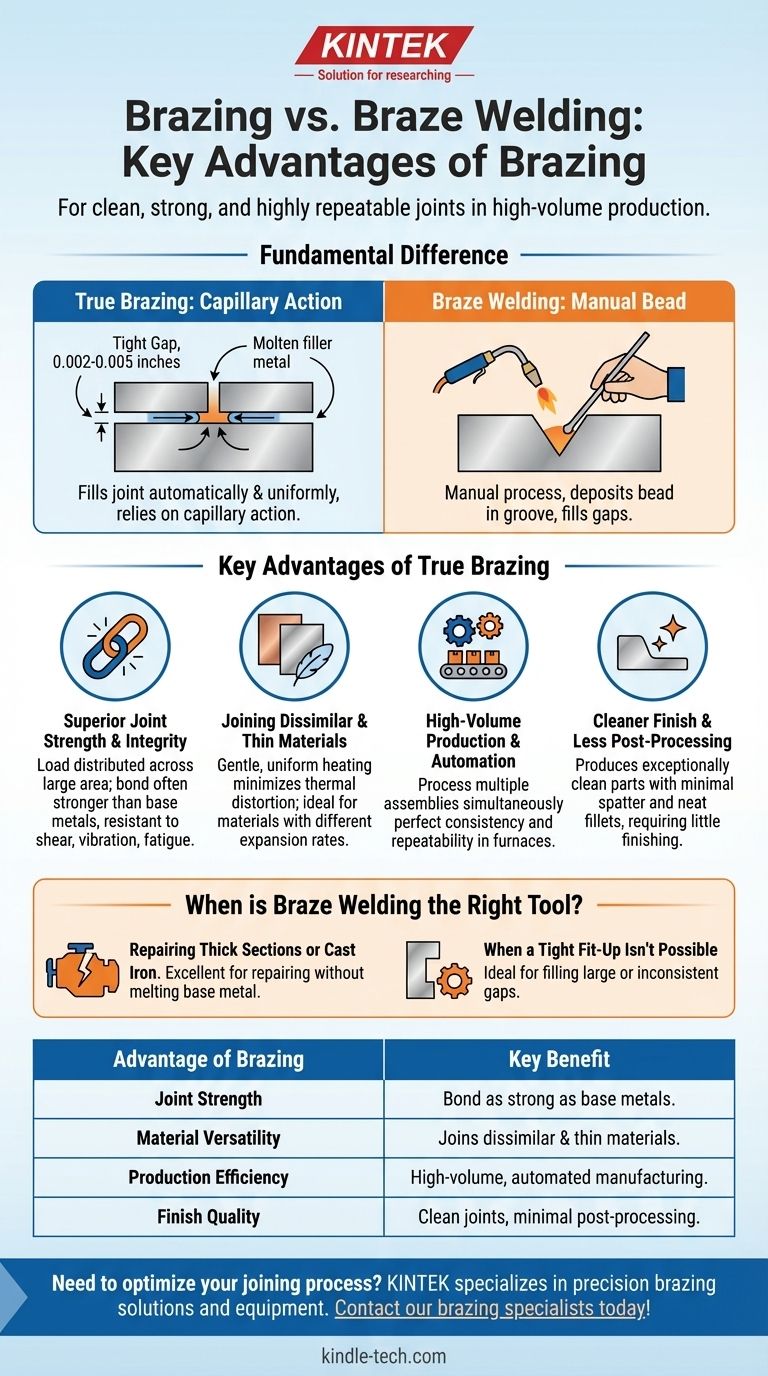

In short, the primary advantage of brazing is its ability to create clean, strong, and highly repeatable joints. It achieves this by using capillary action to draw a filler metal into a narrow gap between base metals, resulting in a bond that is often as strong as the materials being joined. This process excels in high-volume production, joining dissimilar or thin materials, and creating complex assemblies with minimal thermal distortion.

The fundamental difference lies in the method of application. True brazing relies on capillary action to fill a tight, uniform joint automatically, while braze welding is a manual process that deposits a filler metal bead into a groove or fillet, much like traditional welding. This core distinction dictates the strengths and ideal use cases for each process.

What is the Fundamental Difference?

To understand the advantages, we must first be precise about the terminology. While both processes use a filler metal and do not melt the base materials, how they form the joint is entirely different.

Brazing: The Power of Capillary Action

True brazing is a process defined by capillary action. The parts to be joined are designed with a very small, specific gap between them (typically 0.002 to 0.005 inches).

