At its core, hot pressing is a powder metallurgy technique that excels at producing parts with superior density and mechanical strength. It achieves this by combining the powder compaction and sintering processes into a single, highly controlled step. This simultaneous application of heat and pressure results in minimal porosity, excellent dimensional accuracy, and the unique ability to process advanced materials that are difficult to consolidate using conventional methods.

The primary advantage of hot pressing is its ability to overcome the limitations of traditional sintering. By applying pressure and heat at the same time, it forces powder particles to bond more effectively, yielding finished parts that are stronger, denser, and more precise than those made through separate steps.

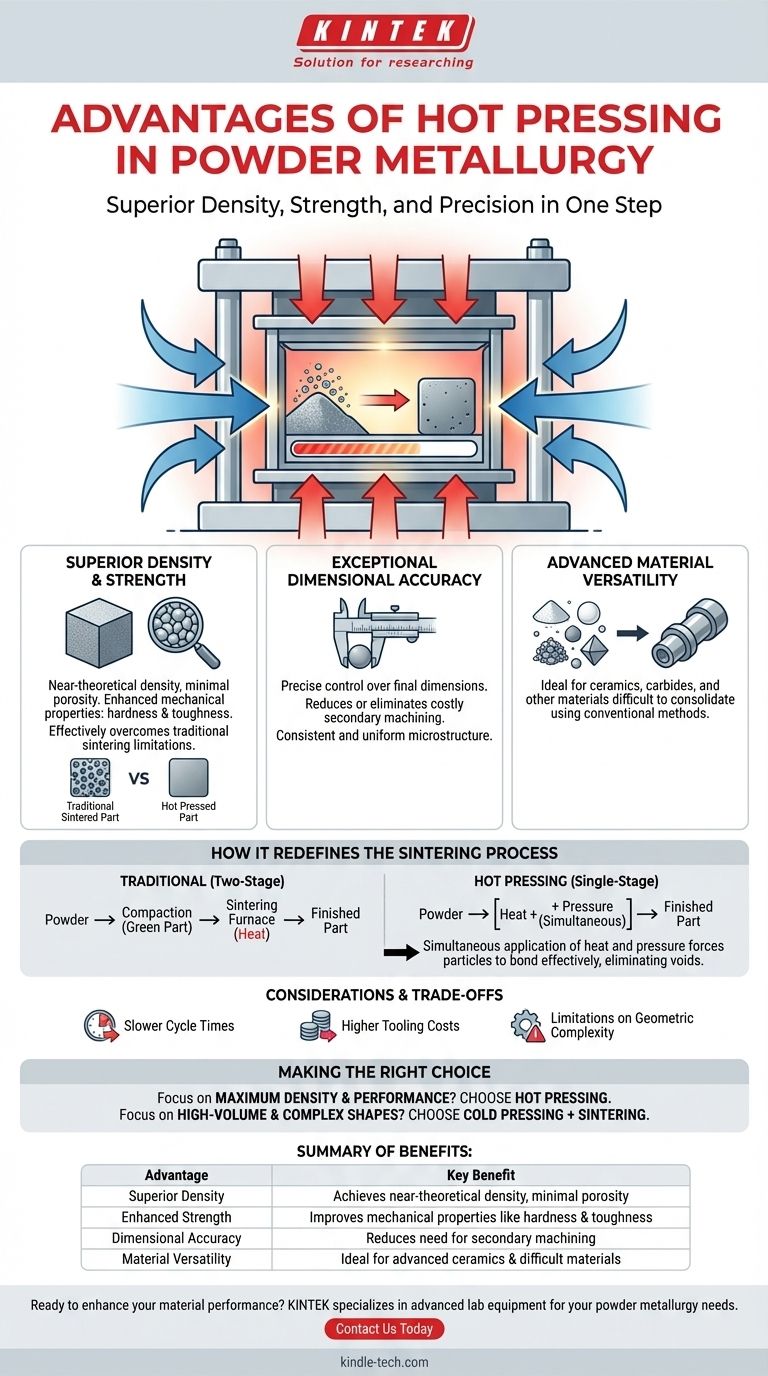

How Hot Pressing Redefines the Sintering Process

Hot pressing fundamentally alters the conventional powder metallurgy workflow. Instead of a two-stage process (compaction then sintering), it merges them into one highly effective operation.

Combining Compaction and Sintering

In a traditional powder metallurgy process, metal powder is first compacted in a die to form a fragile "green" part. This part is then moved to a separate furnace for sintering, where heat encourages the particles to bond.

Hot pressing conducts both of these actions in the same chamber. The powder is heated to just below its melting point while simultaneously being subjected to high pressure.

