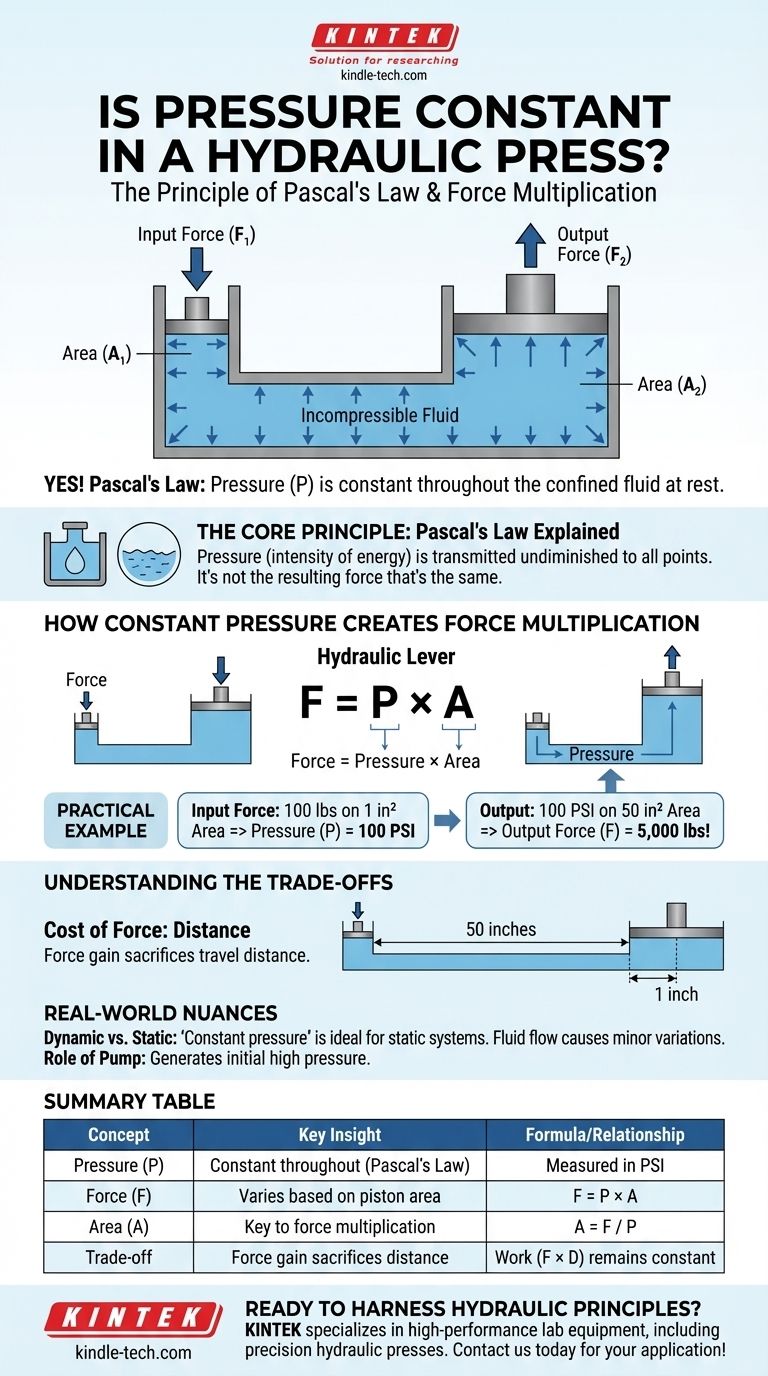

Yes, in an ideal hydraulic press at rest, the pressure is constant throughout the confined fluid. This principle, known as Pascal's Law, is the very reason a hydraulic press can function. The common confusion arises not from the pressure itself, but from how that uniform pressure generates vastly different forces on different-sized pistons.

The core insight is that while pressure remains constant throughout the fluid, the force produced is directly proportional to the area over which that pressure acts. A hydraulic press multiplies force by applying the same pressure to a much larger area.

The Core Principle: Pascal's Law Explained

At the heart of every hydraulic press is a fundamental rule of fluid dynamics. Understanding this rule is key to demystifying how it works.

A Contained and Incompressible Fluid

A hydraulic system relies on a fluid (typically oil) that is incompressible. This means when you apply pressure, the fluid's volume does not shrink.

Instead of being compressed, the fluid efficiently transmits the energy applied to it throughout the entire contained system.

