At its most fundamental level, a hot press machine works by applying precise heat and pressure to a material for a specific amount of time. This controlled combination of forces is used to trigger a physical or chemical change, such as melting solder to join electronics, activating an adhesive to laminate surfaces, or transferring a printed design onto a substrate like fabric or ceramic.

A hot press is not merely a heater and a clamp; it is a precision system designed to control a material's transformation. Its effectiveness comes from the ability to precisely manage heat, pressure, and time in a repeatable cycle, enabling everything from industrial fabrication to detailed design work.

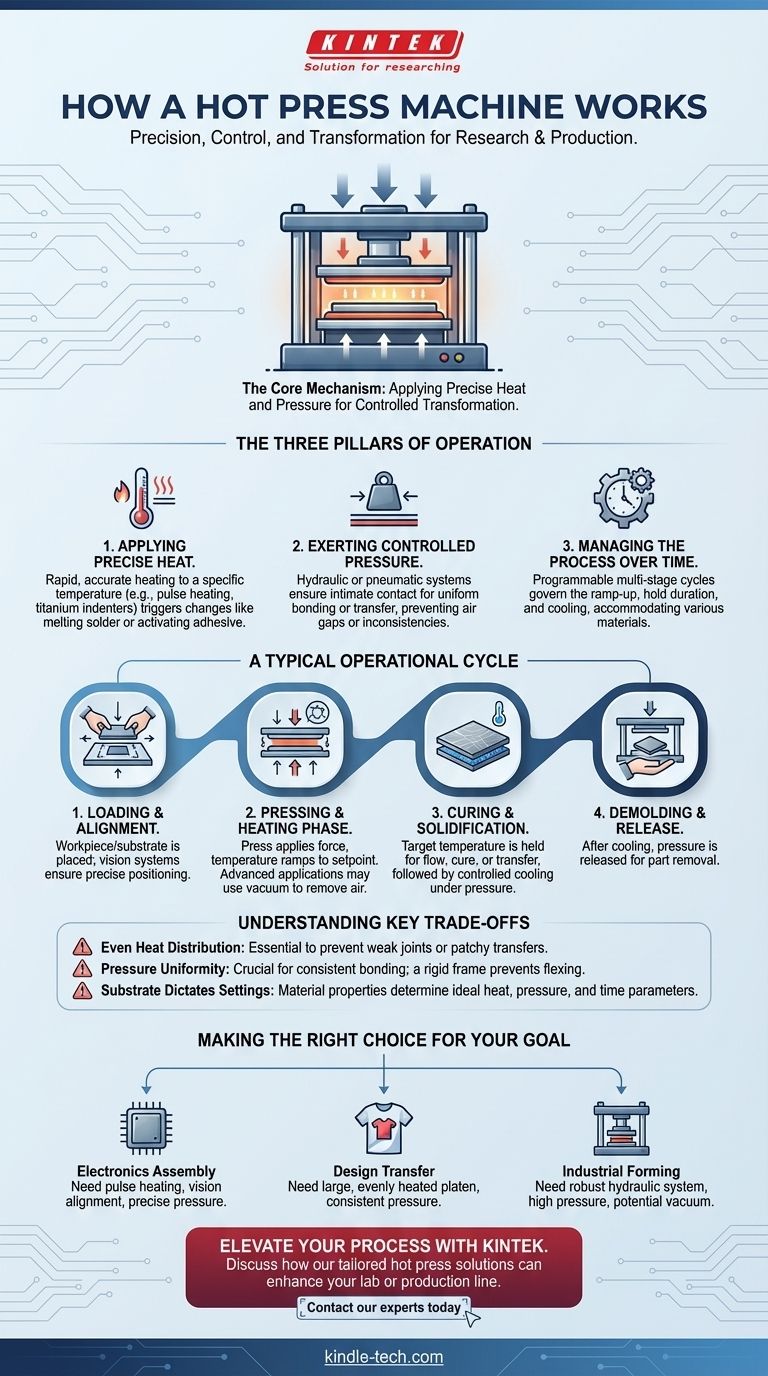

The Three Pillars of Operation: Heat, Pressure, and Time

A hot press functions by mastering three critical variables. The sophistication of the machine lies in how well it controls and integrates them.

Applying Precise Heat

The machine's primary function is to heat a workpiece to a specific temperature. This is often achieved using pulse heating technology or specialized heating elements.

High-end presses use indenters made of materials like titanium to ensure the temperature is distributed perfectly evenly across the entire contact surface. This prevents hot spots and ensures the entire bond or transfer is successful.

Exerting Controlled Pressure

Simultaneously, the machine applies force. This is typically driven by a hydraulic system using oil pressure, often supplemented by compressed air for specific actions.

The pressure ensures intimate contact between the parts being joined or between the transfer paper and the substrate. A well-designed press applies this pressure uniformly, which is crucial for a consistent outcome.

