In forging, a hydraulic press uses a fluid-based system to apply immense, sustained, and highly controllable compressive force to a metal workpiece. Unlike hammers that deliver a sharp impact, a hydraulic press squeezes the metal slowly, allowing the material to flow and conform to the shape of a die. This methodical application of force makes it uniquely suited for creating large, complex, and high-strength components.

The core advantage of a hydraulic press in forging is not just its power, but its control. By applying constant pressure throughout its entire, lengthy stroke, it can shape difficult alloys and intricate geometries that are impossible to achieve with faster, impact-based forging methods.

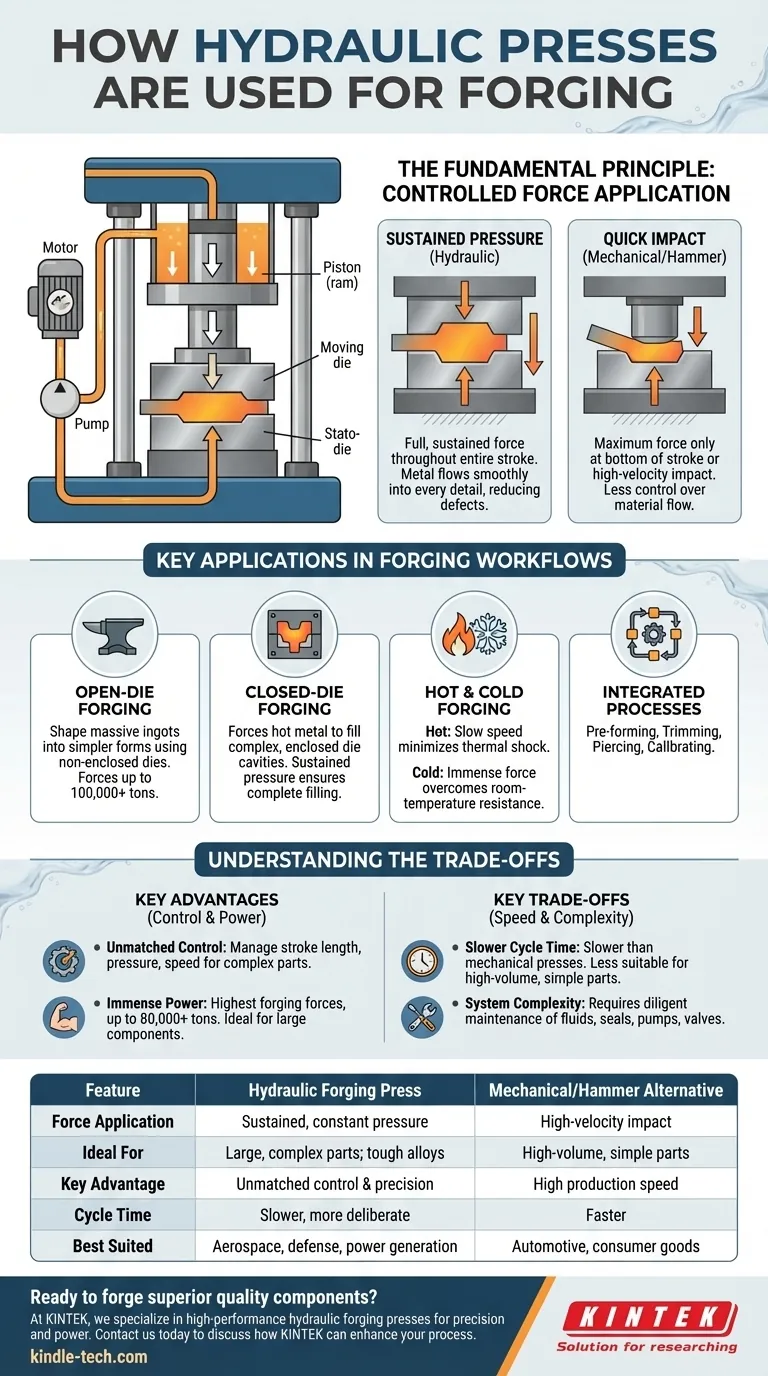

The Fundamental Principle: Controlled Force Application

How It Works

A hydraulic press operates on the principle of fluid dynamics. An electric motor drives a pump that pressurizes hydraulic fluid (typically oil) within a large cylinder. This pressure acts on a piston, or ram, which moves downwards with tremendous force.

The workpiece is placed between two dies—one attached to the moving ram and the other to a stationary bed. As the ram descends, it slowly squeezes the metal, forcing it to take the shape of the dies.