Transmitting Pressure, Not Force

Pascal's Law states that a change in pressure at any point in a confined fluid is transmitted undiminished to all points throughout the fluid.

Think of pressure (measured in pounds per square inch or PSI) as the intensity of the energy. The law guarantees this intensity is the same everywhere in the system. It does not say the resulting force is the same.

How Constant Pressure Creates Force Multiplication

The genius of the hydraulic press is in its clever exploitation of Pascal's Law. It converts constant pressure into a powerful mechanical advantage.

The "Hydraulic Lever" Analogy

A hydraulic press acts like a "hydraulic lever." Instead of a physical lever arm, it uses the surface area of its pistons to create a mechanical advantage.

A small force is applied to a small "input" piston, which creates pressure in the fluid. This same pressure then pushes on a much larger "output" piston, generating a massive force.

The Fundamental Formula: F = P x A

The relationship is defined by a simple formula: Force = Pressure × Area (F = P × A).

Because the pressure (P) is constant everywhere in the fluid, the force (F) exerted by the fluid is determined entirely by the area (A) of the piston it is acting upon.

A Practical Example

Imagine you apply a 100-pound force to an input piston with a surface area of 1 square inch.

- Pressure (P) = Force / Area = 100 lbs / 1 in² = 100 PSI.

Now, this 100 PSI of pressure is transmitted throughout the fluid. It pushes on an output piston with an area of 50 square inches.

- Force (F) = Pressure × Area = 100 PSI × 50 in² = 5,000 pounds.

Your initial 100-pound push has been multiplied into a 5,000-pound compressive force, all because the pressure remained constant.

Understanding the Trade-offs and Real-World Nuances

While the principle is straightforward, real-world systems have important considerations that go beyond the ideal model.

The Cost of Force: Distance

There is no free lunch in physics. The force multiplication comes at the expense of distance.

To move the large 50-square-inch piston up by 1 inch, you must displace 50 cubic inches of fluid. To do this, you would have to push the small 1-square-inch piston down by a full 50 inches. You gain force but sacrifice travel distance.

Dynamic vs. Static Pressure

The "constant pressure" rule applies perfectly to a static system, meaning one that is not in motion.

When the press is operating and fluid is flowing, minor pressure differences can occur due to fluid friction against the pipe walls and turbulence. However, for understanding the core principle of force multiplication, these effects are negligible.

The Role of the Pump

The initial pressure is not created from nothing. A hydraulic pump, powered by an electric motor or engine, does the work to generate the high pressure within the fluid, which the press then uses to multiply force.

Applying This Principle

Understanding this distinction between pressure and force is critical for anyone working with mechanical or fluid systems. Your focus will depend on your goal.

- If your primary focus is to understand how force is multiplied: Concentrate on the formula F = P × A and recognize that the difference in piston area is the key to the entire system.

- If your primary focus is to design or troubleshoot a system: Remember that the "constant pressure" model is an ideal and you must account for the trade-off between force and distance, as well as energy losses from fluid friction in a dynamic system.

By mastering the relationship between pressure, force, and area, you unlock the fundamental principle behind all hydraulic power.

Summary Table:

| Concept | Key Insight | Formula / Relationship |

|---|---|---|

| Pressure (P) | Constant throughout the confined fluid (Pascal's Law) | Measured in PSI (pounds per square inch) |

| Force (F) | Varies based on the piston area it acts upon | F = P × A |

| Area (A) | The key to force multiplication; larger area = greater force | A = F / P |

| Trade-off | Force gain comes at the expense of travel distance | Work (Force × Distance) remains constant |

Ready to harness the power of hydraulic principles in your lab?

KINTEK specializes in high-performance lab equipment, including hydraulic presses designed for precision and reliability. Whether you need consistent pressure for material testing, sample preparation, or industrial research, our solutions are engineered to deliver accurate force multiplication for your specific laboratory needs.

Contact us today to find the perfect hydraulic press for your application and experience the KINTEK difference in quality and support.

Get in touch with our experts now!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Manual Lab Heat Press

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- What role does a laboratory hydraulic press play in the preparation of solid electrolyte pellets? Ensure Data Accuracy

- Are hydraulic presses powered by water? Discover the critical role of hydraulic oil.

- Why are KBr pellets used in FTIR? Achieve Clear, Accurate Solid Sample Analysis

- What is the use of KBr? Master Sample Prep for Accurate IR Spectroscopy

- What is the pressed powder pellet method? A Guide to Accurate FTIR Sample Preparation