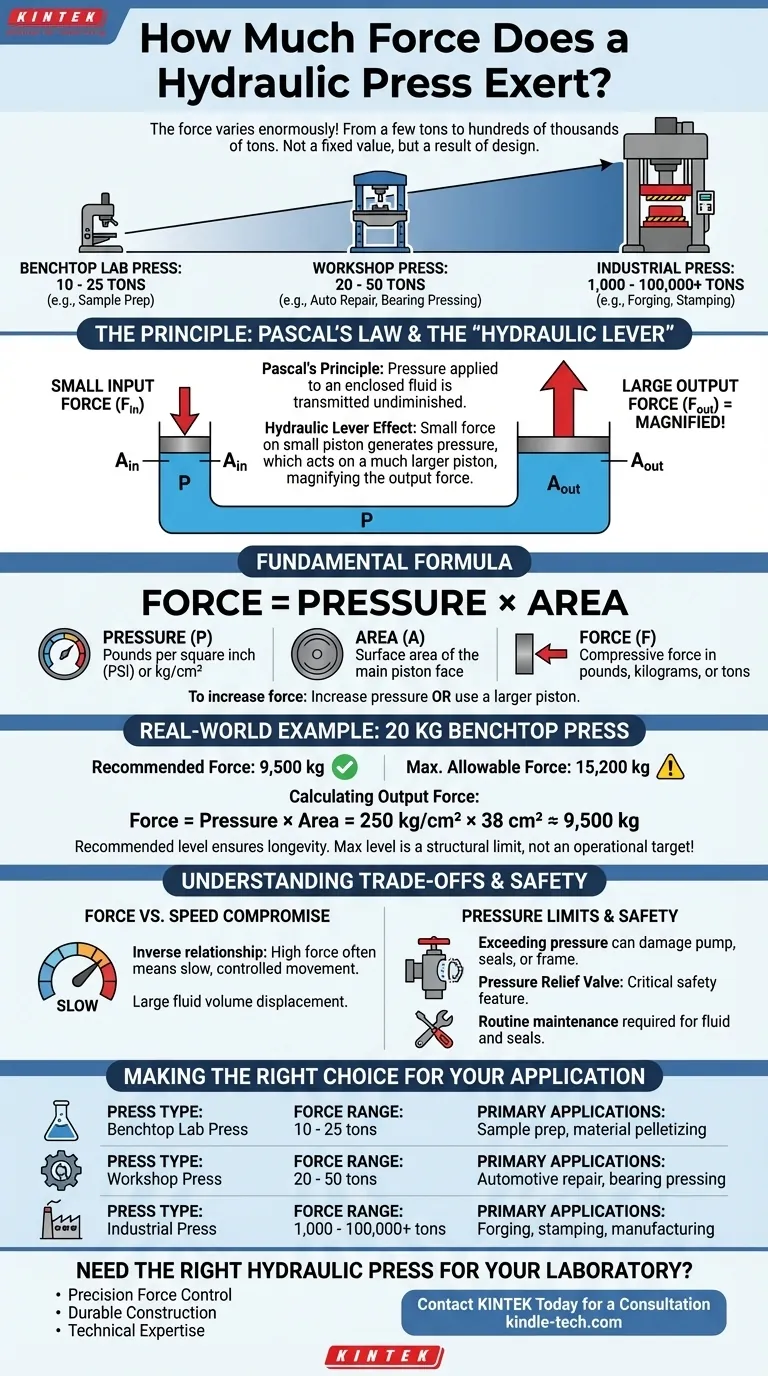

The force a hydraulic press exerts varies enormously, from a few tons for a small workshop press to hundreds of thousands of tons for massive industrial machines. For a specific 20 kg benchtop model, the maximum recommended force is 9,500 kg (approximately 9.5 metric tons or 10.5 US tons), with a maximum allowable force of 15,200 kg (15.2 metric tons). However, these numbers are just one example; the force is not a fixed value but a result of the system's design.

A hydraulic press does not have one specific force rating. Its output force is a direct product of the hydraulic fluid pressure and the surface area of the piston applying the force, a principle that allows it to generate immense force from a relatively small input.

The Principle Behind the Power: Pascal's Law

The incredible force multiplication of a hydraulic press is governed by a fundamental rule of fluid dynamics discovered centuries ago. Understanding this principle is key to understanding the machine's capability.

At its Core: Pascal's Principle

A hydraulic press operates on Pascal's Principle. This states that pressure applied to an enclosed, incompressible fluid is transmitted undiminished to every portion of the fluid and the walls of the containing vessel.

In simple terms, if you apply 250 kg of force per square centimeter (kg/cm²) of pressure to the hydraulic oil, that exact pressure is present everywhere within the system.

The "Hydraulic Lever" Effect

Think of the system as a "hydraulic lever." A small force applied to a small piston generates pressure in the fluid. This pressure then acts on a much larger piston, and because the surface area of this second piston is much greater, the resulting output force is magnified significantly.

This is how a hand-pumped hydraulic jack can lift a car, and it's why these presses are known for generating massive forces, not small ones.

