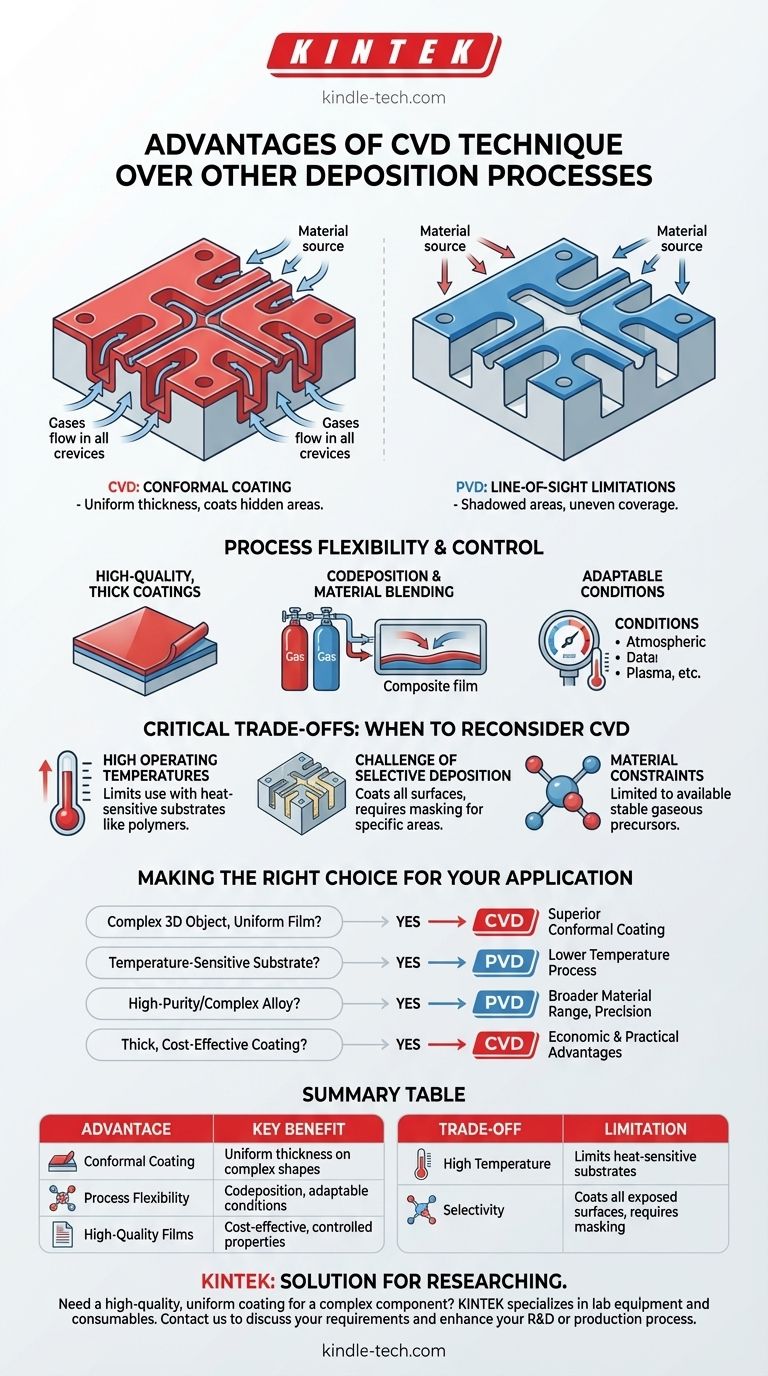

The fundamental advantage of Chemical Vapor Deposition (CVD) is its exceptional ability to produce highly uniform, or conformal, coatings over complex three-dimensional surfaces. Unlike methods that require a direct line of sight between the material source and the substrate, CVD uses gaseous precursors that can flow around and into intricate geometries, ensuring complete and even coverage.

The choice between CVD and other methods, like Physical Vapor Deposition (PVD), is a critical engineering decision. CVD excels at coating complex shapes uniformly, while PVD often provides a lower-temperature process suitable for a wider range of materials and heat-sensitive substrates.

The Defining Advantage: Conformal Coating

The core strength of CVD stems from its gas-phase reaction mechanism. This process is fundamentally different from the line-of-sight techniques that define most PVD methods.

Overcoming Line-of-Sight Limitations

In PVD processes like sputtering or evaporation, the coating material travels in a straight line from the source to the substrate. This can create "shadowed" areas on complex parts where the coating is thin or non-existent.

CVD completely avoids this issue. The precursor gases surround the substrate, allowing the chemical reaction that forms the film to occur on all exposed surfaces simultaneously.

