In short, yes. For the end-user, products with a Physical Vapor Deposition (PVD) coating are exceptionally safe. The process creates a finish that is molecularly bonded to the base material, making it incredibly durable, non-reactive, and unlikely to chip, flake, or wear away.

The safety of a PVD coating stems directly from its process. By fusing a thin layer of inert material to a surface at the atomic level, the final product becomes highly durable and chemically stable, posing no risk in everyday use. The primary health considerations are limited to the industrial application phase, not the finished item.

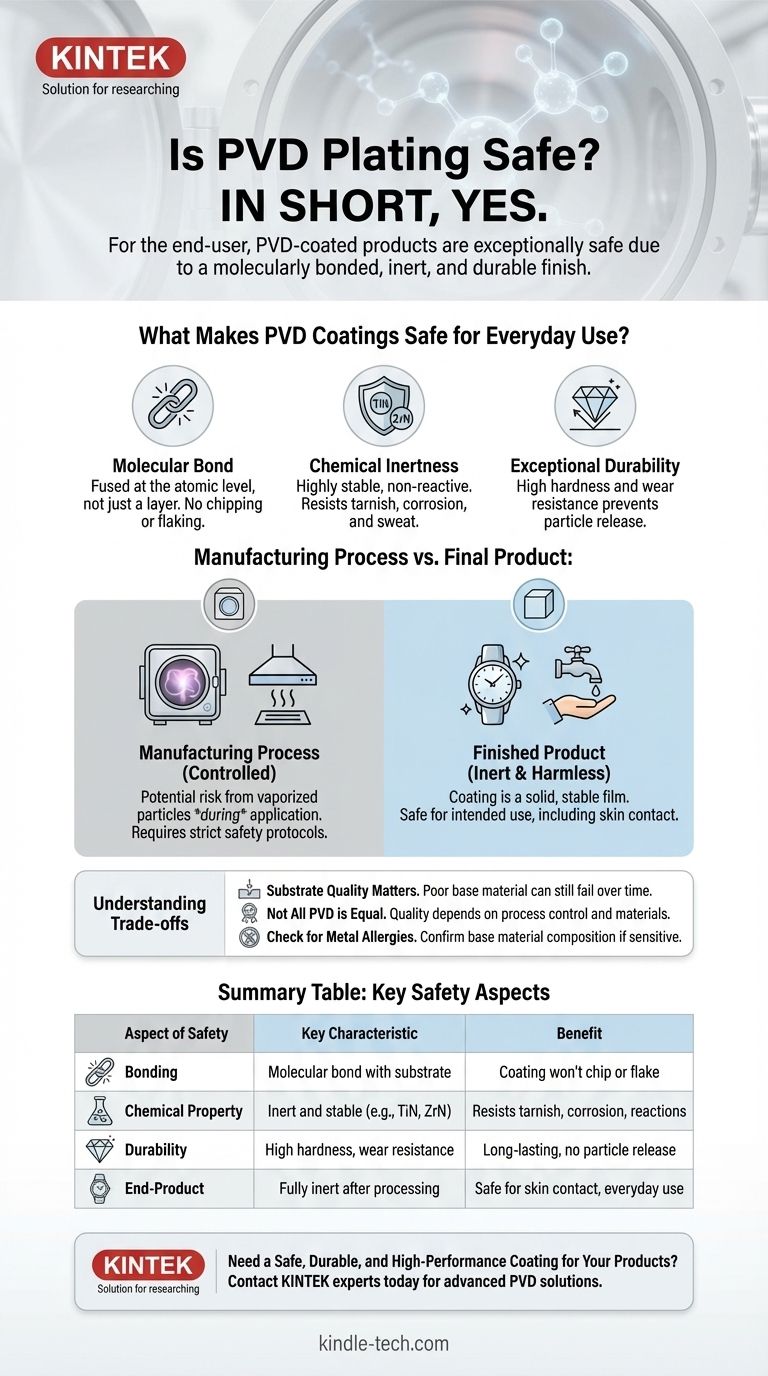

What Makes PVD Coatings Safe for Everyday Use?

The safety of a PVD-coated item isn't an accident; it's a direct result of the sophisticated scientific process used to create it. It differs fundamentally from traditional plating or painting.

A Molecular Bond, Not Just a Layer

The PVD process takes place in a high-tech vacuum chamber. The coating material is vaporized into a plasma of atoms or ions, which are then accelerated toward the product's surface.

