The force of a hydraulic press varies enormously, ranging from a single ton for small workshop units to over 50,000 tons for massive industrial forging machines. The specific force is not a single value but is determined by the press's design and intended application. Its power comes from a principle that allows a small input force to be multiplied into an immense output force.

A hydraulic press does not create energy; it multiplies force. By applying pressure to a confined fluid (like oil), the system leverages Pascal's Law to transfer that pressure to a much larger piston, generating a compressive force far greater than the initial effort applied.

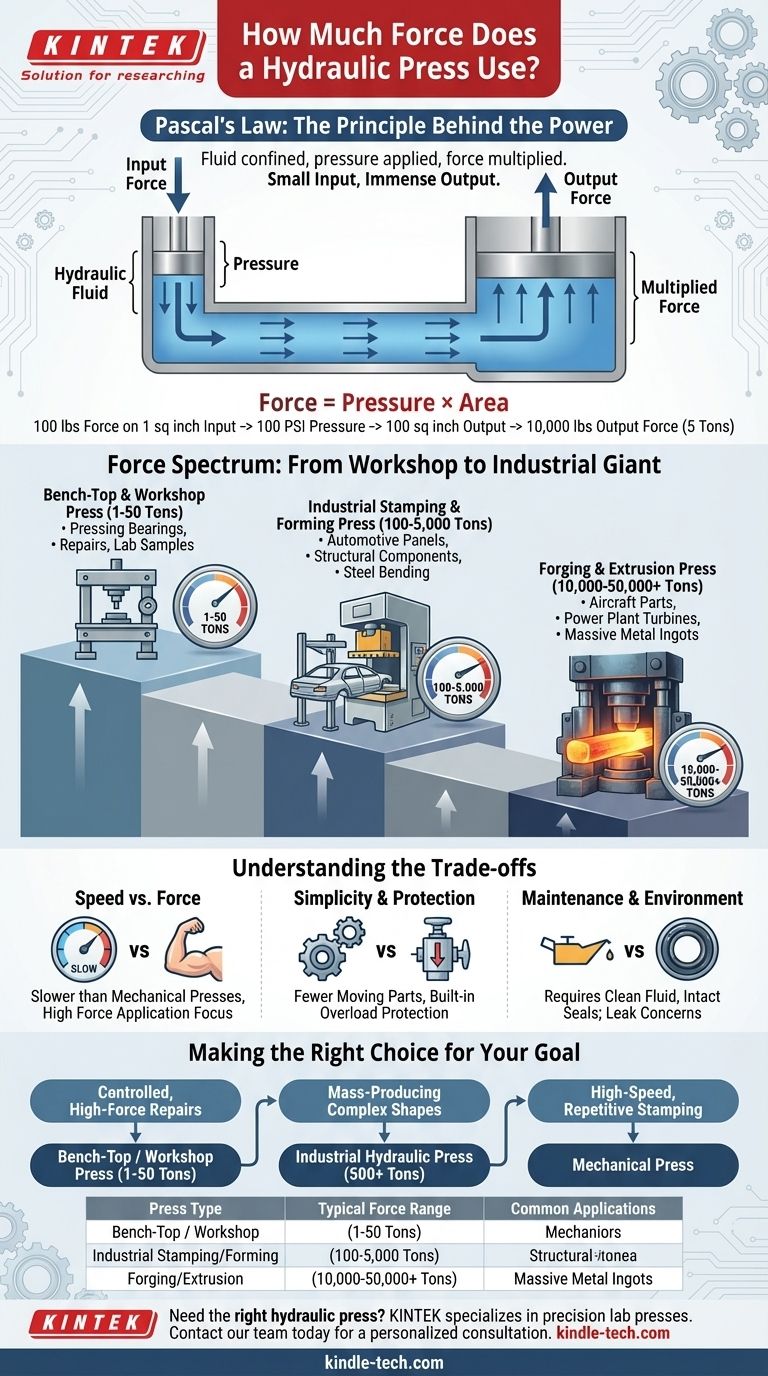

The Principle Behind the Power: Pascal's Law

The incredible force of a hydraulic press is not magic but a direct application of a fundamental fluid dynamics principle discovered by Blaise Pascal.

The Concept of a "Hydraulic Lever"

Think of a hydraulic press as a hydraulic lever. In a mechanical lever, you apply force over a long distance to move a heavy object a short distance. A hydraulic press does something similar using fluid.

A small piston (the input) applies pressure to a hydraulic fluid. Because the fluid is confined in a sealed system, this pressure is transmitted equally in all directions.

