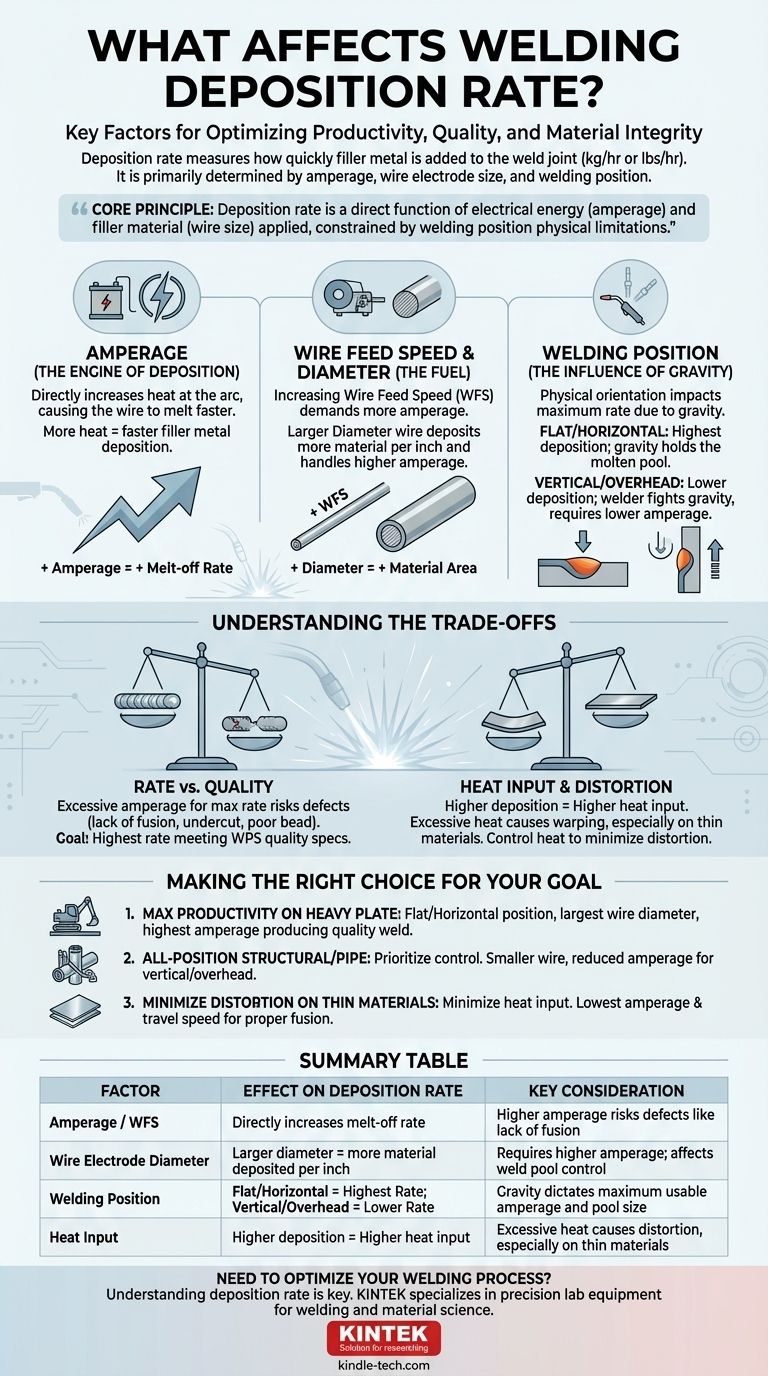

In welding, the deposition rate is primarily determined by the amperage, the size of the wire electrode, and the welding position. These factors work together to control how quickly filler metal is melted and added to the weld joint, which is typically measured in kilograms or pounds per hour.

The core principle is straightforward: deposition rate is a direct function of how much electrical energy you apply (amperage) and how much filler material you can effectively deliver (wire size), all constrained by the physical limitations of the welding position.

The Core Drivers of Deposition Rate

To effectively control and optimize your welding process, you must understand how each primary variable influences the outcome. These factors are not independent; they are interconnected aspects of a single system.

Amperage (The Engine of Deposition)

Amperage, or electrical current, is the most significant factor influencing the melt-off rate of the wire electrode. Think of it as the engine driving the entire process.