This doesn't just "paint" the surface; it creates a molecular bond between the coating and the substrate. The new layer is fused onto the original material, making it an integral part of the product.

Chemical Inertness and Stability

PVD coatings are prized for their resistance to chemical reactions. The materials used, such as titanium nitride or zirconium nitride, are chosen for their stability.

This inertness means the coating will not tarnish or corrode when exposed to sweat, detergents, or other chemicals. This is why PVD is trusted for items with high skin contact, like jewelry and watches, as well as kitchen and bath fixtures.

Exceptional Durability and Wear Resistance

A coating can only be safe if it stays where it belongs. The high hardness and strong adhesion of PVD finishes make them incredibly resistant to scratches, abrasion, and daily wear.

Because the coating doesn't easily chip or flake, there is no mechanism for it to release particles onto your skin or into the environment. Its durability is a core component of its safety.

Manufacturing Process vs. Final Product

It's critical to distinguish between the safety of the finished product you hold in your hand and the industrial process used to make it.

The Finished Product: Inert and Harmless

Once the PVD process is complete, the coated item is fully inert. The particles of the coating material are locked into a solid, stable film and cannot become airborne or leach out.

For the consumer, this means the product is safe for its intended use, whether it's a tool, a faucet, a medical device, or a piece of jewelry.

The Application Process: A Controlled Environment

The potential health risks associated with PVD exist exclusively within the manufacturing environment. During the application process, inhaling the vaporized coating particles before they bond to the substrate can be hazardous.

This is why PVD coating is performed in a sealed vacuum chamber by trained professionals who follow strict industrial safety protocols to prevent exposure.

Understanding the Trade-offs

While PVD offers exceptional safety and durability, no technology is without its considerations. Understanding them gives you a complete picture.

Substrate Quality Matters

A PVD coating is a surface finish. While it is incredibly durable, a poor-quality base material can still be a point of failure. Over many years of extreme use, deep scratches or wear could theoretically expose the substrate underneath.

If you have a known metal allergy, such as to nickel, it is always wise to confirm the composition of the base metal, not just the coating.

Not All PVD is Created Equal

The final quality of a PVD finish depends heavily on the manufacturer's process control, the specific materials used, and the thickness of the application. A thinly or improperly applied coating will not offer the same level of durability and long-term stability.

Choosing products from reputable manufacturers ensures the PVD process was executed correctly, guaranteeing both performance and safety.

How to Assess PVD Safety for Your Needs

Your perspective on PVD safety depends on your goal. Use these guidelines to make an informed decision.

- If your primary focus is choosing a consumer product (e.g., watch, faucet, jewelry): A properly applied PVD coating is inert, durable, and completely safe for skin contact and general household use.

- If your primary focus is manufacturing: Your safety responsibility is to protect workers from inhaling vaporized materials during the application process by ensuring strict adherence to industrial safety protocols.

- If your primary focus is avoiding allergies: PVD coatings themselves are generally hypoallergenic, but you should confirm the base material underneath if you have a severe sensitivity to specific metals.

Ultimately, the modern PVD process yields a finished product whose safety and stability are integral to its superior performance.

Summary Table:

| Aspect of Safety | Key Characteristic | Benefit |

|---|---|---|

| Bonding | Molecular bond with substrate | Coating won't chip or flake |

| Chemical Property | Inert and stable (e.g., TiN, ZrN) | Resists tarnish, corrosion, and skin reactions |

| Durability | High hardness and wear resistance | Long-lasting finish with no particle release |

| End-Product | Fully inert after processing | Safe for skin contact and everyday use |

Need a Safe, Durable, and High-Performance Coating for Your Products?

At KINTEK, we specialize in advanced PVD coating solutions for a wide range of applications, from precision tools and medical devices to consumer goods. Our expertise ensures a molecularly bonded, inert finish that guarantees product safety and longevity.

Let us help you enhance your product's value with a coating that is as safe as it is durable. Contact our experts today to discuss your specific lab equipment and consumable needs!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- What are the benefits of PECVD? Achieve Superior Low-Temperature Thin Film Deposition

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- What are the advantages of PECVD? Enable Low-Temperature, High-Quality Thin-Film Deposition

- What is an example of PECVD? RF-PECVD for High-Quality Thin Film Deposition

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings