For daily wear and tear, gold PVD is better than gold filled due to its superior surface hardness and scratch resistance. The PVD process creates an exceptionally durable coating that is molecularly bonded to the base metal. However, gold-filled jewelry contains a much thicker, pressure-bonded layer of solid gold, giving it a higher intrinsic value and a finish that is virtually indistinguishable from solid gold.

The core difference is one of philosophy: PVD prioritizes modern, high-tech surface durability, while gold-filled prioritizes a traditional, substantial quantity of precious metal. Your choice depends on whether you value surface resilience or the amount of actual gold.

What is Gold PVD? The Modern Approach to Durability

Physical Vapor Deposition (PVD) is an advanced coating process conducted in a vacuum. It's a technology originally developed for aerospace and medical applications, prized for its ability to create exceptionally tough and pure surface layers.

How the PVD Process Works

In this process, a solid material (in this case, a gold alloy) is vaporized into a plasma of atoms or molecules. This vapor is then deposited onto the base metal (typically stainless steel), forming a new, thin film that is molecularly bonded to the surface.

This isn't a simple layer sitting on top; it's an integrated part of the surface. This molecular bond is what gives PVD its signature hardness and resilience.

Key Advantages of PVD

The primary benefit of PVD is superior wear and corrosion resistance. The resulting surface is significantly harder than standard gold plating or even the base metal itself, making it highly resistant to scratches and tarnishing from sweat or saltwater.

The process is also environmentally friendly, non-toxic, and produces an extremely pure and uniform coating, which is why it's trusted for medical devices.

What is Gold Filled? The Traditional Standard of Quality

Gold-filled is not a process in the same way as PVD; it's a regulated industry standard for creating a specific type of composite material. It has been used for over a century as a high-quality, affordable alternative to solid gold.

How Gold Filled is Made

Gold-filled jewelry is created by taking one or more thick sheets of solid gold and bonding them to a core of high-quality jewelers' brass using intense heat and pressure. This is a mechanical bond, not a molecular one.

The result is a thick, durable outer layer of real gold that will not flake, peel, or easily wear off.

The "1/20 14k" Standard

By law, gold-filled items must contain at least 5% (or 1/20th) of their total weight in solid gold. This is a significant amount of gold, far more than in any plated or PVD-coated piece. This is why gold-filled jewelry has a much higher intrinsic value based on its precious metal content.

Understanding the Trade-offs

Neither option is universally "better"; they excel in different areas. The right choice depends entirely on your priorities and how you plan to wear the jewelry.

The Priority of PVD: Surface Hardness

The gold layer in a PVD coating is microscopically thin, often thinner than traditional plating. Its value comes not from the amount of gold but from the process that makes the surface incredibly tough. It is designed to resist the abuses of daily life.

The Priority of Gold Filled: Gold Content

The gold layer on a gold-filled piece is dramatically thicker—often 50 to 100,000 times thicker than standard plating. While the gold itself is just as soft as solid gold, the sheer thickness of the layer means it would take decades of extreme wear to rub through to the brass core. Its value lies in the substantial quantity of gold.

Making the Right Choice for Your Goal

By focusing on your primary need, you can easily select the best option.

- If your primary focus is maximum scratch resistance for daily wear: Choose PVD. Its hardened surface is ideal for items like watches and rings that face constant friction.

- If your primary focus is long-term value and the look of solid gold: Choose gold-filled. It contains a significant amount of real gold and offers the same warm luster.

- If your primary focus is a budget-friendly but durable option: PVD is often more cost-effective, providing exceptional durability for its price point.

- If your primary focus is hypoallergenic properties: Both are excellent choices, as the material touching your skin is a high-quality, nickel-free gold alloy.

By understanding the difference between modern process and traditional material, you can confidently choose the gold jewelry that perfectly aligns with your lifestyle and values.