Sustained Pressure vs. Quick Impact

The defining characteristic of a hydraulic press is its ability to deliver full, sustained force throughout the entire stroke. This is fundamentally different from a mechanical press, which delivers maximum force only at the very bottom of its stroke, or a forging hammer, which delivers force through a high-velocity impact.

This slow, constant pressure is critical. It allows the metal to flow smoothly and completely into every detail of the die cavity, reducing the risk of internal defects and ensuring a consistent microstructure in the final part.

Versatility in Force and Speed

Modern hydraulic forging presses offer infinite control over the process. The speed of the ram can be adjusted to match the specific forming characteristics of the material being worked. This adaptability results in superior workpiece quality and significantly longer service life for the expensive forging dies.

Key Applications in Forging Workflows

Open-Die and Closed-Die Forging

Hydraulic presses are used for both major types of forging. In open-die forging, they shape massive metal ingots into simpler forms using non-enclosed dies, with some presses reaching forces of over 100,000 tons.

In closed-die (or impression-die) forging, the press forces hot metal to fill a complex, enclosed die cavity. The sustained pressure is ideal for ensuring that hard-to-form alloys completely fill intricate shapes.

Hot and Cold Forging

The controlled nature of a hydraulic press makes it suitable for both hot and cold forging. In hot forging, its slow speed minimizes thermal shock to the dies.

In cold forging, where metal is shaped at room temperature, the immense and sustained force is necessary to overcome the material's higher resistance to deformation.

Integrated Forging Processes

A hydraulic press isn't just used for the main forging step. It is often part of an entire production line.

- Pre-forming: Smaller presses are used to shape the initial workpiece to ensure proper mass distribution before the final forging.

- Trimming and Piercing: After forging, dedicated hydraulic presses trim away excess material (flash) and perform piercing operations.

- Calibrating: A final coining or calibrating step in a press ensures the part meets exact dimensional tolerances.

Understanding the Trade-offs

Key Advantage: Unmatched Control

The primary benefit is control. The ability to manage the stroke length, pressure, and speed allows for the production of highly complex parts with excellent metallurgical properties. Because there is no impact, the process is also less violent, causing less stress on the equipment and facility.

Key Advantage: Immense Power

Hydraulic presses are capable of generating the highest forging forces available, with some reaching capacities of over 80,000 tons. This makes them the only choice for producing exceptionally large components used in aerospace, defense, and power generation.

The Primary Trade-off: Speed

The main limitation of a hydraulic press is its relatively slow cycle time compared to a mechanical press. The time it takes to build up hydraulic pressure makes it less suitable for high-volume production of small, simple parts.

The Consideration: System Complexity

Hydraulic systems are more complex than their mechanical counterparts. They require diligent maintenance of fluids, seals, pumps, and valves to ensure reliable operation in tough manufacturing environments.

Making the Right Choice for Your Goal

If your primary focus is forging large, complex components or tough alloys: The sustained, controllable force of a hydraulic press is the ideal solution.

If your primary focus is achieving high-precision geometry and superior material properties: The adaptable speed and pressure of a hydraulic press give you unparalleled control over the material flow.

If your primary focus is high-speed, high-volume production of smaller parts: A mechanical press is almost always the more efficient and cost-effective choice.

Ultimately, choosing a hydraulic press for forging is a decision to prioritize control, power, and quality over raw production speed.

Summary Table:

| Feature | Hydraulic Forging Press | Mechanical/Hammer Alternative |

|---|---|---|

| Force Application | Sustained, constant pressure | High-velocity impact |

| Ideal For | Large, complex parts; tough alloys | High-volume, simple parts |

| Key Advantage | Unmatched control & precision | High production speed |

| Cycle Time | Slower, more deliberate | Faster |

| Best Suited | Aerospace, defense, power generation | Automotive, consumer goods |

Ready to forge superior quality components?

At KINTEK, we specialize in high-performance lab and industrial equipment, including hydraulic forging presses designed for precision and power. Whether you're working with tough alloys or need to create intricate geometries, our solutions provide the control and reliability your laboratory or production facility demands.

Contact us today to discuss how a KINTEK hydraulic press can enhance your forging process and deliver the consistent, high-strength results you need. Get in touch now!

Visual Guide

Related Products

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- What is KBr disc method? A Complete Guide to IR Spectroscopy Sample Prep

- Why is a laboratory hydraulic press used to compress powders into pellets? Enhance Solid-State Reaction Kinetics

- What core conditions does a laboratory hydraulic press provide for solid-state electrolyte pellets? Enhance Density!

- What is an example of a hydraulic press? Discover the Power of Laboratory Sample Preparation

- Why is a laboratory hydraulic press required during the preparation of Ti3AlC2 precursor pellets?