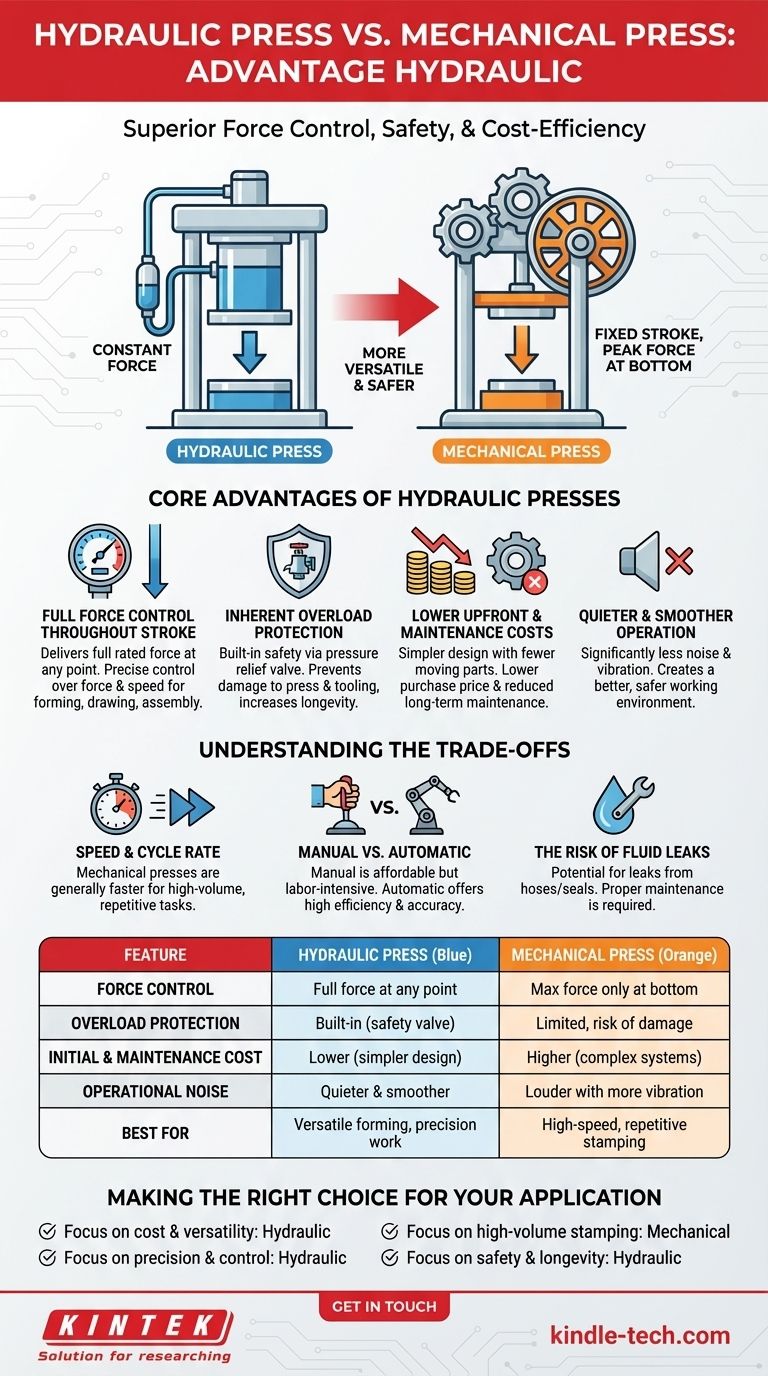

In essence, a hydraulic press offers significant advantages over a mechanical press primarily in its superior force control, built-in overload protection, and lower operational and maintenance costs. This is due to its simpler design, which uses fluid pressure to generate force, resulting in fewer moving parts and a more adaptable operating profile.

The fundamental difference lies in how force is delivered. A mechanical press offers high speed with a fixed stroke, while a hydraulic press provides constant, precisely controllable force throughout its entire stroke, making it more versatile and safer for a wider range of applications.

The Core Advantages of Hydraulic Presses Explained

To understand why a hydraulic press is often the preferred choice, we must look at its core operating principles and how they translate into tangible benefits.

Full Force Control Throughout the Stroke

A hydraulic press can deliver its full rated force at any point in the ram's stroke. This is a critical distinction from mechanical presses, which only achieve maximum force at the very bottom of their stroke.

