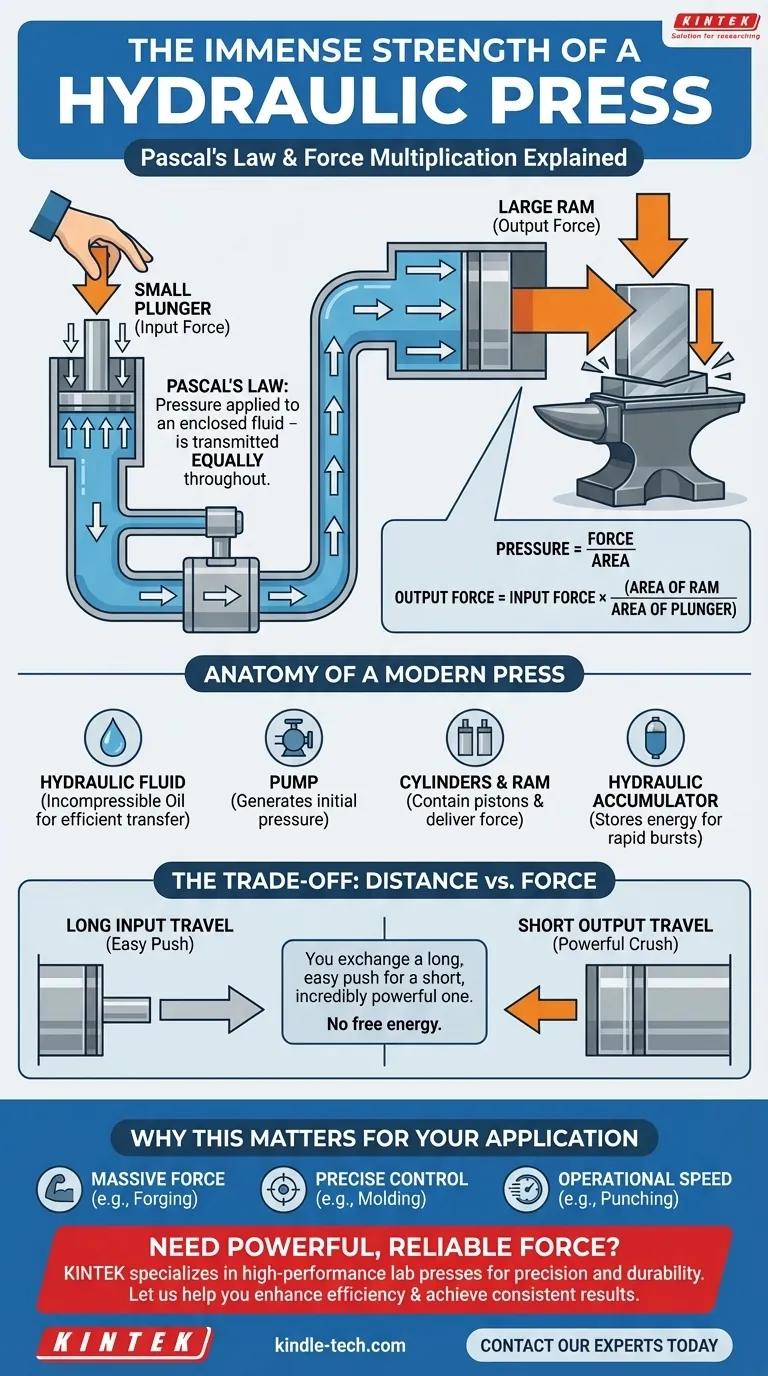

The immense strength of a hydraulic press comes from a principle called force multiplication, governed by Pascal's Law. By applying a small amount of force to an incompressible fluid (like oil) in a small, contained area, the resulting pressure is transferred equally to a much larger area. This transfer magnifies the initial force significantly, allowing the press to generate the crushing power needed for industrial tasks like forging metal and molding materials.

The core concept is a trade-off: a hydraulic press sacrifices travel distance to gain immense force. You push a small piston a long way with little effort to make a large piston move a short way with incredible strength.

The Core Principle: Pascal's Law Explained

To understand the power of a hydraulic press, you first need to understand the simple yet profound physics principle that enables it.

What is Pascal's Law?

Pascal's Law states that pressure applied to an enclosed, incompressible fluid is transmitted equally and undiminished throughout the entire fluid.

Imagine squeezing a sealed water bottle. The pressure you apply with your hand is felt everywhere inside the bottle, not just where your fingers are. This is the foundational concept.

The Two-Piston System

A hydraulic press is essentially a two-piston system connected by a chamber of hydraulic fluid.