Increasing the amperage directly increases the amount of heat generated at the arc, causing the wire to melt faster. This results in more filler metal being deposited into the weld joint over a given period.

Wire Feed Speed and Diameter (The Fuel)

In modern semi-automatic processes like GMAW (MIG), amperage is directly tied to the wire feed speed (WFS). Increasing the WFS demands more amperage from the power source to melt the wire as it's fed.

The diameter of the wire electrode also plays a critical role. A larger diameter wire has more cross-sectional area, meaning more material is deposited for every inch of wire fed into the weld. Larger wires can also handle higher amperages, further compounding their effect on the deposition rate.

Welding Position (The Influence of Gravity)

The physical orientation of the weld has a profound impact on the maximum achievable deposition rate. This is primarily due to the effects of gravity on the molten weld pool.

Flat and horizontal positions allow for the highest deposition rates. In these positions, gravity helps to hold the molten metal in the joint, allowing the welder to use higher amperage and create a larger weld pool without it dripping or sagging.

Conversely, vertical and overhead positions force the welder to fight against gravity. This necessitates using lower amperage settings to keep the weld pool small and manageable, which inherently reduces the deposition rate.

Understanding the Trade-offs

Simply aiming for the highest possible deposition rate is a common but misguided goal. True optimization requires balancing speed with quality and control.

Rate vs. Quality

Pushing for maximum deposition by excessively increasing amperage can introduce serious weld defects. These can include lack of fusion, undercut, or poor bead appearance, all of which compromise the integrity of the weld.

The objective is to find the highest deposition rate that consistently meets the required quality specifications defined by the welding procedure specification (WPS).

Heat Input and Distortion

A higher deposition rate, driven by high amperage, directly translates to higher heat input into the base material. Excessive heat can cause significant warping and distortion, especially on thinner materials.

Controlling heat input is often a more critical goal than maximizing speed, as correcting distortion can be far more costly and time-consuming than the initial welding.

Making the Right Choice for Your Goal

The ideal deposition rate is not a single number but a target based on the specific demands of the job. Use these principles to guide your setup.

- If your primary focus is maximum productivity on heavy plate: Weld in the flat or horizontal position, use the largest practical wire diameter for the joint, and set the amperage to the highest level that still produces a quality weld.

- If your primary focus is all-position structural or pipe welding: Prioritize weld pool control. This means accepting a lower deposition rate by using smaller diameter wires and reduced amperage, especially for vertical and overhead passes.

- If your primary focus is minimizing distortion on thin materials: The goal is to minimize heat input. Use the lowest possible amperage and travel speed that still achieves proper fusion, resulting in a low deposition rate.

Mastering these variables allows you to move beyond simply joining metal and begin engineering the most efficient and effective outcome for any welding challenge.

Summary Table:

| Factor | Effect on Deposition Rate | Key Consideration |

|---|---|---|

| Amperage / Wire Feed Speed | Directly increases melt-off rate | Higher amperage risks defects like lack of fusion |

| Wire Electrode Diameter | Larger diameter = more material deposited per inch | Requires higher amperage; affects weld pool control |

| Welding Position | Flat/Horizontal = Highest Rate; Vertical/Overhead = Lower Rate | Gravity dictates maximum usable amperage and pool size |

| Heat Input | Higher deposition = Higher heat input | Excessive heat causes distortion, especially on thin materials |

Need to Optimize Your Welding Process?

Understanding deposition rate is key to balancing productivity, quality, and material integrity. The right lab equipment is essential for developing and validating your welding procedures.

KINTEK specializes in supplying precision lab equipment and consumables that support material testing and process development. Whether you're researching new techniques or ensuring quality control, we provide the reliable tools your laboratory needs.

Contact our experts today to discuss how KINTEK can support your laboratory's welding and material science challenges.

Visual Guide

Related Products

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Metallographic Specimen Mounting Machine for Laboratory Materials and Analysis

People Also Ask

- How is something diamond coated? A Guide to CVD Growth vs. Plating Methods

- What machine is used to make lab-grown diamonds? Discover the HPHT & CVD Technologies

- How do CVD diamonds grow? A Step-by-Step Guide to Lab-Grown Diamond Creation

- What is the process of coating deposition? A Step-by-Step Guide to Thin Film Engineering

- What is microwave plasma CVD? A Guide to High-Purity Diamond and Material Synthesis