Managing the Process Over Time

The entire process is governed by an electronic control system. The user can program multi-stage cycles, dictating how quickly the temperature ramps up, how long it is held, and the precise duration of the pressure.

This programmability allows a single machine to be configured for vastly different materials and applications, from a quick fabric print to a complex electronic bonding cycle.

How a Typical Cycle Unfolds

While specific steps vary by application, the core process follows a predictable sequence automated by the machine's control system.

Step 1: Loading and Alignment

The workpiece, substrate, or components are placed into the machine. For high-precision tasks like electronics assembly, a CCD vision system may be used to ensure perfect alignment before the cycle begins.

Step 2: The Pressing and Heating Phase

The press closes, applying a pre-programmed amount of pressure. The heating element then activates, raising the temperature to the target setpoint.

In advanced applications like lamination, the machine may first create a vacuum to remove all air and moisture before applying positive pressure to form a perfect, bubble-free bond.

Step 3: Curing and Solidification

Once the target temperature is reached, it is held for a set duration to allow the solder to flow, the adhesive to cure, or the ink to transfer. The machine then begins a controlled cooling phase, often while still maintaining pressure to ensure the bond sets correctly.

Step 4: Demolding and Release

After the workpiece has cooled to a safe temperature, the machine releases all pressure and opens. The finished part can then be removed.

Understanding the Key Trade-offs

The quality of the final product is entirely dependent on the precision of the machine. Understanding these factors is critical for diagnosing issues and selecting the right equipment.

Even Heat Distribution is Non-Negotiable

An unevenly heated platen is the most common cause of failure. It results in weak solder joints on one side, or a faded, patchy design transfer on the other. This is why material choice and heating element design are paramount.

Pressure Uniformity Determines Consistency

If the press applies more force to the center than the edges, the bond or transfer will be inconsistent. A rigid, well-engineered frame (often a "four-column, three-plate" structure) is designed specifically to prevent this flexing and ensure uniform pressure.

The Substrate Dictates the Settings

There is no universal setting. The properties of the material being pressed—its thickness, heat tolerance, and composition—determine the ideal combination of heat, pressure, and time. Using settings for fabric on a ceramic tile will lead to failure, and vice versa.

Making the Right Choice for Your Goal

To select the right hot press, you must first define your primary application.

- If your primary focus is electronics assembly (soldering): You need a machine with pulse heating for rapid temperature changes, a vision system for alignment, and highly precise pressure control.

- If your primary focus is design transfer (fabric, mugs): You need a machine with a large, evenly heated platen and the ability to maintain consistent, uniform pressure across the entire surface.

- If your primary focus is industrial forming or lamination: You need a robust hydraulic press with high-pressure capabilities and potentially a vacuum system for flawless bonding.

Understanding these core principles empowers you to select the right machine and master its process for flawless results.

Summary Table:

| Key Variable | Role in the Process | Why It Matters |

|---|---|---|

| Heat | Raises material to a specific temperature. | Triggers physical/chemical changes like melting solder or activating adhesive. |

| Pressure | Applies force to ensure intimate contact. | Creates a consistent, uniform bond or transfer across the entire surface. |

| Time | Governs the duration of heating and cooling. | Allows for complete curing, solidification, and a repeatable process cycle. |

Ready to achieve precision and consistency in your lab or production line?

The principles of heat, pressure, and time are critical for success in applications like electronics soldering, material lamination, and design transfer. Choosing the right equipment is the first step to flawless results.

At KINTEK, we specialize in providing high-performance lab equipment, including hot press machines tailored to your specific needs—whether for delicate electronics assembly or robust industrial forming. Our expertise ensures you get a solution that delivers the precise control, uniform heating, and reliable performance your work demands.

Let's discuss how a KINTEK hot press can enhance your processes. Contact our experts today for a personalized consultation!

Visual Guide

Related Products

- Double Plate Heating Press Mold for Lab

- Automatic Laboratory Heat Press Machine

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- What does a hydraulic heat press do? Achieve Industrial-Scale, Consistent Pressure for High-Volume Production

- What role does a heated hydraulic press play in Cold Sintering (CSP)? Enhancing LATP-Halide Densification

- What role does a benchtop hot press play in densifying composite cathodes? Achieve <10% Porosity with Thermo-Mechanical Flow

- Why is precise pressure control via a hydraulic system necessary during hot pressing? Optimize Nanocopper Performance

- What is the purpose of a hot press? Transform Materials with Heat and Pressure

- How does a laboratory heating and stirring device assist in loading Pt particles? Precision Synthesis Explained

- What is the role of a laboratory hydraulic press in the preparation of inorganic perovskite energy materials?

- What technical conditions does a heated hydraulic press provide for PEO batteries? Optimize Solid-State Interfaces