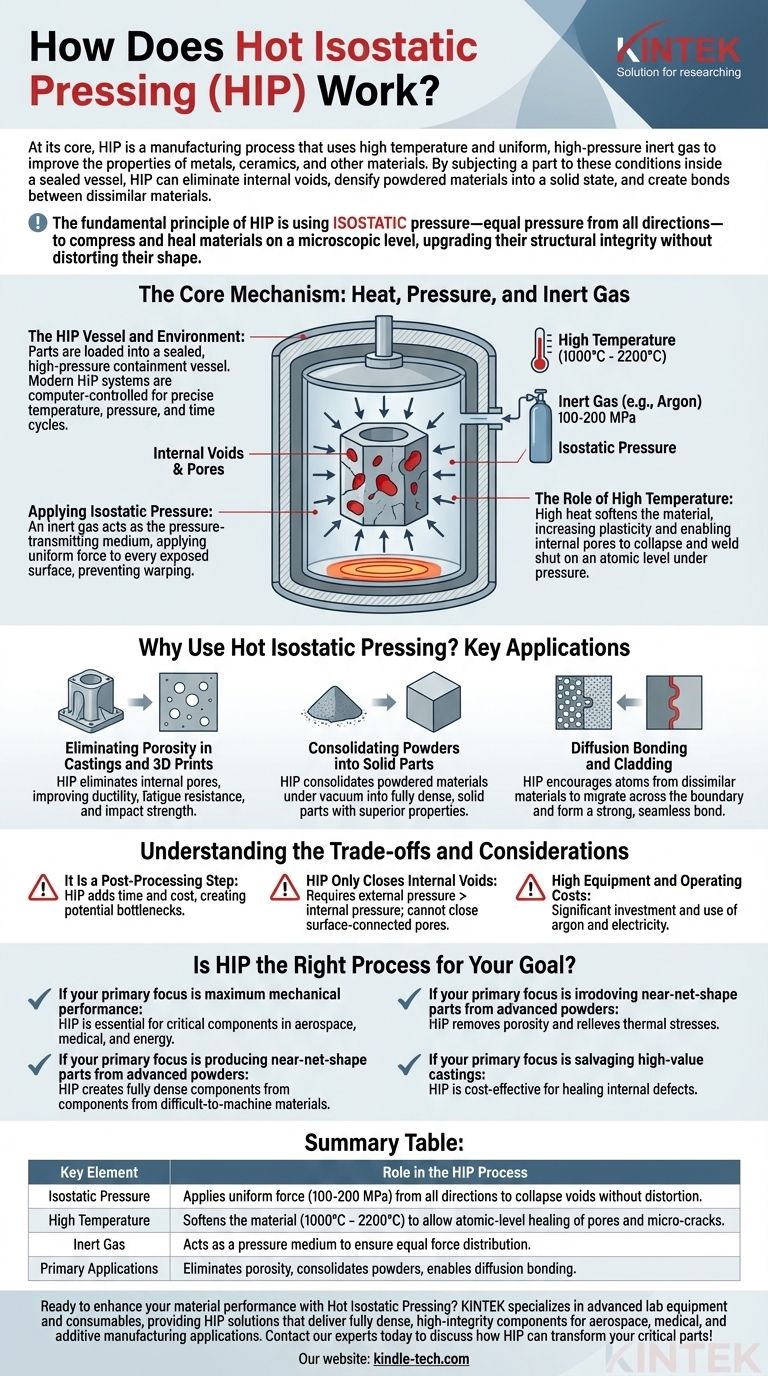

At its core, Hot Isostatic Pressing (HIP) is a manufacturing process that uses high temperature and uniform, high-pressure inert gas to improve the properties of metals, ceramics, and other materials. By subjecting a part to these conditions inside a sealed vessel, HIP can eliminate internal voids, densify powdered materials into a solid state, and create bonds between dissimilar materials that are otherwise impossible to join.

The fundamental principle of HIP is not simply applying heat and force, but using isostatic pressure—equal pressure from all directions—to compress and heal materials on a microscopic level, fundamentally upgrading their structural integrity without distorting their shape.

The Core Mechanism: Heat, Pressure, and Inert Gas

To understand how HIP achieves these results, we must look at the three key elements of the process and how they work in concert within the specialized equipment.

The HIP Vessel and Environment

The entire process takes place inside a high-pressure containment vessel, or chamber. Parts are loaded into this chamber, which is then sealed.

Modern HIP systems are computer-controlled, allowing operators to program precise cycles of temperature, pressure, and time tailored to the specific material and desired outcome.

Applying Isostatic Pressure

Once sealed, an inert gas—most commonly argon—is pumped into the vessel and pressurized. This gas acts as the pressure-transmitting medium.

The term isostatic means the pressure is applied uniformly to every exposed surface of the component. Imagine an object submerged deep in the ocean; the water pressure pushes on it equally from all sides. This is the same principle behind HIP, preventing the part from warping or changing its shape.