- A small piston, often called the plunger, where the initial, smaller force is applied.

- A large piston, often called the ram, which delivers the final, magnified output force.

Because of Pascal's Law, the pressure created by pushing the small plunger is the exact same pressure exerted on the large ram.

The Magic of Force Multiplication

The key is the relationship between pressure, force, and area: Pressure = Force / Area.

Since the pressure is the same on both pistons, we can say that Force_input / Area_input = Force_output / Area_output.

This simple equation reveals the secret. If the output ram has an area 100 times larger than the input plunger, the output force will be 100 times greater than the input force. You achieve massive force multiplication simply by changing the surface area of the pistons.

Anatomy of a Modern Hydraulic Press

While the principle is simple, a modern press uses several components working in concert to deliver controlled power.

The Hydraulic Fluid

Most presses use a specialized oil as the fluid. This is because oil is virtually incompressible, meaning it won't squash under pressure, allowing for efficient force transfer. It also helps lubricate the moving parts of the press.

The Pump

An electric or manual pump is responsible for generating the initial pressure. It forces the hydraulic fluid into the system, applying the force onto the small plunger cylinder. The force of the press is determined by the pressure this pump can create.

The Cylinders and Ram

The system consists of the hydraulic cylinders that contain the pistons. High-pressure fluid is forced into the main cylinder, distributing pressure evenly onto the piston face. This pressure creates the powerful force that extends the ram to press, crush, or form an object.

The Hydraulic Accumulator

For applications requiring very strong and rapid thrust, some presses include a hydraulic accumulator. This is a device that stores high-pressure liquid while the press is idle. When needed, it can release this stored energy in a powerful burst, driving the ram with immense speed and force.

Understanding the Trade-offs

The force multiplication of a hydraulic press feels almost magical, but it isn't "free energy." It comes with a critical trade-off dictated by the laws of physics.

The Conservation of Work

You cannot get more work out of a system than you put into it. The trade-off for multiplying force is a reduction in distance.

The Distance Dilemma

To move the large ram just one inch, you must push the small plunger a much greater distance. If the ram has 100 times the area of the plunger, you will have to push the plunger 100 inches to move the ram just one inch.

You are exchanging a long, easy push for a short, incredibly powerful one.

System Integrity

The immense pressures involved demand robust construction. The entire system—cylinders, hoses, and seals—must be able to withstand extreme pressures without leaking or failing. This makes maintenance and build quality critical for safe and reliable operation.

Why This Matters for Your Application

Understanding this principle allows you to see why hydraulic systems are chosen for specific tasks.

- If your primary focus is massive force generation (e.g., metal forging): A hydraulic press is ideal because the output force can be scaled to enormous levels simply by increasing the pressure or the area of the output ram.

- If your primary focus is precise control (e.g., plastic molding): Hydraulic systems offer fine-tuned and consistent control over the applied force by precisely regulating the fluid's pressure.

- If your primary focus is operational speed and power (e.g., punching): A press equipped with a hydraulic accumulator provides the rapid, high-energy strokes necessary for high-throughput industrial processes.

By mastering the simple physics of pressure and area, the hydraulic press transforms a small input into a force capable of shaping the modern world.

Summary Table:

| Key Component | Role in Generating Strength |

|---|---|

| Pascal's Law | Pressure applied to fluid is transmitted equally throughout the system. |

| Two-Piston System | A small input piston applies force, which is multiplied by a larger output piston (ram). |

| Force Multiplication | Output force = Input force × (Area of Ram / Area of Plunger). |

| Hydraulic Fluid | Incompressible oil efficiently transfers pressure without loss. |

| Trade-off | Massive force gain comes with a proportional reduction in movement distance. |

Need reliable, powerful force for your lab or production line?

KINTEK specializes in high-performance lab equipment, including hydraulic presses designed for precision and durability. Whether you're molding materials, preparing samples, or forging, our presses deliver the controlled power you need.

Let us help you enhance your operational efficiency and achieve consistent results. Contact our experts today to find the perfect hydraulic solution for your specific application!

Visual Guide

Related Products

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- What is a sintering process? A Guide to Fusing Powders into High-Performance Parts

- What is a heated hydraulic press used for? Essential Tool for Curing, Molding, and Laminating

- What technical conditions does a heated hydraulic press provide for PEO batteries? Optimize Solid-State Interfaces

- Why do you need to follow the safety procedure in using hydraulic tools? Prevent Catastrophic Failure and Injury

- What are heated hydraulic presses used for? Molding Composites, Vulcanizing Rubber, and More