Yes, absolutely. A hydraulic forging press is strictly limited to a maximum force. This limit is not arbitrary; it is a fundamental characteristic determined by the press's engineering design, including the maximum pressure of its hydraulic system and the physical size of its components.

The maximum force of a hydraulic press is a calculated ceiling, defined by two primary factors: the highest pressure the hydraulic system can safely generate and the surface area of the piston it acts upon. Exceeding this limit would lead to catastrophic failure of the system.

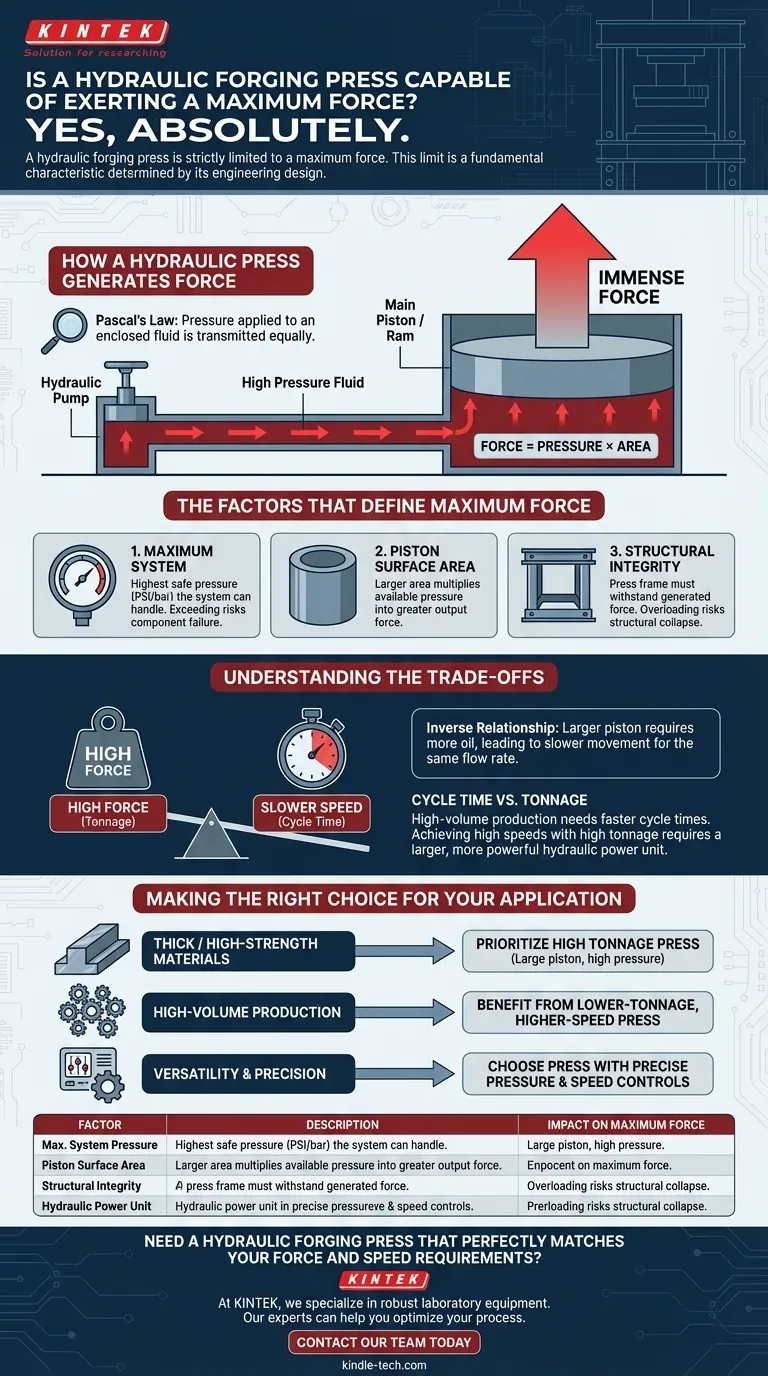

How a Hydraulic Press Generates Force

The Core Principle: Pascal's Law

At the heart of every hydraulic press is a fundamental principle of fluid dynamics known as Pascal's Law. This law states that pressure applied to an enclosed, incompressible fluid is transmitted equally throughout the fluid.

In simple terms, a hydraulic pump creates high pressure in the system's oil. This pressurized oil is then directed into a large cylinder.

