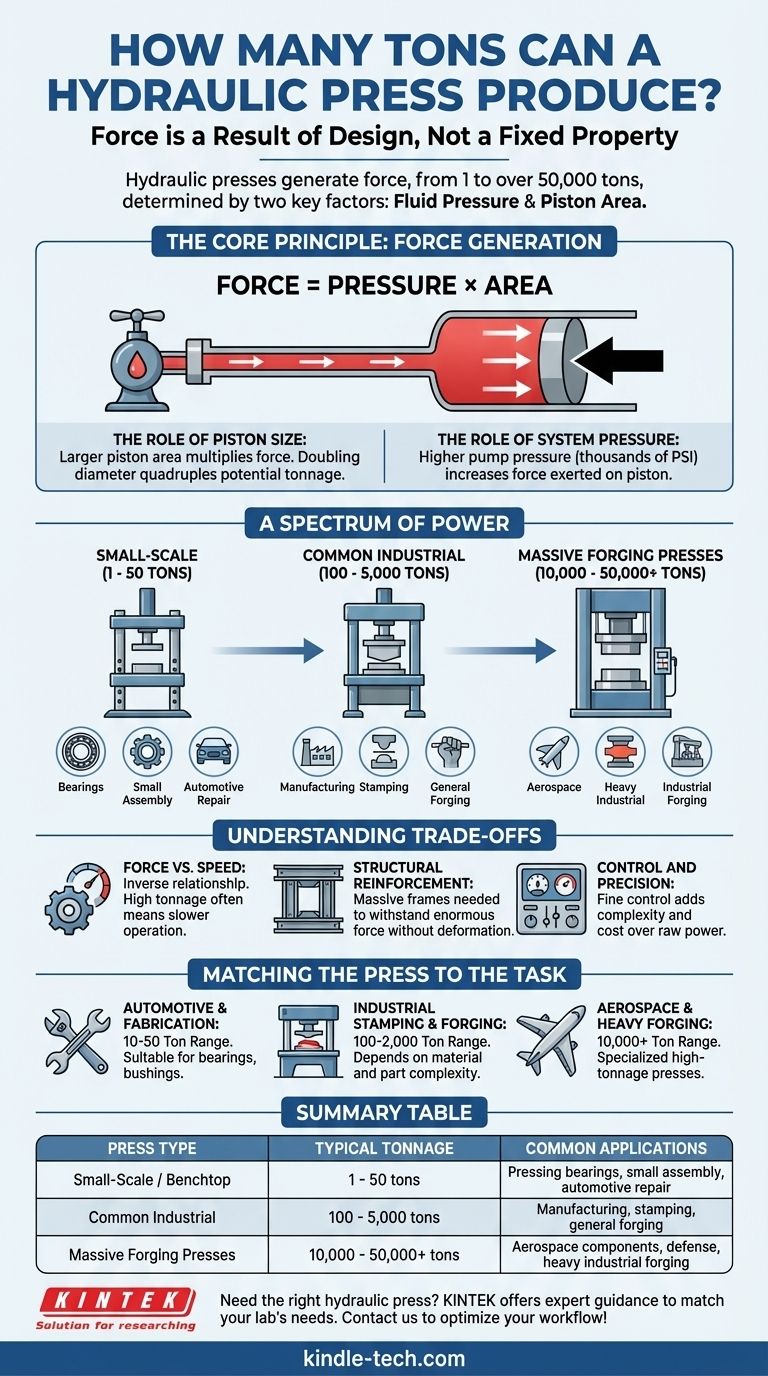

The force a hydraulic press can produce varies enormously, from small benchtop models producing a single ton to colossal industrial machines capable of generating over 50,000 tons of force. There is no single answer because the tonnage is not a fixed property but a direct result of the machine's specific design and engineering.

The core principle to understand is that a hydraulic press doesn't have a set amount of power; it generates it. Its maximum force is determined by just two factors: the pressure of its hydraulic fluid and the surface area of its main piston.

The Core Principle: How Force is Generated

The operation of every hydraulic press is governed by a fundamental law of physics. Understanding this principle is key to understanding its immense power potential.

Pascal's Law in Action

A hydraulic system works based on Pascal's Law, which states that pressure applied to an enclosed fluid is transmitted undiminished to every portion of the fluid and the walls of the container.

The formula is simple: Force = Pressure × Area. A hydraulic pump creates the pressure, and the piston provides the area.