This pressure then acts on a much larger piston (the output). Since the surface area of the output piston is many times greater than the input piston, the force exerted is multiplied by the same factor.

How Force is Multiplied

The formula is simple: Force = Pressure × Area.

If you apply 100 pounds of force to a 1-square-inch input piston, you create 100 pounds per square inch (PSI) of pressure in the fluid. If that 100 PSI then pushes against a 100-square-inch output piston, the resulting output force is 10,000 pounds (5 tons).

The Role of the Hydraulic Cylinder

The hydraulic cylinder is the component that does the work. It houses the output piston and rod. As pressurized fluid enters the cylinder, it pushes the piston, extending the rod with immense force to press, stamp, or form a material.

How Much Force? A Look at the Spectrum

The term "hydraulic press" covers a vast range of equipment, each designed with a specific tonnage.

Bench-Top and Workshop Presses

At the lower end are presses used in machine shops, garages, and labs. These typically range from 1 to 50 tons. They are used for tasks like pressing bearings, repairing small parts, or preparing lab samples.

Industrial Stamping and Forming Presses

This is where the numbers become staggering. Presses used for automotive manufacturing, aerospace, and heavy industry can range from 100 to 5,000 tons. These machines stamp out car body panels, form structural components, and bend thick steel plates.

Forging and Extrusion Presses

At the absolute peak are forging presses that shape massive metal ingots. These colossal machines can exert 10,000 to over 50,000 tons of force, capable of shaping titanium and steel alloys for critical applications like aircraft landing gear or power plant turbines.

Understanding the Trade-offs

While immensely powerful, hydraulic presses are not the universal solution for every task. Their design comes with specific trade-offs.

Speed vs. Force

The primary trade-off is speed. Moving a large volume of fluid to generate high force takes time. Therefore, hydraulic presses are generally slower than mechanical presses, which are often preferred for high-speed, repetitive stamping of smaller parts.

Simplicity and Overload Protection

A major advantage is design simplicity. With fewer moving parts than a complex mechanical press, they can be more reliable and less expensive to manufacture for high-tonnage applications. They also have built-in overload protection; the system simply cannot exceed the pressure set by its relief valve, protecting the machine and tools.

Maintenance and Environment

Hydraulic systems require clean fluid and intact seals to function. Leaks can be a source of maintenance issues and environmental concerns. The quality and temperature of the hydraulic fluid must be carefully managed for consistent performance.

Making the Right Choice for Your Goal

Understanding the principle of force multiplication helps you select the right tool for the job.

- If your primary focus is controlled, high-force repairs or lab work: A bench-top or workshop press (1-50 tons) provides the necessary power and precision without the industrial scale.

- If your primary focus is mass-producing complex metal shapes: An industrial hydraulic press (500+ tons) is required for its ability to deliver sustained, immense force for deep-drawing and forming operations.

- If your primary focus is high-speed, repetitive stamping: A mechanical press may be more suitable, as its faster cycle rate is often more critical than the sheer force of a hydraulic system.

Ultimately, the power of a hydraulic press is a direct result of multiplying force by leveraging fluid pressure across different surface areas.

Summary Table:

| Press Type | Typical Force Range | Common Applications |

|---|---|---|

| Bench-Top / Workshop | 1 - 50 tons | Pressing bearings, small repairs, lab sample prep |

| Industrial Stamping/Forming | 100 - 5,000 tons | Automotive panels, structural components, steel bending |

| Forging/Extrusion | 10,000 - 50,000+ tons | Aircraft parts, power plant turbines, massive metal ingots |

Need the right hydraulic press for your specific force requirements? KINTEK specializes in lab equipment and consumables, offering precision hydraulic presses tailored to your laboratory's unique needs. Whether you require a compact bench-top model for sample preparation or a robust system for material testing, our experts can help you select the perfect equipment to enhance your workflow efficiency and accuracy. Contact our team today for a personalized consultation and discover how KINTEK's reliable lab solutions can power your research and development.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- Are hydraulic presses powered by water? Discover the critical role of hydraulic oil.

- What is the pellet technique in IR? Master Solid Sample Preparation for Clear Spectroscopy

- Why use KBr for IR? Achieve Clear, Unobstructed Spectra for Solid Samples

- What role does a laboratory hydraulic press play in the preparation of solid electrolyte pellets? Ensure Data Accuracy

- What is the use of KBr? Master Sample Prep for Accurate IR Spectroscopy