Translating Pressure into Force

The immense force of the press is generated when this high-pressure fluid pushes against a large piston, often called the ram. The relationship is governed by a simple, powerful formula: Force = Pressure × Area.

A modest amount of hydraulic pressure, when applied over the large surface area of the main piston, is multiplied into a massive amount of output force. This is how a press can be rated for thousands of tons of force.

The Factors That Define Maximum Force

Factor 1: Maximum System Pressure

The hydraulic system, which includes the pump, hoses, and seals, has a maximum operating pressure. This is a critical safety and design limit.

Pumps are designed to generate a specific maximum pressure (measured in PSI or bar). Attempting to push the system beyond this rated pressure risks rupturing hoses, blowing seals, and causing catastrophic pump failure.

Factor 2: Piston Surface Area

The second critical factor is the surface area of the main piston inside the hydraulic cylinder. As the formula shows, a larger piston area multiplies the available pressure into a greater output force.

Therefore, the maximum theoretical force is the highest safe pressure the system can sustain multiplied by the surface area of that main piston.

Factor 3: Structural Integrity

The press itself—its frame, columns, and bed—must be strong enough to withstand the immense force it generates. The structure is engineered to resist the equal and opposite reaction of the force being applied.

If a press were somehow forced to operate beyond its rated tonnage, the steel frame itself would be the next point of failure, leading to structural collapse.

Understanding the Trade-offs

The Relationship Between Force and Speed

A common misconception is that a press can deliver maximum force and maximum speed simultaneously. The two are inversely related for a given hydraulic power unit.

A press with a very large piston generates more force, but it also requires a larger volume of oil to move a certain distance. This means it will naturally move slower than a press with a smaller piston, assuming the same hydraulic fluid flow rate.

Cycle Time vs. Tonnage

For high-volume production, cycle time is critical. A faster press completes more cycles per hour. However, achieving high speeds with high tonnage requires a much larger, more powerful, and more expensive hydraulic power unit capable of delivering a higher flow rate of oil.

This creates a fundamental design and purchasing trade-off: you must balance the need for raw power (tonnage) with the need for production speed (cycle time).

Making the Right Choice for Your Application

Choosing or operating a press requires understanding your primary goal. The "best" press is the one that aligns with your specific operational needs.

- If your primary focus is forming thick or high-strength materials: You must prioritize a press with a high tonnage rating, which means it is built with a large piston and a high-pressure hydraulic system.

- If your primary focus is high-volume production of smaller parts: You may benefit from a lower-tonnage, higher-speed press to maximize parts per hour and reduce cycle times.

- If your primary focus is versatility: Look for a press with modern controls that allow you to precisely regulate both pressure and speed, enabling you to tailor each cycle to the specific job.

Ultimately, understanding that a press's maximum force is a hard limit allows you to select and operate equipment safely and effectively.

Summary Table:

| Factor | Description | Impact on Maximum Force |

|---|---|---|

| Maximum System Pressure | Highest safe pressure (PSI/bar) the hydraulic pump and seals can handle. | Directly limits the pressure variable in the Force = Pressure × Area equation. |

| Piston Surface Area | The size of the main piston/ram in the hydraulic cylinder. | A larger area multiplies the available pressure into a greater output force. |

| Structural Integrity | The strength of the press frame, columns, and bed. | The structure must withstand the force; exceeding tonnage risks catastrophic failure. |

| Hydraulic Power Unit | The pump's ability to deliver oil flow. | Governs the trade-off between maximum force and press speed (cycle time). |

Need a hydraulic forging press that perfectly matches your force and speed requirements?

At KINTEK, we specialize in providing robust laboratory equipment, including hydraulic presses designed for precision and durability. Our experts can help you select a press with the right tonnage and cycle time to optimize your material forming or production process.

Contact our team today to discuss your specific application and discover how KINTEK's solutions can enhance your lab's efficiency and safety.

Visual Guide

Related Products

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- What is the function of a bench-top laboratory hydraulic press for XRF? Maximize Accuracy in Prosopis juliflora Analysis

- Why is a laboratory hydraulic press required during the preparation of Ti3AlC2 precursor pellets?

- What is the purpose of a laboratory hydraulic press for LATP electrolyte pellets? Achieve Optimal Density & Conductivity

- What core conditions does a laboratory hydraulic press provide for solid-state electrolyte pellets? Enhance Density!

- What is KBr disc method? A Complete Guide to IR Spectroscopy Sample Prep