Uniformity on Complex Geometries

This ability to coat every nook and cranny makes CVD the superior choice for objects with intricate patterns, deep trenches, or internal surfaces. The resulting film maintains a consistent thickness across the entire part, which is critical for performance in many semiconductor and industrial applications.

Process Flexibility and Control

Beyond its conformal nature, CVD offers significant flexibility in both the deposition process and the properties of the resulting film.

High-Quality, Thick Coatings

CVD is particularly well-suited for synthesizing thick coatings in a cost-effective manner. It also provides a high degree of control over material properties like composition, hardness, and conductivity by precisely managing the input gases and reaction conditions.

Codeposition and Material Blending

The process allows for the codeposition of different materials by introducing multiple precursor gases into the reaction chamber at the same time. This enables the creation of composite films and alloys with tailored properties.

Adaptable Operating Conditions

CVD techniques are highly adaptable. Some variations can operate at atmospheric pressure, while others use plasma or other initiators to improve reactivity and lower the required deposition temperature, expanding the range of possible applications.

Critical Trade-offs: When to Reconsider CVD

No deposition technique is perfect for every scenario. Understanding CVD's limitations is key to making an informed decision.

High Operating Temperatures

Traditional CVD processes require very high temperatures to drive the necessary chemical reactions. This limits the types of substrate materials that can be used, as many polymers or certain metals cannot withstand the heat without deforming or melting.

In contrast, PVD is a much lower-temperature process, making it the default choice for coating heat-sensitive products.

The Challenge of Selective Deposition

CVD's greatest strength—its ability to coat everything—is also a significant drawback. The process deposits the film anywhere the gas can reach, meaning extensive masking or post-coating grinding is often required to remove material from critical areas.

PVD offers a clear advantage here, as masks can be used to easily coat only the desired areas of a substrate.

Material and Purity Constraints

While flexible, CVD is limited to materials for which suitable, stable gaseous precursors exist. PVD techniques like sputtering can deposit a much broader range of materials, including complex alloys and mixtures, with exceptional purity and atomic-level precision.

Making the Right Choice for Your Application

The decision to use CVD must be based on the specific goals of your project, the nature of your substrate, and the desired film characteristics.

- If your primary focus is coating a complex, 3D object with a uniform film: CVD is almost always the superior choice due to its non-line-of-sight nature.

- If your primary focus is coating a temperature-sensitive substrate like plastic: PVD is the far more suitable option because of its significantly lower operating temperatures.

- If your primary focus is depositing a high-purity or complex metal alloy: PVD sputtering often provides better control and works with a broader range of materials.

- If your primary focus is creating a thick, protective, and cost-effective coating on a durable substrate: CVD offers distinct economic and practical advantages.

Ultimately, the best deposition method is the one that aligns precisely with your substrate's limitations and your final product's performance requirements.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Conformal Coating | Uniform film thickness on complex 3D shapes, overcoming line-of-sight limitations |

| Process Flexibility | Codeposition of materials, adaptable operating conditions (atmospheric to plasma-enhanced) |

| High-Quality Films | Cost-effective thick coatings with control over composition, hardness, and conductivity |

| Trade-off: Temperature | High operating temperatures can limit use with heat-sensitive substrates |

| Trade-off: Selectivity | Coats all exposed surfaces, requiring masking for selective area deposition |

Need a high-quality, uniform coating for a complex component?

The choice between CVD and other deposition methods is critical for your project's success. KINTEK specializes in lab equipment and consumables, serving laboratory needs for advanced material deposition. Our experts can help you determine if CVD's superior conformal coating is the right solution for your application.

Contact us today to discuss your specific substrate and coating requirements and discover how our solutions can enhance your R&D or production process.

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Laboratory CVD Boron Doped Diamond Materials

People Also Ask

- What is the temperature range for CVD? It's Not a Single Number—It's Dictated by Your Materials

- What is Chemical Vapor Deposition (CVD)? Master High-Purity Thin Film and Semiconductor Fabrication

- What is the chemical vapor deposition method of carbon? Build Advanced Materials from the Atoms Up

- What are the chemical deposition processes? A Guide to CVD, CSD, and Plating

- What are the characteristics and applications of Vapour Phase Epitaxy (VPE)? Key Insights for Semiconductor Growth

- What is CVD in manufacturing? A Guide to High-Purity Material Deposition

- What are the main advantages of using CVD in CMOS technology? Unlock Precision in 3D Device Fabrication

- What are the main components of CVD equipment? A Guide to the Essential Systems