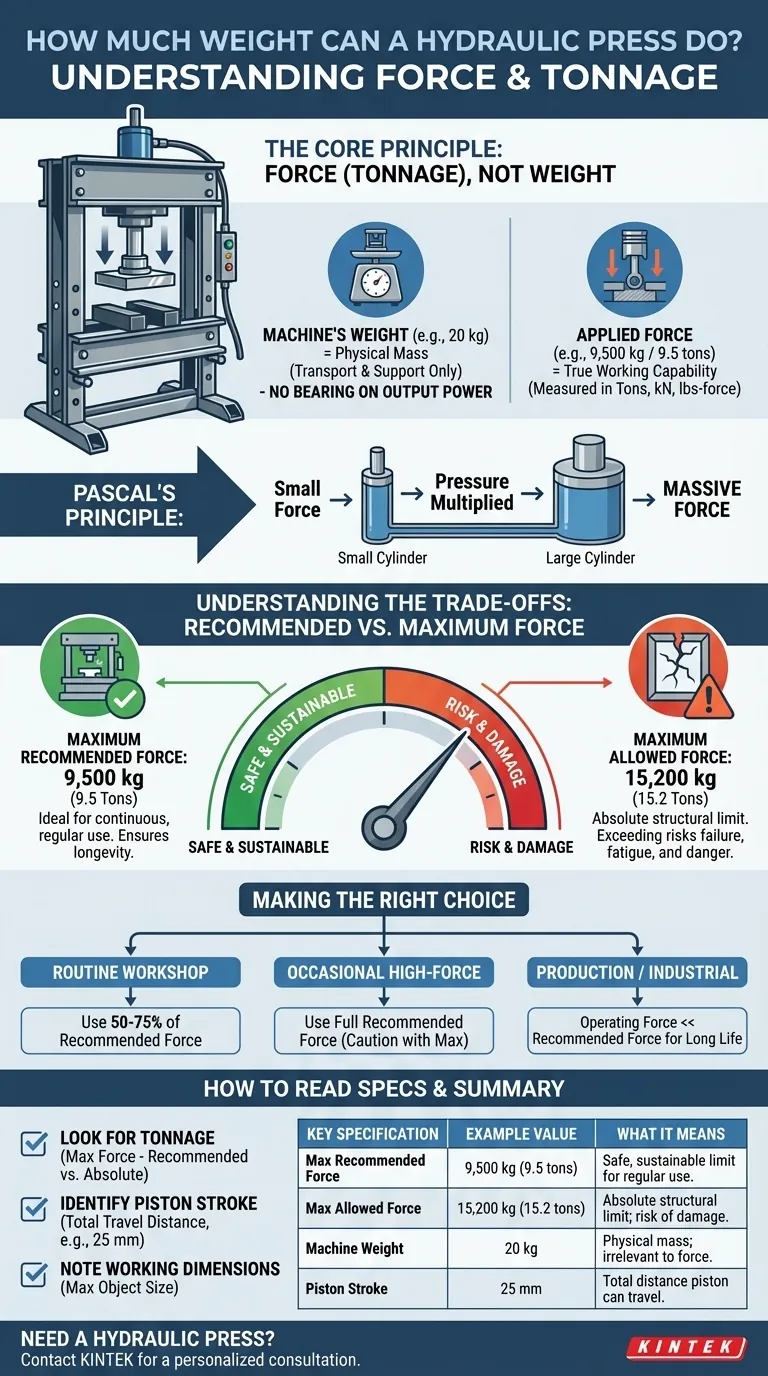

The force a hydraulic press can exert varies dramatically, from a few tons for small benchtop models to thousands of tons for industrial machines. Based on the specifications provided for a common manual benchtop press, it can apply a recommended force of 9,500 kg (9.5 metric tons) and a maximum allowed force of 15,200 kg (15.2 metric tons). The machine's own weight, in this case 20 kg, is entirely unrelated to the force it can generate.

The crucial takeaway is that a press's capability is not measured by its own weight, but by the force (tonnage) it can apply. You must always distinguish between the recommended force for continuous use and the absolute maximum force, which risks damaging the machine.

The Core Principle: Force, Not Weight

Many users confuse the weight of the machine with the force it can generate. Understanding the difference is the first step to using a press safely and effectively.

Distinguishing the Press's Weight

A hydraulic press might weigh 20 kg, 50 kg, or over a ton. This figure, its physical mass, has no bearing on its output power.

This weight is only relevant for transportation, installation, and ensuring your workbench can support the machine itself.

Understanding Force (Tonnage)

The "power" of a hydraulic press is correctly measured as force. This is typically listed in metric tons (1,000 kg), kilonewtons (kN), or pounds-force.

