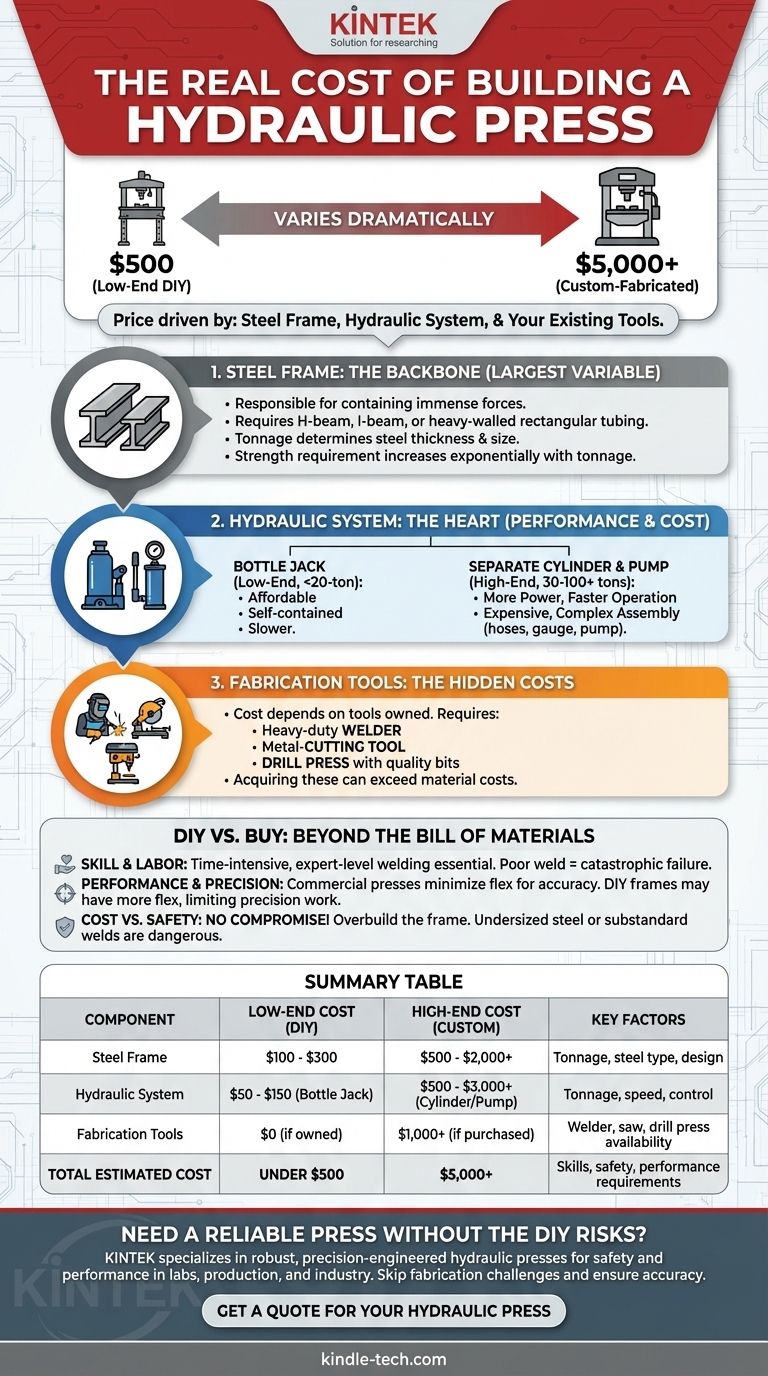

The cost to build a hydraulic press varies dramatically based on its size, tonnage, and complexity, ranging from under $500 for a simple, low-tonnage shop press to well over $5,000 for a more powerful, custom-fabricated machine. The final price is driven by three main factors: the cost of the steel frame, the type of hydraulic system you choose, and whether you already own the necessary metalworking tools.

While it's tempting to focus only on the cost of parts, the true calculation is more complex. The decision to build a press is a trade-off between material cost, your personal time, your fabrication skill, and the non-negotiable requirement for safety and performance.

Breaking Down the Core Component Costs

A hydraulic press appears simple, but its cost is spread across several critical components. Understanding each one helps clarify the total investment required.

The Steel Frame: The Backbone of the Press

The frame is responsible for containing the immense forces generated by the hydraulic system. Its material and construction will be the single largest variable in your budget.

Most DIY press frames are built from structural steel shapes like H-beam, I-beam, or heavy-walled rectangular tubing. The required thickness and size of this steel are directly proportional to the tonnage you want to achieve.

Doubling the tonnage does not just double the steel requirement; the need for strength increases exponentially. This is where a significant portion of your budget will go.

The Hydraulic System: The Heart of the Machine

The hydraulic system creates the force. Here, you have a fundamental choice that dramatically impacts cost and performance.