The Role of Piston Size (Area)

This is where force multiplication happens. The system applies a specific fluid pressure (e.g., 3,000 pounds per square inch or PSI) across the entire surface of the main piston or ram.

A larger piston provides more surface area for that pressure to act upon, resulting in a proportionally greater output force. Doubling the piston's diameter quadruples its surface area, thus quadrupling the potential tonnage.

The Role of System Pressure

The other variable is the hydraulic system's maximum operating pressure. High-performance pumps can generate immense fluid pressure, often thousands of PSI.

The higher the pressure the pump can sustain, the more force is exerted on every square inch of the piston, directly increasing the press's maximum tonnage.

A Spectrum of Power: From Benchtop to Industrial Giants

Because the force is a product of design, hydraulic presses exist across a vast spectrum of power, tailored to specific tasks.

Small-Scale Presses

These are often found in machine shops and garages for tasks like pressing bearings or small assembly work. Their capacity is typically in the 1 to 50-ton range.

Common Industrial Presses

Used for manufacturing, stamping, and general forging, these presses form the backbone of many industries. They commonly operate in the 100 to 5,000-ton range.

Massive Forging Presses

At the extreme end are presses used for aerospace, defense, and heavy industrial applications, such as forging aircraft wing spars or turbine components. These giants can exert forces of 10,000 to over 50,000 tons.

Understanding the Trade-offs

Simply building for higher tonnage introduces critical engineering compromises that must be considered.

Force vs. Speed

There is almost always an inverse relationship between maximum force and operational speed. A pump can only move a specific volume of fluid per minute.

To move a very large piston (for high tonnage) at a reasonable speed requires an enormous and expensive hydraulic power unit. Often, high-tonnage presses move quite slowly.

Structural Reinforcement

The force generated by the piston is equally exerted back onto the frame of the press. A 10,000-ton press must have a frame capable of withstanding 10,000 tons of force without deforming.

This requires massive, heavily engineered structures, which dramatically increase the machine's cost, size, and weight. The weight of a press (e.g., 20 kg) is a result of this structural need, not a cause of its force.

Control and Precision

While some applications require raw power, others, as noted in forging complex shapes, demand fine control over that power.

Integrating systems for precise control over speed and pressure adds complexity and cost, representing a trade-off against a simpler, purely power-focused design.

Matching the Press to the Task

The right question is not "how much force can a press produce," but "how much force is required for my specific application?"

- If your primary focus is automotive repair or small fabrication: A workshop press in the 10 to 50-ton range provides more than enough force for tasks like removing bearings and bushings.

- If your primary focus is industrial stamping or medium-duty forging: A production press between 100 and 2,000 tons is likely required, depending on the material thickness and part complexity.

- If your primary focus is large-scale aerospace or industrial forging: This demands a specialized, high-tonnage press engineered specifically for the component, often exceeding 10,000 tons.

Ultimately, the power of a hydraulic press is a direct and predictable result of its design, governed by the clear principles of fluid dynamics.

Summary Table:

| Press Type | Typical Tonnage Range | Common Applications |

|---|---|---|

| Small-Scale / Benchtop | 1 - 50 tons | Pressing bearings, small assembly, automotive repair |

| Common Industrial | 100 - 5,000 tons | Manufacturing, stamping, general forging |

| Massive Forging Presses | 10,000 - 50,000+ tons | Aerospace components, defense, heavy industrial forging |

Need the right hydraulic press for your specific application? KINTEK specializes in lab equipment and consumables, offering expert guidance to match your laboratory's unique needs with the perfect hydraulic press solution. Whether you require precise control for complex shapes or high tonnage for demanding materials, our team can help you optimize your workflow. Contact us today to discuss your requirements and discover how KINTEK can enhance your lab's capabilities!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic Laboratory Heat Press Machine

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- How does temperature affect forging? Master Hot, Cold, and Warm Forging for Optimal Results

- What is a hydraulic forging press used for? Harnessing Controlled Power for Complex Metal Forming

- How is a laboratory hydraulic press utilized in rubberwood sample preparation for FTIR? Master Precise KBr Pelleting

- What products are made by press forging? High-Strength Components for Aerospace, Automotive & Energy

- What is the role of a laboratory hydraulic press in the performance testing of glycerol-based fuel additives?

- What is a hydraulic press in simple words? Harness Immense Force for Shaping and Crushing

- What is the function of a laboratory hydraulic press in the preparation of LAGP solid electrolyte substrates?

- What is the purpose of the XRF test? Rapid, Non-Destructive Elemental Analysis