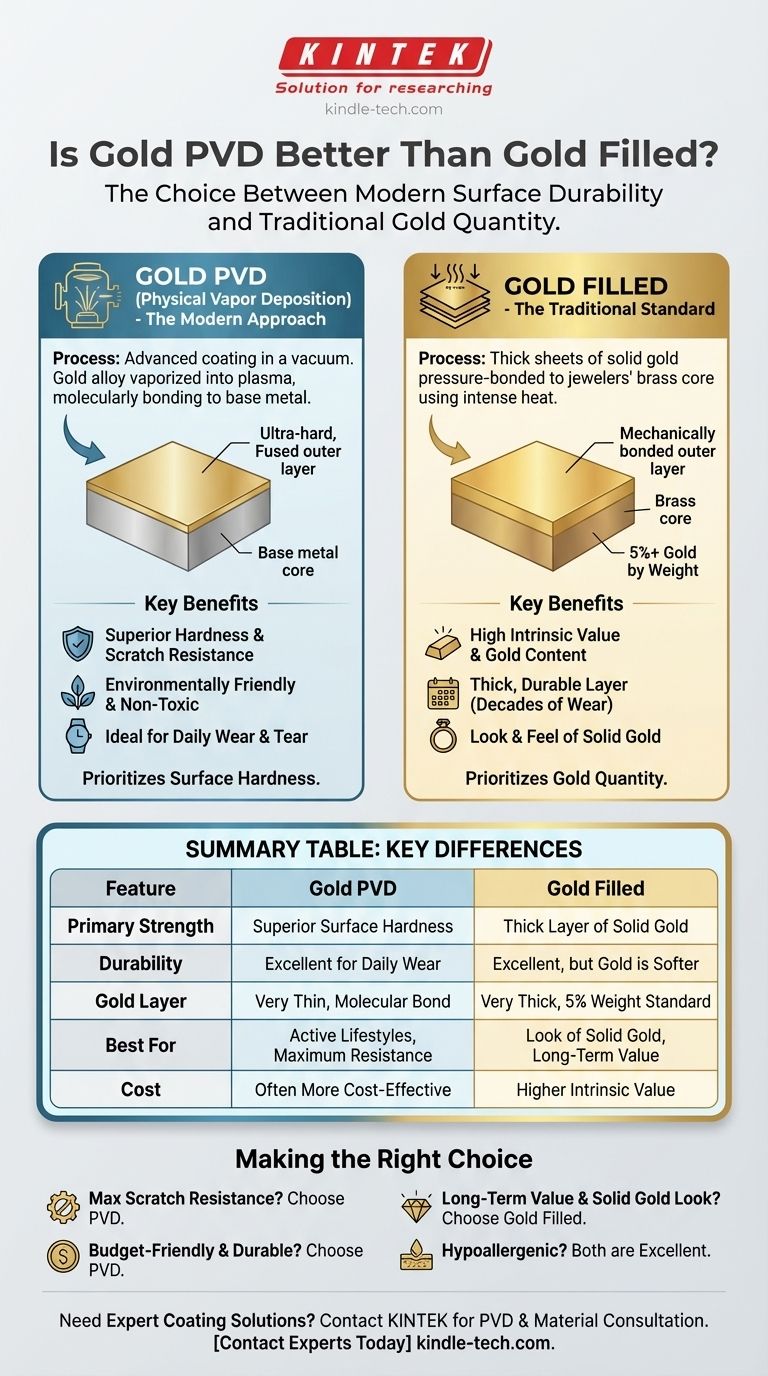

Summary Table:

| Feature | Gold PVD | Gold Filled |

|---|---|---|

| Primary Strength | Superior Surface Hardness & Scratch Resistance | Thick Layer of Solid Gold (High Intrinsic Value) |

| Durability | Excellent for daily wear and tear | Excellent, but the gold itself is softer |

| Gold Layer | Very thin, but molecularly bonded and hardened | Very thick (legally 5% of item's weight) |

| Best For | Active lifestyles, rings, watches, maximum scratch resistance | The look and feel of solid gold, long-term value |

| Cost | Often more cost-effective | Higher intrinsic value due to gold content |

Still Unsure Which Coating is Best for Your Project?

At KINTEK, we specialize in advanced coating technologies, including PVD, for a wide range of applications. Whether you're developing durable jewelry, precision instruments, or specialized lab equipment, our expertise can help you select the perfect surface solution.

We provide:

- Expert Consultation on material selection for durability, corrosion resistance, and aesthetics.

- High-Quality PVD Coatings that enhance product longevity and performance.

- Solutions Tailored to the unique demands of laboratory and industrial environments.

Let's discuss how our coatings can add value and durability to your products. Contact our experts today for a personalized consultation!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- CVD Diamond Cutting Tool Blanks for Precision Machining

People Also Ask

- What is hot press lamination? The Ultimate Guide to Strong, Durable Material Bonding

- What is hot press moulding? Achieve Superior Density and Complex Shapes with Heat and Pressure

- What is vacuum lamination? Achieve a Flawless, Durable Finish on Complex Shapes

- What is the advantage by using hot press forming? Achieve Stronger, More Complex Parts

- What are the advantages and disadvantages of hot stamping? Unlock Ultra-High Strength for Automotive Parts