At its core, a hydraulic press is a force multiplier. It operates on a simple yet profound principle of fluid dynamics to transform a modest input force into an immense output force. Using an incompressible liquid, typically oil, the machine leverages Pascal's Law to generate the pressure needed to compress, shape, or assemble materials with exceptional power.

A hydraulic press does not create energy; it transfers and multiplies force. The core insight is that pressure applied to a contained fluid is distributed equally in all directions, allowing a small force acting on a small area to generate a massive force on a larger area.

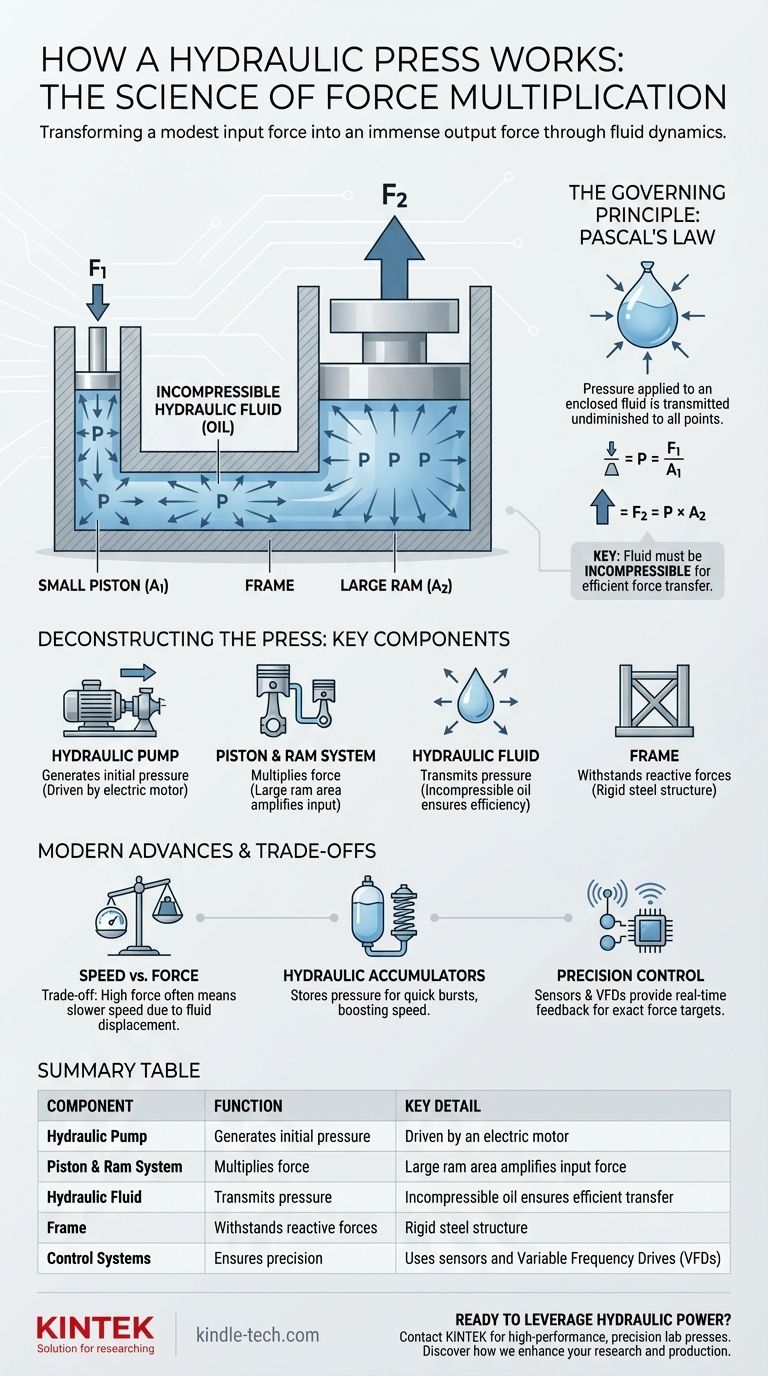

The Governing Principle: Understanding Pascal's Law

The entire operation of a hydraulic press is built upon a fundamental law of physics discovered by Blaise Pascal in the 17th century.

What is Pascal's Law?

Pascal's Law states that a change in pressure at any point in an enclosed, incompressible fluid is transmitted undiminished to all points throughout the fluid.

Imagine squeezing a water-filled balloon. The pressure you apply with your finger is felt equally on every part of the balloon's inner surface. A hydraulic system channels this effect in a controlled way.

The Force Multiplication Formula

The system uses two pistons of different sizes connected by a channel of hydraulic fluid. A small force (F1) is applied to a small piston with area (A1), creating pressure (P).

P = F1 / A1

This pressure is transmitted through the fluid and acts on a larger piston (the ram) with area (A2). Because the pressure is equal throughout the system, the resulting output force (F2) is immense.