This constant pressure allows for precise control over force and speed, which is essential for applications requiring deep drawing, forming, or delicate assembly operations.

Inherent Overload Protection

The system's maximum pressure can be set, meaning the press will never exert more force than it's rated for. This is accomplished through a pressure relief valve.

This feature provides built-in protection for the press and the tooling, preventing damage from overloads that can be catastrophic in a mechanical press. This safety feature significantly increases the machine's longevity.

Lower Upfront and Maintenance Costs

Hydraulic presses have a simpler design with fewer moving parts compared to the complex gear, crank, and flywheel systems of mechanical presses.

This simplicity translates to a lower purchase price and reduced long-term maintenance costs. With fewer components subject to wear, breakdowns are less frequent and repairs are typically more straightforward.

Quieter and Smoother Operation

The reduction in moving parts also means a hydraulic press operates with significantly less noise and vibration. This creates a better, safer working environment for operators.

Understanding the Trade-offs

While the advantages are compelling, it's crucial to understand the contexts where a hydraulic press may not be the optimal choice.

Speed and Cycle Rate

For high-volume, repetitive tasks like blanking or shallow stamping, mechanical presses are generally faster. Their fixed stroke length and flywheel-driven action allow for higher cycle rates than most hydraulic systems.

Manual vs. Automatic Operation

The choice within the hydraulic category itself presents a trade-off. Manual hydraulic presses are highly affordable but can be labor-intensive and less efficient for frequent use.

Automatic hydraulic presses, which use electricity to control the system, offer much higher efficiency, accuracy, and repeatability. They are ideal for labs or workshops with a high throughput of samples or parts.

The Risk of Fluid Leaks

As with any hydraulic system, there is a potential for fluid leaks from hoses or seals. While proper maintenance mitigates this risk, it remains a consideration for cleanliness and environmental safety.

Making the Right Choice for Your Application

Your final decision should be guided by the specific demands of your work, not by a simple "better or worse" comparison.

- If your primary focus is cost-effectiveness and versatility: A hydraulic press is the ideal choice due to its lower initial cost, reduced maintenance, and ability to handle a wide variety of tasks.

- If your primary focus is precision and process control: The ability to precisely manage force, speed, and dwell time makes a hydraulic press the superior option for forming, drawing, and assembly.

- If your primary focus is high-volume, repetitive stamping: A mechanical press often holds the advantage due to its faster cycle rates and efficiency in high-speed production lines.

- If your primary focus is operator safety and equipment longevity: The built-in overload protection of a hydraulic press prevents damage to expensive tooling and provides a safer operating environment.

Ultimately, selecting the right press requires matching its core operating principle to your specific production goals.

Summary Table:

| Feature | Hydraulic Press | Mechanical Press |

|---|---|---|

| Force Control | Full force at any point in stroke | Max force only at bottom of stroke |

| Overload Protection | Built-in (pressure relief valve) | Limited, risk of catastrophic damage |

| Initial & Maintenance Cost | Lower (simpler design) | Higher (complex gear/crank system) |

| Operational Noise | Quieter and smoother | Louder with more vibration |

| Best For | Versatile forming, deep drawing, precision work | High-speed, repetitive stamping |

Ready to enhance your lab's capabilities with the right press?

At KINTEK, we specialize in providing high-quality lab equipment, including hydraulic and mechanical presses tailored to your specific needs. Whether you require the precise force control and versatility of a hydraulic press for complex forming tasks or the high-speed efficiency of a mechanical press for repetitive operations, our experts are here to help you make the optimal choice.

Contact us today to discuss your application and discover how KINTEK's reliable solutions can improve your efficiency, safety, and bottom line.

Get in touch with our specialists now!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Manual Lab Heat Press

People Also Ask

- How hot is a hydraulic press? Understanding the Critical Heat in Your Hydraulic System

- Why are KBr pellets used in FTIR? Achieve Clear, Accurate Solid Sample Analysis

- Why use KBr for IR? Achieve Clear, Unobstructed Spectra for Solid Samples

- Are hydraulic presses powered by water? Discover the critical role of hydraulic oil.

- What role does a laboratory hydraulic press play in the preparation of solid electrolyte pellets? Ensure Data Accuracy