Yes, Chemical Vapor Deposition (CVD) is generally considered a costly process, particularly when compared to more conventional surface treatment methods. The primary drivers of this cost are not just the equipment itself, but the significant operational requirements, including high energy consumption, the use of hazardous materials, and the complex safety infrastructure needed to manage the entire process safely and effectively.

The high cost of CVD is a direct result of its demanding process environment. The investment is driven by the need for high temperatures, the management of toxic or flammable precursor gases, and the extensive safety systems required for operation.

What Drives the Cost of CVD?

To understand if CVD is the right choice, you must first understand the specific factors contributing to its overall expense. The cost is multifaceted, extending far beyond the initial purchase of a deposition chamber.

High Energy Consumption

CVD operates at elevated temperatures, often requiring the entire substrate to be heated uniformly within the reaction chamber. This process is highly energy-intensive, leading to significant ongoing operational costs. This sustained high heat also introduces the risk of thermal stress in the coated part.

Hazardous Precursor Materials

The process relies on precursor reactant gases, many of which are highly toxic, flammable, or corrosive. These materials have inherent costs related to their production, purification, and specialized handling requirements. The supply chain for these gases can be complex and expensive.

Essential Safety and Environmental Infrastructure

Due to the hazardous nature of the precursor materials, a substantial investment in safety is non-negotiable. This includes specialized gas handling cabinets, leak detection and monitoring systems, emergency shutdown protocols, and robust ventilation and abatement systems to treat exhaust gases. These systems represent a significant portion of the total capital expenditure.

Process Complexity and Expertise

CVD is a complex process that demands precise control over temperature, pressure, and gas flow rates to achieve the desired coating properties. Operating and maintaining this equipment requires highly skilled engineers and technicians, which increases labor costs and the potential for downtime if not managed correctly.

Understanding the Trade-offs: Why Choose CVD Despite the Cost?

If CVD is so expensive and complex, its widespread use indicates it must offer significant advantages. The decision to use CVD is an engineering trade-off, balancing higher costs against superior performance.

Unmatched Coating Quality and Purity

The primary reason to invest in CVD is the quality of the result. CVD coatings are known for being exceptionally pure, dense, and impervious. They are fine-grained and typically harder than similar materials produced through other methods, providing superior wear and corrosion resistance.

Superior Uniformity on Complex Shapes

CVD is a gas-phase process, meaning the precursor gases can penetrate and coat intricate geometries and internal surfaces with exceptional uniformity. This "throwing power" is a key advantage over line-of-sight processes like Physical Vapor Deposition (PVD), which struggle with complex shapes.

When It's the Only Option

For certain advanced materials, CVD is not just the best method—it is the only viable method. Some high-performance coatings, such as specific ceramic or crystalline films, can only be synthesized through the unique chemical reactions that occur in a CVD process. In these cases, the cost is a necessary investment to achieve the required material properties.

Making the Right Choice for Your Goal

Your decision must be based on a clear understanding of your project's non-negotiable requirements.

- If your primary focus is achieving the highest possible performance and purity: The superior quality, density, and uniformity of CVD coatings often justify the significant investment.

- If your primary focus is minimizing cost and operational complexity: You should evaluate alternative methods like PVD, electroplating, or thermal spray, which may offer a more economical solution for less demanding applications.

- If your application requires a specific material only achievable via CVD: The cost becomes a necessary project requirement that must be budgeted for, as no other process can deliver the result.

Ultimately, choosing CVD is an informed decision where the high cost is weighed against the unparalleled performance and unique capabilities it provides.

Summary Table:

| Cost Factor | Key Drivers | Impact on Total Cost |

|---|---|---|

| High Energy Consumption | Sustained, uniform high-temperature operation | Significant ongoing operational expense |

| Hazardous Precursor Materials | Toxic, flammable, or corrosive gases; complex supply chain | High material and specialized handling costs |

| Safety & Environmental Systems | Gas cabinets, monitoring, ventilation, and exhaust abatement | Major capital expenditure (CapEx) |

| Process Complexity & Expertise | Precise control requirements; skilled operators needed | High labor costs and potential for downtime |

Ready to determine if CVD is the right investment for your lab's specific coating challenges?

At KINTEK, we specialize in providing advanced lab equipment and consumables for demanding applications. Our experts can help you analyze your requirements for coating purity, uniformity, and material performance to determine the most effective and efficient solution for your needs.

Contact our team today for a personalized consultation and discover how KINTEK can support your laboratory's pursuit of superior results.

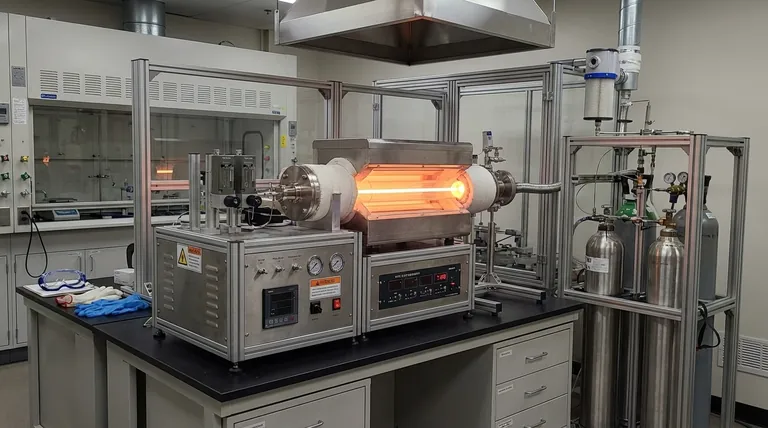

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What are the methods of deposition? A Guide to PVD and CVD Thin-Film Techniques

- How does PECVD work? Enable Low-Temperature, High-Quality Thin Film Deposition

- What are the steps of the CVD process? A Guide to Precision Thin Film Deposition

- What is PECVD in semiconductor? Enable Low-Temperature Thin Film Deposition for ICs

- What is the process of vacuum vapor deposition? Mastering CVD and PVD Thin-Film Coating