower end, the processed material exits through a discharge housing. This design allows the central cylinder to rotate freely while the feed and exit points remain fixed.

How Heat and Material Interact

The interaction between the hot gases and the solid material is the heart of the process. The direction of gas flow is a critical design choice that dictates the kiln's thermal efficiency and suitability for different materials.

Direct vs. Indirect Heating

Heat can be applied in two ways. Direct-fired kilns project a flame from a burner-pipe directly into the kiln, allowing hot gases to make direct contact with the material.

Indirect-fired kilns heat the exterior of the rotating shell, and that heat is conducted through the wall to the material inside. This is used when the material must not come into contact with combustion gases to avoid contamination.

Counter-Current Flow

In a counter-current configuration, hot gases flow in the opposite direction of the material. Gas is introduced at the discharge end and exits at the feed end.

This is the most common and thermally efficient method. The hottest gases encounter the most processed material, and the coolest gases encounter the fresh, wet feed, maximizing heat transfer across the entire length of the kiln.

Co-Current Flow

In a co-current configuration, hot gases and material flow in the same direction, entering at the upper end and exiting together at the lower end.

This setup is used for materials that are sensitive to thermal shock. It provides rapid initial heating but is generally less fuel-efficient than a counter-current system.

Understanding the Design Trade-offs

While highly effective, operating a rotary kiln involves balancing competing factors. The design must be precisely engineered to handle immense thermal and mechanical stress.

Structural Alignment and Stability

The sheer size and weight of a rotary kiln make its alignment essential. Improper alignment can cause excessive wear on the support rollers, tires, and drive system, leading to operational failure.

Atmosphere and Sealing

Effective seals between the rotating shell and the stationary feed and discharge housings are critical. These seals prevent air from leaking into the kiln (which can disrupt the combustion process) and stop dust or product from escaping into the environment.

Thermal Efficiency

A kiln's 360° heating surface is highly efficient at transferring heat. However, the vast surface area of the shell also presents a major source of heat loss to the surrounding environment. Proper insulation and refractory lining are crucial for minimizing energy waste.

Matching the Kiln to Your Process Goal

The configuration of a rotary kiln is adapted to achieve specific outcomes for different materials. Understanding your primary objective is key to selecting the right operational parameters.

- If your primary focus is maximum fuel efficiency and high-temperature calcination (e.g., cement): A counter-current, direct-fired system is the ideal choice for its superior heat transfer.

- If your primary focus is drying a temperature-sensitive material without damage: A co-current system provides a more gentle initial temperature profile, protecting the feedstock from thermal shock.

- If your primary focus is achieving a uniform physical change without contamination (e.g., coating granules): An indirect-fired kiln with precise control over the temperature profile and rotation speed is necessary.

By orchestrating rotation, inclination, and controlled heat flow, the rotary kiln remains one of the most versatile and powerful tools in modern material processing.

Summary Table:

| Feature | Direct-Fired Kiln | Indirect-Fired Kiln |

|---|---|---|

| Heat Transfer | Direct contact with flame & gases | Heat conducted through shell wall |

| Material Contact | Exposed to combustion gases | Isolated from combustion gases |

| Best For | High-temperature calcination (e.g., cement) | Contamination-sensitive processes |

| Feature | Counter-Current Flow | Co-Current Flow |

| :--- | :--- | :--- |

| Gas/Material Flow | Opposite directions | Same direction |

| Efficiency | High thermal efficiency | Lower thermal efficiency |

| Best For | Maximizing heat transfer | Gentle heating for sensitive materials |

Ready to optimize your material processing? Whether your goal is high-efficiency calcination, gentle drying, or contamination-free treatment, KINTEK's rotary kilns are engineered for precision and reliability. Our experts will help you select the ideal configuration—direct or indirect-fired, counter-current or co-current—to match your specific laboratory or industrial needs. Contact our team today to discuss your application and discover the KINTEK advantage in lab equipment and consumables.

Visual Guide

Related Products

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What is modified chemical vapour deposition method? The Inside-Out Process for Ultra-Pure Optical Fibers

- What is the future of pyrolysis oil? A Key to Circular Economy & Renewable Fuels

- What is the temperature range for calcination? Master the 800°C to 1300°C Process

- What are the advantages and disadvantages of rotary furnace? Maximize Uniformity & Efficiency in Thermal Processing

- What is the process of zirconium production? From Ore to High-Performance Metal & Ceramic