The Mechanism of Superior Densification

The combination of thermal and mechanical energy is the key to the process's success. The elevated temperature makes the metal particles more pliable and ready to bond.

The applied pressure then forces these softened particles together, physically eliminating the voids and pores that would otherwise remain. This action dramatically accelerates the "necking" process, where individual grains fuse to create a solid, dense mass.

Unlocking Difficult-to-Process Materials

Many advanced materials, such as certain ceramics and sintered carbides, resist conventional sintering. They have high melting points and low particle adhesion, making it difficult to achieve full density with heat alone.

Hot pressing provides the necessary force to overcome these challenges. It is the preferred method for creating ultra-hard tools and high-performance components from these specialized powders.

The Tangible Benefits in Part Quality

The unique mechanism of hot pressing translates directly into measurable improvements in the final component's characteristics.

Achieving Near-Theoretical Density

The most significant outcome of hot pressing is extremely low porosity. Eliminating these internal voids is critical for improving mechanical properties like strength, hardness, and fracture toughness.

A related technique, Hot Isostatic Pressing (HIP), uses gas pressure from all directions to achieve similar results, further reducing any microshrinkage and creating a fully dense part.

Exceptional Dimensional Accuracy

Because the part is formed and finalized in a single step within a robust mold, hot pressing offers exceptional control over the final dimensions. This precision often reduces or eliminates the need for costly secondary machining operations.

Homogenous and Uniform Microstructure

The simultaneous application of heat and pressure promotes a consistent and uniform metallurgical structure throughout the entire component. This homogeneity ensures that the part's mechanical properties are reliable and predictable.

Understanding the Trade-offs and Considerations

While powerful, hot pressing is not the universal solution for all powder metallurgy applications. Its advantages come with specific trade-offs that must be considered.

Slower Cycle Times

Hot pressing is a "low-strain-rate" process. The need to heat the die and powder, apply pressure over time, and cool the assembly makes its cycle time significantly longer than that of high-speed cold pressing.

Higher Tooling and Equipment Costs

The molds and dies used in hot pressing must withstand extreme temperatures and pressures simultaneously. This requires the use of expensive, specialized materials like graphite or superalloys, increasing the initial tooling investment.

Limitations on Geometric Complexity

While dimensionally accurate, hot pressing is generally better suited for simpler geometries. Processes like cold pressing are superior for creating parts with intricate details, fine features, or intentionally engineered internal voids, such as those in self-lubricating bearings.

Making the Right Choice for Your Application

Selecting the correct powder metallurgy process requires aligning the method's strengths with your project's primary goals.

- If your primary focus is maximum density and mechanical performance: Hot pressing is the superior choice, especially for high-performance materials like technical ceramics or carbides.

- If your primary focus is high-volume production of complex shapes: Traditional cold pressing followed by sintering is almost always more cost-effective and faster.

- If your primary focus is creating parts with controlled porosity: Cold pressing is the designated method for achieving specific structural properties, such as those needed for filters or self-lubricating bearings.

Ultimately, selecting hot pressing is a strategic decision to prioritize material integrity and performance over production speed and initial tooling cost.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Superior Density | Achieves near-theoretical density with minimal porosity |

| Enhanced Strength | Improves mechanical properties like hardness and toughness |

| Dimensional Accuracy | Reduces need for secondary machining |

| Material Versatility | Ideal for advanced ceramics and difficult-to-sinter materials |

Ready to enhance your material performance with hot pressing?

At KINTEK, we specialize in providing advanced lab equipment and consumables tailored to your laboratory's specific powder metallurgy needs. Whether you're developing high-performance ceramics or sintered carbides, our expertise can help you achieve superior part density and mechanical strength.

Contact us today via our Contact Form to discuss how our solutions can optimize your process and deliver the material integrity your projects demand.

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- Automatic Laboratory Heat Press Machine

People Also Ask

- Why is a vacuum environment necessary for SiCf/TC17/TB8 composites? Key to Titanium Alloy Integrity

- What specific processing conditions does a vacuum hot pressing furnace provide for the sintering of FeCrAl composites?

- What are the advantages of hot pressing? Uniaxial vs. HIP for Superior Part Density & Performance

- How does a vacuum hot-press sintering furnace facilitate the high transmittance of Pr, Y:SrF2 ceramics? Unlock Density

- What role does a high-temperature hot press play in the sintering of NITE-SiC? Optimize Your Densification Process

- How does a high-temperature hot press furnace facilitate in-situ synthesis? Master Reactive Hot Pressing (RHP) Dynamics

- How does a graphite resistance vacuum hot pressing furnace facilitate the densification of hard-to-sinter ZrB2 ceramics?

- What is the difference between spark plasma sintering and flash sintering? A Guide to Advanced Sintering Methods