F2 = P * A2

Since the area of the second piston (A2) is much larger than the first (A1), the output force (F2) is magnified by the same ratio.

The Role of an Incompressible Fluid

This principle only works because the hydraulic fluid (usually oil) is incompressible. Unlike a gas, a liquid does not noticeably shrink in volume under pressure.

This property ensures that the force applied to the first piston is efficiently transferred to the second, rather than being wasted on compressing the fluid itself.

Deconstructing the Hydraulic Press: Key Components

While the principle is simple, a functional press relies on several integrated components working together.

The Hydraulic Pump

The pump is the heart of the system. Driven by an electric motor, it circulates the hydraulic fluid and generates the initial pressure required to start the force multiplication process.

The Piston and Ram System

This is where the force multiplication occurs. The system consists of:

- The Input Piston: A smaller piston where the initial pressure is generated.

- The Ram: The large-diameter output piston that moves to press against the workpiece. Its large surface area is what multiplies the force.

The Hydraulic Fluid

This is the lifeblood of the machine. It is the medium that transmits pressure from the pump and input piston to the ram. It also serves to lubricate components and dissipate heat.

The Frame

The frame is the rigid steel structure that houses the components and must be strong enough to withstand the immense reactive forces generated by the press during operation.

Understanding the Trade-offs and Modern Advances

While powerful, hydraulic presses are not without their trade-offs. Modern technology, however, has addressed many of their traditional limitations.

Speed vs. Force

A fundamental trade-off in hydraulics is speed versus force. To move a large ram, a significant volume of fluid must be displaced, which can make hydraulic presses slower than their mechanical counterparts. They are masters of power, not necessarily speed.

The Role of Hydraulic Accumulators

To overcome speed limitations in certain applications, systems can include a hydraulic accumulator. This device is like a pressure battery. It stores high-pressure fluid from the pump during idle periods and can release it rapidly on demand, providing a quick burst of force and speed.

The Rise of Precision Control

Modern hydraulic presses are no longer simple brute-force machines. They integrate advanced technology for unmatched control:

- Sensors: Pressure sensors and displacement sensors (like grating rulers) provide real-time feedback on force and position with high accuracy.

- Variable Frequency Drives (VFDs): These control the speed of the pump's motor, allowing for precise and automatic adjustment of pressure and flow rate. This enables the machine to achieve and maintain exact force targets.

Making the Right Choice for Your Application

The brilliance of a hydraulic press lies in its adaptability. How you leverage its principles depends entirely on your objective.

- If your primary focus is generating maximum force: Your main concern is the ratio between the ram's surface area and the input piston's area. A larger ratio directly translates to greater force multiplication.

- If your primary focus is process control and precision: Your system's value is in its control logic, pressure sensors, and variable frequency drives. These components are essential for applications requiring repeatable and exact force.

- If your primary focus is operational speed: You must evaluate the pump's flow rate (volume per minute) and determine if a hydraulic accumulator is necessary to meet cycle time requirements.

By understanding the interplay of pressure, area, and fluid dynamics, you can fully leverage the immense and controllable power of any hydraulic system.

Summary Table:

| Component | Function | Key Detail |

|---|---|---|

| Hydraulic Pump | Generates initial pressure | Driven by an electric motor |

| Piston & Ram System | Multiplies force | Large ram area amplifies input force |

| Hydraulic Fluid | Transmits pressure | Incompressible oil ensures efficient transfer |

| Frame | Withstands reactive forces | Rigid steel structure |

| Control Systems | Ensures precision | Uses sensors and Variable Frequency Drives (VFDs) |

Ready to leverage the power of hydraulic presses in your lab? KINTEK specializes in high-performance lab equipment, including hydraulic presses designed for precision, durability, and maximum force control. Whether you need to compress, shape, or assemble materials with unmatched accuracy, our solutions are tailored to meet your specific laboratory requirements. Contact us today to discover how KINTEK can enhance your research and production processes with reliable, advanced hydraulic press technology.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- How is a laboratory hydraulic press utilized for LLZT green pellets? Optimize Densification for Solid Electrolytes

- What happens when you overheat hydraulic oil? Prevent Costly System Failure and Damage

- How is a hydraulic press so strong? Unlocking the Power of Force Multiplication

- What type of machine is a hydraulic press? A Powerful Force Multiplier for Crushing, Molding, and Forging

- Can a hydraulic press break a diamond? Yes, and here’s why hardness isn't strength.

- What is the significance of using a laboratory hydraulic press for ceramic green bodies? Achieve Maximum Green Density

- Why is a hydraulic press used for vacuum carbothermic magnesium reduction pellets? Protect Systems & Enhance Gas Flow

- What are the errors in XRF? Master Sample Preparation for Accurate Results