The Fundamental Formula: Force = Pressure x Area

The output force of any hydraulic press can be calculated with a simple formula: Force = Pressure × Area.

- Force: The amount of compressive force the press exerts, measured in pounds, kilograms, or tons.

- Pressure: The pressure of the hydraulic fluid, measured in pounds per square inch (PSI) or kg/cm².

- Area: The surface area of the main piston face that is pushing on the workpiece.

This relationship shows that you can increase the output force by either increasing the system's pressure or by using a press with a larger piston.

Deconstructing a Real-World Example

Let's look at the specifications for a small, 20 kg benchtop press to see how these numbers work in practice. The specifications list a "maximum recommended power" of 9,500 kg at 250 kg/cm².

Clarifying Force vs. Pressure

The specifications use the term "power," but technically they are referring to force (measured in kilograms-force) and pressure (measured in kg/cm²). The 9,500 kg is the output force, and the 250 kg/cm² is the pressure of the fluid creating that force.

Using our formula, we can deduce the piston area: Area = Force / Pressure = 9,500 kg / 250 kg/cm² = 38 cm². This corresponds to a piston with a diameter of about 7 cm (or 2.75 inches).

Recommended vs. Maximum Allowable Force

The specifications list two figures: a recommended force (9,500 kg) and a maximum allowable force (15,200 kg).

Operating at the recommended level ensures the longevity and safety of the machine's seals, frame, and components. Pushing to the absolute maximum risks catastrophic failure and should be avoided. This higher rating is a structural limit, not an operational target.

Understanding the Trade-offs

While capable of immense force, hydraulic presses are not without their operational limitations. The design choices that maximize force often impact other performance characteristics.

The Force vs. Speed Compromise

There is an inverse relationship between force and speed. To move a large, high-force piston, a significant volume of hydraulic fluid must be displaced. This often results in a slow, controlled movement.

The example press has a maximum piston stroke of just 25 mm (about 1 inch), highlighting that these machines are designed for powerful compression over short distances, not rapid, repetitive motion.

Pressure Limits and System Safety

The heart of the system is a pump designed to generate a specific maximum pressure. Exceeding this pressure can damage the pump, blow out hydraulic seals, or even fracture the press frame. For this reason, all hydraulic systems are equipped with a pressure relief valve as a critical safety feature.

Maintenance and Complexity

A hydraulic press is a system of pumps, valves, seals, and fluid. This system requires routine maintenance. Hydraulic fluid must be kept clean and at the proper level, and seals can wear out over time, leading to leaks and a loss of pressure.

Making the Right Choice for Your Application

The "right" amount of force is entirely dependent on your goal. Understanding the different classes of presses helps put the numbers in context.

- If your primary focus is lab work or sample preparation: A benchtop press in the 10 to 25-ton range, similar to the one in our example, is typically sufficient for pelletizing materials for analysis.

- If your primary focus is automotive repair or a machine shop: A freestanding workshop press in the 20 to 50-ton range is a common choice for pressing bearings, gears, or straightening parts.

- If your primary focus is industrial manufacturing: The requirements are highly specialized. Forging and stamping presses can easily exceed 1,000 tons, with the largest machines reaching into the tens of thousands of tons.

By understanding the relationship between pressure, area, and force, you can effectively evaluate any hydraulic press and select the right tool for the job.

Summary Table:

| Press Type | Typical Force Range | Primary Applications |

|---|---|---|

| Benchtop Lab Press | 10 - 25 tons | Sample preparation, material pelletizing |

| Workshop Press | 20 - 50 tons | Automotive repair, bearing pressing |

| Industrial Press | 1,000 - 100,000+ tons | Forging, stamping, manufacturing |

Need the Right Hydraulic Press for Your Laboratory?

KINTEK specializes in laboratory equipment and consumables, offering hydraulic presses perfectly suited for your research and sample preparation needs. Whether you require a precise 10-ton benchtop model for material testing or a more robust system for your lab's unique applications, our experts will help you select the ideal press based on your specific force, pressure, and workflow requirements.

We provide:

- Precision Force Control: Achieve consistent, accurate results for material testing and pellet preparation.

- Durable Construction: Built to withstand rigorous laboratory use with safety features like pressure relief valves.

- Technical Expertise: Get personalized guidance to match the perfect press to your application.

Ready to enhance your lab's capabilities? Contact KINTEK today for a consultation on our range of hydraulic presses and discover how we can support your laboratory's success.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Heated Hydraulic Press Machine with Heated Plates Split Manual Laboratory Hot Press

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Laboratory Manual Hydraulic Pellet Press for Lab Use

People Also Ask

- What is the advantage of KBr? Unmatched IR Transparency for Precise Spectroscopy

- Why use KBr for IR? Achieve Clear, Unobstructed Spectra for Solid Samples

- What is the pressed powder pellet method? A Guide to Accurate FTIR Sample Preparation

- Why are KBr pellets used in FTIR? Achieve Clear, Accurate Solid Sample Analysis

- What is the pellet technique in IR? Master Solid Sample Preparation for Clear Spectroscopy