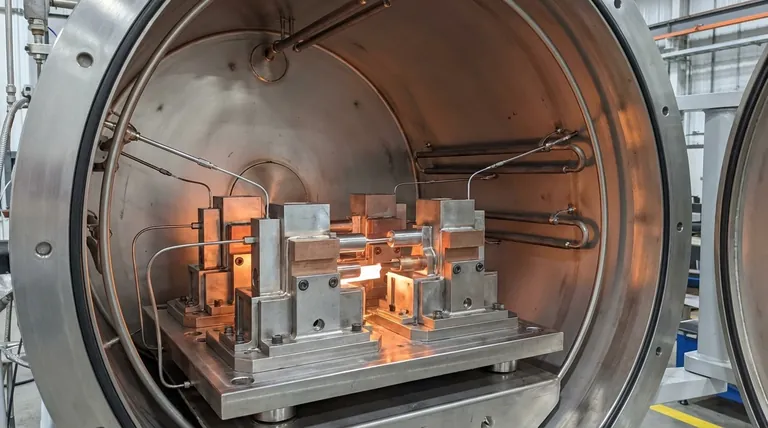

When heated, the molten filler metal is drawn into this gap, completely and uniformly filling the space between the two surfaces. This often occurs in a controlled environment like a furnace, which ensures even heating and a clean, flux-free finish.

Braze Welding: Building a Bead

Braze welding, by contrast, does not use capillary action. It functions much more like traditional arc or gas welding.

Heat is applied locally with a torch, and the filler metal (often a bronze rod) is manually deposited to form a fillet or bead in a groove or at the junction of the two parts. It's used to fill gaps, build up surfaces, or join parts that do not have a tight-fitting joint design.

Key Advantages of True Brazing

The reliance on capillary action gives brazing several distinct advantages over the manual bead deposition of braze welding.

Superior Joint Strength and Integrity

Because capillary action pulls the filler metal into the entire joint interface, the resulting bond is incredibly strong and free of voids. The load is distributed across a large surface area, not just a localized fillet.

This creates a joint that is often stronger than the parent metals themselves, with excellent resistance to shear, vibration, and fatigue.

Joining Dissimilar and Thin Materials

Brazing typically involves heating the entire assembly uniformly in a furnace. This gentle, controlled heating minimizes the risk of thermal shock or distortion, which is critical when joining metals with different expansion rates (e.g., copper to steel) or when working with thin-walled components.

Braze welding's localized, high-intensity heat can easily warp thin sections or create stress in dissimilar metal joints.

High-Volume Production and Automation

Furnace brazing is exceptionally well-suited for automation and high-volume manufacturing. Multiple assemblies, even complex ones with many joints, can be processed simultaneously with perfect consistency and repeatability.

Braze welding is a manual, labor-intensive process that is inherently slower and subject to operator-to-operator variation.

Cleaner Finish and Less Post-Processing

Brazing, especially vacuum brazing, produces an exceptionally clean part that requires little to no post-processing. There is no spatter, and the filler metal forms a neat, small fillet.

Braze welding leaves a large, visible bead that often requires grinding or other finishing operations to meet aesthetic or dimensional requirements.

When is Braze Welding the Right Tool?

Objectivity requires acknowledging that braze welding is not an inferior process, but a different tool for different jobs. Its manual, gap-filling nature makes it the superior choice in specific scenarios.

For Repairing Thick Sections or Cast Iron

Braze welding excels at repairing thick materials or cracked castings. It's an effective way to fill a prepared groove in a damaged part without having to melt the base metal, which is particularly important for difficult-to-weld materials like cast iron.

When a Tight Fit-Up Isn't Possible

Brazing's reliance on capillary action demands a precisely designed, tight-fitting joint. If you are joining parts with large or inconsistent gaps, braze welding is the only viable option between the two, as it is designed specifically to fill those gaps.

Making the Right Choice for Your Goal

Ultimately, the correct choice depends entirely on your application's design, material, and production volume.

- If your primary focus is high-volume production with strong, repeatable joints: True brazing is the definitive choice for its automation capabilities and superior joint integrity.

- If your primary focus is joining dissimilar metals or thin-walled components: Brazing provides the gentle, uniform heating needed to prevent distortion and stress.

- If your primary focus is manual repair or joining parts with poor fit-up: Braze welding is the appropriate tool for filling large, inconsistent gaps.

Choosing the right process begins with understanding that brazing and braze welding solve two fundamentally different engineering problems.

Summary Table:

| Advantage of Brazing | Key Benefit |

|---|---|

| Joint Strength | Capillary action creates a bond as strong as the base metals. |

| Material Versatility | Excellent for joining dissimilar metals and thin sections. |

| Production Efficiency | Ideal for high-volume, automated manufacturing. |

| Finish Quality | Produces clean joints with minimal post-processing. |

Need to optimize your joining process for strength, speed, and quality?

KINTEK specializes in precision brazing solutions and equipment for laboratories and manufacturers. Our expertise ensures your assemblies meet the highest standards for integrity and performance.

Contact our brazing specialists today to discuss your project requirements!

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

People Also Ask

- What is the difference between sintering and fusing? Master the Key Thermal Processes for Your Materials

- What are the materials for vacuum hardening? A Guide to High-Performance Steel Selection

- What is vacuum coating process? Achieve Superior Surface Performance with Thin-Film Technology

- How do you rejuvenate vacuum tubes? A Guide to Restoring Cathode Performance

- Where is vacuum casting used? A Bridge to High-Quality Prototypes and Low-Volume Production

- What is vacuum deposition? Achieve Unmatched Purity and Precision in Thin-Film Coatings

- What is annealing and why is it done? Achieve Softer, More Stable Materials

- Why would you want to anneal your metal? Restore Ductility and Improve Machinability