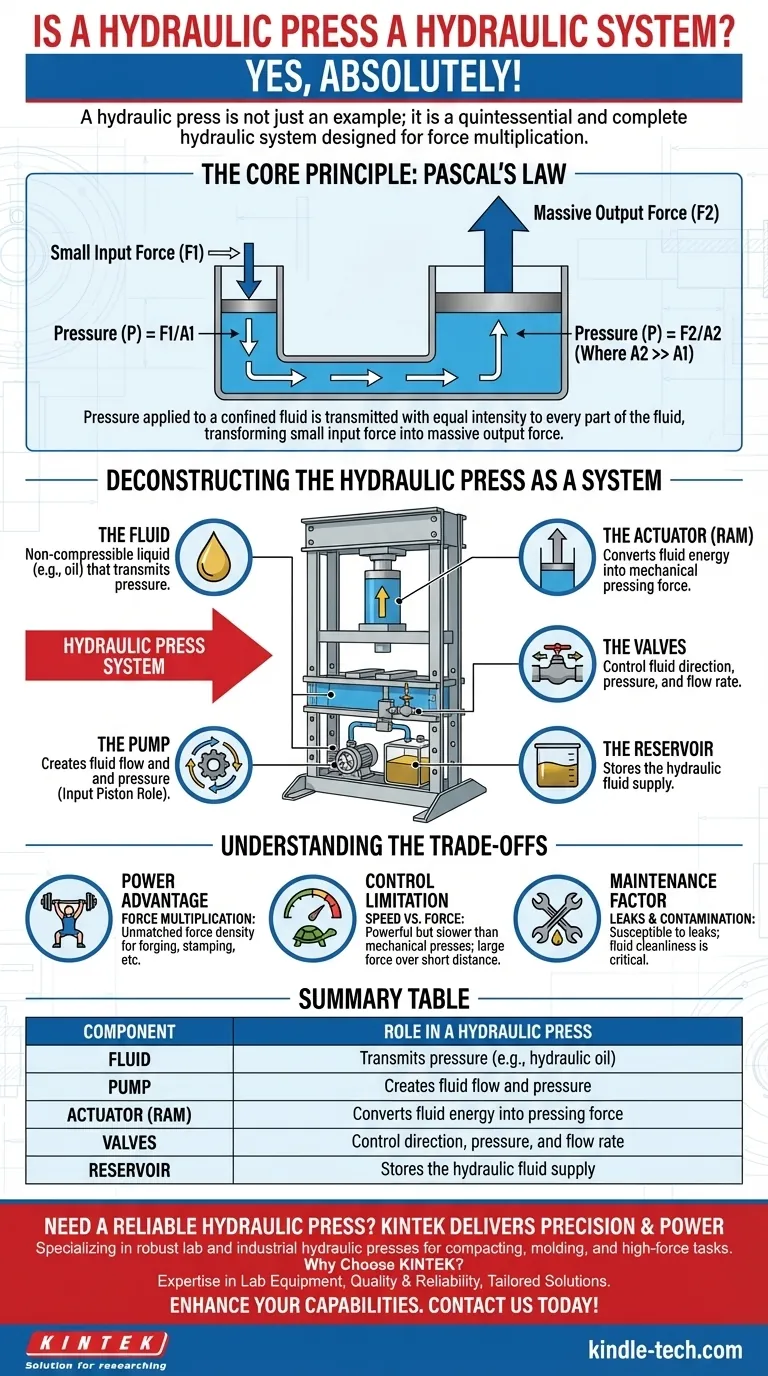

Yes, absolutely. A hydraulic press is not just an example of a hydraulic system; it is a quintessential and complete hydraulic system designed for a specific purpose. It perfectly demonstrates the core principle of using a confined, incompressible fluid to transmit and multiply force.

The key insight is that a hydraulic press isn't merely a component that uses hydraulics. It is a self-contained system that incorporates every necessary element—pump, fluid, actuator, and controls—to leverage Pascal's Law and generate immense compressive force.

What Defines a Hydraulic System?

To understand why a press fits the definition, we must first establish what constitutes a hydraulic system. At its core, any hydraulic system uses a fluid to transmit energy from one point to another to accomplish work.

The Core Principle: Pascal's Law

The foundational concept is Pascal's Law. This principle states that pressure applied to a confined and incompressible fluid is transmitted with equal intensity to every other part of the fluid.

This law is the "magic" that allows a small input force on a small piston to be transformed into a massive output force on a larger piston.

The Essential Components

Nearly all hydraulic systems are built from a common set of components working together:

- The Fluid: A non-compressible liquid, typically a specialized oil, that transmits the pressure.

- The Reservoir: A tank that holds the supply of hydraulic fluid.