Pressures typically reach between 100 to 200 MPa (15,000 to 30,000 psi), which is immense force distributed perfectly across the part.

The Role of High Temperature

Simultaneously, a heating furnace inside the vessel raises the temperature, often between 1,000°C and 2,200°C.

This high heat doesn't melt the material but softens it, increasing its plasticity. In this state, the material is receptive to the high external pressure, which causes internal pores, voids, or micro-cracks to collapse and weld shut on an atomic level.

Why Use Hot Isostatic Pressing? Key Applications

The unique ability of HIP to heal internal defects makes it a critical process for improving part performance and enabling advanced manufacturing techniques.

Eliminating Porosity in Castings and 3D Prints

Both metal casting and additive manufacturing (3D printing) can leave behind microscopic internal pores. These voids are stress concentrators and can lead to premature part failure.

HIP eliminates this porosity, creating a fully dense, uniform microstructure. This dramatically improves mechanical properties like ductility, fatigue resistance, and impact strength.

Consolidating Powders into Solid Parts

HIP is a cornerstone of powder metallurgy. A powdered material, such as a metal alloy or ceramic, is sealed in a container under vacuum.

The container is then placed in the HIP vessel. The combination of heat and pressure consolidates the loose powder into a fully dense, solid part with superior properties, a process known as sintering.

Diffusion Bonding and Cladding

Because HIP applies pressure and heat below the material's melting point, it can be used to join dissimilar materials. This process, known as diffusion bonding, encourages atoms from each material to migrate across the boundary and form a strong, seamless bond.

Understanding the Trade-offs and Considerations

While powerful, HIP is not a universal solution. Understanding its limitations is key to using it effectively.

It Is a Post-Processing Step

HIP adds time and cost to the manufacturing workflow. It is a batch process, meaning parts must be loaded, processed, and unloaded, which can create bottlenecks compared to continuous processes.

HIP Only Closes Internal Voids

The process relies on external pressure being greater than any internal pressure. It is exceptionally effective at closing internal, hermetically sealed voids.

However, HIP cannot close pores or cracks that are connected to the surface, as the pressurized gas will simply fill the void, equalizing the pressure and preventing it from closing.

High Equipment and Operating Costs

HIP vessels are complex, precision-engineered machines designed to handle extreme conditions safely. The initial investment is significant, and the use of large amounts of argon and electricity results in high operating costs.

Is HIP the Right Process for Your Goal?

Deciding whether to use HIP requires aligning its capabilities with your specific technical and commercial objectives.

- If your primary focus is maximum mechanical performance: HIP is an essential step for critical components in aerospace, medical, and energy applications where failure is not an option.

- If your primary focus is improving the quality of 3D-printed metal parts: HIP is the industry standard for removing porosity and relieving thermal stresses, transforming a printed part into a high-performance, engineering-grade component.

- If your primary focus is producing near-net-shape parts from advanced powders: HIP is a foundational technology that enables the creation of fully dense components from materials that are difficult or impossible to machine or cast.

- If your primary focus is salvaging high-value castings: HIP is a cost-effective method for healing internal casting defects, saving complex parts that would otherwise be scrapped.

By understanding its principles, you can leverage Hot Isostatic Pressing not just as a repair tool, but as a method for engineering materials to their absolute peak potential.

Summary Table:

| Key Element | Role in the HIP Process |

|---|---|

| Isostatic Pressure | Applies uniform force from all directions using inert gas (e.g., argon) at 100-200 MPa to collapse internal voids without distortion. |

| High Temperature | Softens the material (1,000°C - 2,200°C) to allow atomic-level healing of pores and micro-cracks. |

| Inert Gas | Acts as a pressure medium to ensure equal force distribution across the part's surface. |

| Primary Applications | Eliminates porosity in castings/3D prints, consolidates powders, and enables diffusion bonding of dissimilar materials. |

Ready to enhance your material performance with Hot Isostatic Pressing? KINTEK specializes in advanced lab equipment and consumables, providing HIP solutions that deliver fully dense, high-integrity components for aerospace, medical, and additive manufacturing applications. Contact our experts today to discuss how HIP can transform your critical parts!

Visual Guide

Related Products

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Cylindrical Lab Electric Heating Press Mold for Laboratory Applications

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Cylindrical Press Mold with Scale for Lab

People Also Ask

- What are the components of a hot isostatic pressing system? A Guide to Core HIP Equipment

- What is the historical background of the Hot Isostatic Pressing (HIP) process? From Nuclear Roots to Industry Standard

- What is HIP treatment for metal? Eliminate Internal Defects for Superior Part Performance

- Is hot isostatic pressing a heat treatment? A Guide to Its Unique Thermomechanical Process

- How much energy does hot isostatic pressing consume? Unlock Net Energy Savings in Your Process