For example, a specification of 250 kN is equivalent to a force of approximately 25,500 kg (or 25.5 metric tons). This is the number that tells you the press's true working capability.

The Role of Pressure

This massive force is generated through Pascal's Principle. A small force is applied to a fluid (hydraulic oil) in a small cylinder, and this pressure is transmitted to a much larger cylinder, multiplying the force.

Specifications like 250 kg/cm² or 400 kg/cm² refer to the internal pressure within the hydraulic system needed to achieve a certain force output.

Understanding the Trade-offs: Recommended vs. Maximum Force

A press's specification sheet often lists two different force ratings. Knowing the difference is critical for both safety and the longevity of your equipment.

What is "Maximum Recommended Force"?

This is the safe, sustainable limit for regular, repeated use. In the example provided, this is 9,500 kg.

Operating at or below this level ensures the press functions accurately without putting excessive strain on its frame, seals, or hydraulic components. This is the rating you should use for your day-to-day calculations.

What is "Maximum Allowed Force"?

This is the absolute structural limit of the press. The example press has a maximum allowed force of 15,200 kg.

Pushing the machine to this level should be a rare event. It is the point beyond which you risk permanent damage to the press frame, failure of the hydraulic seals, or a dangerous release of stored energy.

The Dangers of Exceeding Limits

Consistently operating a press near its maximum allowed limit will lead to metal fatigue in the frame and premature wear on the piston seals.

In a worst-case scenario, overloading the press can cause a catastrophic failure, potentially cracking the frame or ejecting the workpiece at high speed.

How to Read Any Hydraulic Press Specification

When evaluating a hydraulic press for your needs, focus on three key metrics on its technical data sheet.

Look for "Tonnage" or "Maximum Force"

This is the single most important number. It will be listed in tons, kg, or kN. Be sure to identify if the number is the recommended or absolute maximum force.

Identify the Piston Stroke

The "maximum piston stroke" (e.g., 25 mm) tells you the total distance the pressing piston can travel. This is crucial for ensuring the press can accommodate the height of your workpiece and the distance you need to press it.

Note the Working Dimensions

Specifications like the height and width of the working area tell you the maximum size of an object that can fit inside the press frame.

Making the Right Choice for Your Task

Use this framework to select and operate a press based on your specific application.

- If your primary focus is routine workshop tasks: Choose a press where your typical jobs require no more than 50-75% of its maximum recommended force.

- If your primary focus is occasional high-force jobs: You can utilize the full maximum recommended force and, with caution, approach the maximum allowed force for very infrequent tasks.

- If your primary focus is production or industrial use: Select a press where your standard operating force is significantly lower than the maximum recommended force to guarantee a long service life.

By understanding these key specifications, you move from asking "how much?" to knowing exactly what force a press can deliver for your specific goal.

Summary Table:

| Key Specification | Example Value | What It Means |

|---|---|---|

| Maximum Recommended Force | 9,500 kg (9.5 tons) | Safe, sustainable limit for regular use. |

| Maximum Allowed Force | 15,200 kg (15.2 tons) | Absolute structural limit; risk of damage if exceeded. |

| Machine Weight | 20 kg | Physical mass; irrelevant to force output. |

| Piston Stroke | 25 mm | Total distance the pressing piston can travel. |

Need a Hydraulic Press That Matches Your Force Requirements?

Choosing the right press is critical for safety, efficiency, and the longevity of your equipment. KINTEK specializes in lab equipment and consumables, offering a range of hydraulic presses designed for various force needs—from benchtop models for routine tasks to industrial-grade machines for high-force applications.

Our experts can help you select a press where your typical jobs align perfectly with the machine's recommended force, ensuring optimal performance and durability for your laboratory.

Contact us today for a personalized consultation and find the perfect hydraulic press for your lab's needs!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic Laboratory Heat Press Machine

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- What is KBr pellet used in the examination of? Mastering FTIR Spectroscopy for Solid Samples

- What is a hydraulic cooler? The Essential Guide to Protecting Your Hydraulic System

- What is the difference between C type and H type power press machines? Choose the Right Frame for Your Precision Needs

- What safety items must be used when using a hydraulic press? Essential PPE and Procedures to Prevent Accidents

- What is the function of a laboratory hydraulic press in Diamond/Ti composite preparation? Ensuring Atomic Bonding

- What is the difference between hydro pneumatic press and hydraulic press? Choose the Right Press for Your Application

- Why was the hydraulic press invented? To Solve the Industrial Revolution's Force Problem

- What precautions should be taken during IR spectroscopy? Master Sample Prep for Accurate Results