- The Pump: A device that forces the fluid to flow, creating pressure within the system.

- The Actuator: The component that converts the fluid's energy into mechanical work. In a press, this is the main cylinder and ram.

- The Valves: Devices that control the fluid's direction, pressure, and rate of flow, allowing for precise operation.

Deconstructing the Hydraulic Press as a System

When you examine the anatomy of a hydraulic press, you can clearly identify each of the essential components of a complete hydraulic system.

The Input Piston (The Pump's Role)

A pump (which can be hand-operated or electric) applies force to a small piston. This action pressurizes the hydraulic fluid contained within the system's cylinders and hoses.

The Ram (The Actuator)

This pressurized fluid acts on a much larger piston, often called the ram. Because the surface area of the ram is significantly larger than the input piston, the force is multiplied dramatically according to Pascal's Law. This large, slow-moving ram is what performs the pressing action.

The Confined Fluid (The Medium)

The hydraulic oil fills the space between the pump and the ram. Its incompressibility is critical; it ensures that the energy put into the system isn't wasted by compressing the fluid itself but is instead transmitted directly to the actuator.

The Frame and Controls (The Complete Package)

The press also includes the heavy frame that withstands the immense forces, the reservoir to store the oil, and the valves that allow the operator to start, stop, and reverse the ram's movement. These elements bind the core components into a functional, self-contained machine.

Understanding the Trade-offs

Recognizing the press as a hydraulic system helps clarify the inherent advantages and disadvantages of this technology.

The Power Advantage: Force Multiplication

The primary benefit is unmatched force density. Hydraulic systems can generate enormous forces from relatively small and simple components, making them ideal for tasks like forging, stamping, and forming metal.

The Control Limitation: Speed vs. Force

There is an inverse relationship between force multiplication and distance traveled. The large ram multiplies the force, but it travels a much shorter distance than the small input piston. This makes hydraulic presses powerful but often slower than purely mechanical presses.

The Maintenance Factor: Leaks and Contamination

Like any hydraulic system, a press is susceptible to leaks at its seals and fittings. The performance of the system is also highly dependent on the cleanliness and quality of the hydraulic fluid, which requires regular monitoring and maintenance.

How This Applies to Your Understanding

Viewing the press through the lens of a complete system provides a clear framework for understanding hydraulic technology in any context.

- If your primary focus is grasping the basics of hydraulics: Use the hydraulic press as your core mental model; it is a perfect real-world application of Pascal's Law.

- If your primary focus is selecting equipment: Recognize that a hydraulic system like a press offers extreme power for heavy-duty tasks but may not be the right choice for high-speed, repetitive operations.

- If your primary focus is troubleshooting a machine: Remember that the press is a system of interconnected parts; a failure could be due to the pump, the fluid, the control valves, or the actuator seals, not just the ram itself.

By seeing the hydraulic press as a complete system, you unlock the fundamental principles that power countless other powerful machines across every major industry.

Summary Table:

| Component | Role in a Hydraulic Press |

|---|---|

| Fluid | Transmits pressure (e.g., hydraulic oil) |

| Pump | Creates fluid flow and pressure |

| Actuator (Ram) | Converts fluid energy into pressing force |

| Valves | Control direction, pressure, and flow rate |

| Reservoir | Stores the hydraulic fluid supply |

Need a Reliable Hydraulic Press for Your Lab or Workshop?

At KINTEK, we specialize in providing robust lab equipment, including hydraulic presses designed for precision and power. Whether you're compacting materials, molding, or performing other high-force tasks, our systems deliver unmatched performance and durability.

Why Choose KINTEK?

- Expertise in Lab Equipment: We understand the unique demands of laboratory and industrial environments.

- Quality and Reliability: Our hydraulic presses are built to withstand rigorous use, ensuring long-term value.

- Tailored Solutions: We help you select the right equipment to meet your specific application needs.

Enhance your capabilities with a KINTEK hydraulic press. Contact us today for a consultation and discover the difference quality equipment can make!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- What is the role of laboratory hydraulic presses or CIP in LFP solid-state battery assembly? Expert Insights

- How does a laboratory hydraulic press contribute to the electrochemical performance testing of LiMOCl4? Achieve Density

- What is the sample size for XRF? Achieve Accurate Analysis with Proper Sample Prep

- How to prepare samples for XRF? Achieve Accurate and Repeatable Elemental Analysis

- What are the parts of a hydraulic press machine? A Guide to the Core Systems & Components

- How do you prepare a sample for XRD analysis? Achieve Accurate Crystal Structure Data

- What is the application of a laboratory hydraulic press in catalyst preparation? Optimize Your Cellulose Conversion

- How much weight can a hydraulic press? The Real Measure is Tonnage, Not Machine Weight