- Bottle Jack: This is the most common and affordable option for DIY presses, typically in the 6- to 20-ton range. A high-quality bottle jack is a self-contained, reliable, and inexpensive power source.

- Separate Cylinder and Pump: For higher tonnage (30-100 tons or more) or faster operation, you'll need a dedicated hydraulic cylinder, a pump (hand, air-over-hydraulic, or electric), hoses, and a pressure gauge. This system offers more control and power but is significantly more expensive and complex to assemble.

Fabrication and Tooling: The Hidden Costs

You cannot assemble a press with a simple wrench set. The cost of fabrication depends entirely on the tools you already own.

Building a sturdy press frame requires, at minimum:

- A heavy-duty welder capable of creating structurally sound welds.

- A metal-cutting tool like a chop saw, band saw, or plasma cutter.

- A drill press with high-quality bits for boring clean holes through thick steel.

If you don't own this equipment, the cost of acquiring it can easily exceed the cost of the press materials themselves.

The DIY vs. Buy Decision: Beyond the Bill of Materials

A purely financial comparison is misleading. The decision to build involves factors far more valuable than the cost of steel and a hydraulic jack.

Skill and Labor: Your Time Is a Cost

Fabricating a press frame is a time-consuming and skill-intensive process. It involves precise measuring, cutting, drilling, and—most importantly—expert-level welding.

A poor weld is not an aesthetic flaw; it's a catastrophic failure point waiting to happen. The energy stored in a press under load is enormous, and a weld failure can be incredibly dangerous. You must be honest about your welding capabilities.

Performance and Precision: The Limits of a DIY Build

Commercial presses are engineered to minimize frame flex under load. A rigid frame is essential for any work requiring precision, such as broaching or seating bearings perfectly straight.

A DIY frame, even if strong, will likely have more flex than a professionally engineered and manufactured counterpart. For rough work like bending thick metal or pressing out bushings, this may not matter. For precision work, it's a critical limitation.

Understanding the Trade-offs

Building a press involves a series of critical trade-offs. Being aware of them is key to a successful and safe project.

Cost vs. Safety: The Most Critical Trade-off

There is no room for compromise here. Attempting to save money by using undersized steel or by creating substandard welds is courting disaster. Always overbuild your frame for the tonnage you intend to use. When in doubt, add more reinforcement.

Simplicity vs. Power: The Hydraulic Choice

A bottle jack is simple and cheap but is generally slower and limited to lower tonnages. A component-based hydraulic system is more powerful and can be automated with an electric pump, but it adds significant cost and complexity.

Rigidity vs. Material Cost: Why Frame Design Matters

A well-designed frame can be stronger and more rigid than a poorly designed one that uses more steel. Research established designs, such as H-frames and A-frames, to understand how forces are distributed. Spending time on design can save you money on materials and result in a better-performing press.

Making the Right Choice for Your Goal

To decide whether to build or buy, evaluate your primary objective.

- If your primary focus is light-duty shop tasks and you have strong welding skills: A DIY build using a bottle jack and a well-designed H-frame can be a highly cost-effective and rewarding solution.

- If your primary focus is production work, high precision, or high tonnage (50+ tons): Purchasing a commercially manufactured and certified press is the correct choice for ensuring safety, reliability, and performance.

- If your primary focus is the project itself as a learning experience: Building a press can be an excellent metalworking project, provided you prioritize safe design principles and are honest about your fabrication capabilities.

Ultimately, the best decision comes from a clear-eyed assessment of your true needs, your existing skills, and the inherent risks of containing immense force.

Summary Table:

| Component | Low-End Cost (DIY) | High-End Cost (Custom) | Key Factors |

|---|---|---|---|

| Steel Frame | $100 - $300 | $500 - $2,000+ | Tonnage, steel type, design complexity |

| Hydraulic System | $50 - $150 (Bottle Jack) | $500 - $3,000+ (Cylinder/Pump) | Tonnage, speed, control needs |

| Fabrication Tools | $0 (if owned) | $1,000+ (if purchased) | Welder, saw, drill press availability |

| Total Estimated Cost | Under $500 | $5,000+ | Skills, safety, and performance requirements |

Need a reliable hydraulic press without the DIY risks? KINTEK specializes in robust, precision-engineered lab equipment and hydraulic presses designed for safety and performance. Whether you're in a research lab, production facility, or industrial setting, our solutions ensure accuracy and durability. Contact us today to find the perfect press for your needs and skip the fabrication challenges!

Get a Quote for Your Hydraulic Press

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic Laboratory Heat Press Machine

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- What is an example of a hydraulic press? Discover the Power of Laboratory Sample Preparation

- How much force can a hydraulic press exert? Understanding its immense power and design limits.

- Why is the KBr plate used in FTIR? Achieve Clear, Accurate Solid Sample Analysis

- What is the use of potassium bromide in IR? Achieve Clear Solid Sample Analysis with KBr Pellets

- What is KBr disc method? A Complete Guide to IR Spectroscopy Sample Prep